#Spinning

Automation solutions made by Oerlikon

‘Where the future is coming together’

For many, mechanical looms are the embodiment of the first industrial revolution. Today – following the introduction of production line manufacturing and the advent of electronics within the production chain – the textile and fiber industry is on the verge of entering the so-called fourth industrial revolution – or Industrie 4.0 for short. With the acquisition of AC-Automation in Bernkastel-Kues and Augsburg, Oerlikon Manmade Fibers – the leading solutions provider within the manmade fiber manufacturing sector – has now set a further milestone on its journey towards fully-automatic, digitally-networked fiber production. In the future, Oerlikon textile industry customers will receive production systems together with the automation logistics – including packaging and high-bay warehouse solutions – from a single source.

In the Oerlikon Manmade Fibers segment’s new automation division, in excess of 80 specialists draw on more than 30 years of experience in manmade fiber production automation. Here, they have been closely collaborating with the Oerlikon Group as far back as the early-1980s. With the help of its highly-developed and tried-and-tested robot handling, packaging, transport and warehouse systems, Oerlikon is now creating turnkey, integrated production and logistics solutions for all customers across the globe.

“With the takeover and integration of the automation solutions from AC-Automation, we are creating new impetus for the manmade fiber business. In conjunction with our new digitalization solutions, it will also enable us to clearly position ourselves as a supplier of Industrie-4.0 solutions”, states Georg Stausberg, CEO of the Manmade Fibers segment, talking about the reasons for the acquisition. The target is the so-called ‘digital factory’, where production systems monitor, control and optimize themselves with the help of collated data and information. Here, the manufacturing process is becoming increasingly flexible.

“Industrie 4.0 is not just a marketing buzzword”, explains Rolf Gänz, Managing Director of the Oerlikon Manmade Fibers segment’s automation division. “Imagine a company requires fibers for airbags. Even the fiber producer has to be familiar with the precise safety-relevant composition specifications. The same applies to the downstream quality control, with the finished yarn packages ideally tagged in such a way that the machines used for manufacturing the airbag fabric notices whenever the incorrect yarn package has been selected for producing the warp beam.”

All this is now possible as a result of the expanded product portfolio because Oerlikon is offering seamlessly-coordinated production, quality assurance and packaging systems without malfunction-prone and maintenance-intensive interfaces. All customers receive optimally planned, flexible systems from a single source from the very outset.

Rolf Gänz, Managing Director of the Oerlikon Manmade Fibers segment’s automation division

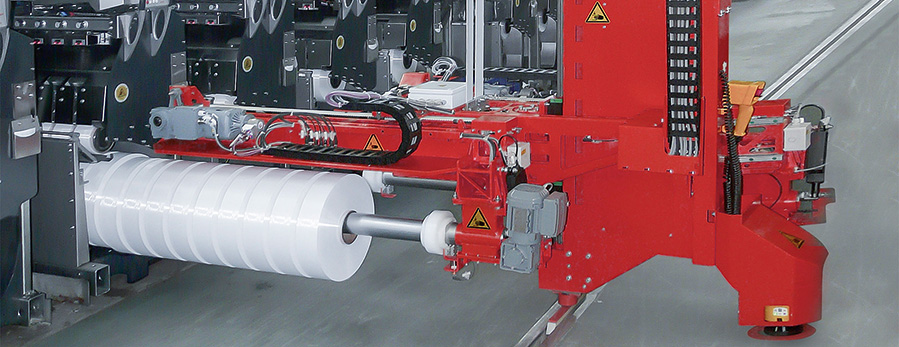

“Here, what will become the new standard in future-oriented manmade fiber manufacturing is coming together. The automation solutions will be an integral part of an Oerlikon Manmade Fibers segment Industrie 4.0 solution. It will assume the yarn product precisely at the point at which spinning plant solutions have extensively completed their work. This will create a coherent product chain – from the raw material through to final delivery. We are now offering all stages – from production planning, production tracking, quality control, packaging and palletizing – on a single, new Oerlikon platform. So, there are now no longer any annoying data interfaces. Yes, we can now also take all automation considerations into account when designing the systems, which means that our customers can now acquire the entire process chain from a single source.”