#Spinning

Köksan invests in China relying on Oerlikon Barmag Continuous Polycondensation Technology

As part of this comprehensive cooperation agreement, Köksan will invest a high triple-digit million Chinese Yuan amount in the coming years. The new plant will be in the Yangkou Chemical Industrial Park, Rudong County, Nantong, China. Köksan will be setting up its plant with a production capacity of 2.2-million-tons-per-year green polyester new materials for the packaging industry. The first phase of this project has now been officially launched. Production is scheduled to start in mid-2026.

“We are convinced that this investment will be a major step for our company's future. It is our first investment in China and one of the largest industrial investments by a Turkish company in this area of industry in China. Upon the completion and full operation of this project, Köksan will become one of the global giants in polyester production for the packaging industry”, said Murat Köko?lu, CEO of Köksan. “We are very pleased that Köksan has chosen our innovative CP technology. This is further proof of our capabilities in the field of polymerization technologies”, said Zhong Ming, General Manager of Oerlikon Barmag Huitong Engineering.

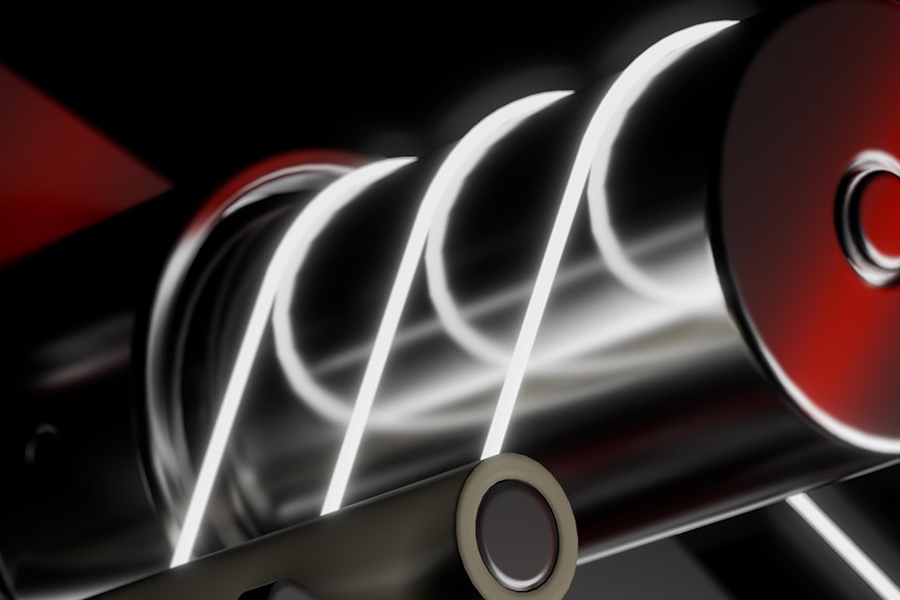

Latest CP technology from Oerlikon Barmag Huitong Engineering

The project adopts the advanced five-reactors process and tailor-made equipment of Barmag’s joint venture partner OBHE. Using purified terephthalic acid (PTA) and ethylene glycol (MEG) as raw materials, it produces high-viscosity chips through the direct esterification and continuous polycondensation process technology route. Combined with Köksan's experience & knowledge, high-quality bottle-grade polyester chips are finally obtained.

As one of Türkiye’s leading companies in the PET and plastic packaging sector, Köksan exports to more than 100 countries and maintains its investments abroad. Köksan is an international investor with operations in China, Senegal, Libya, and Iraq. After over 50 years of development, the company has realized a diversified development model integrating chemical production and processing, logistics, warehousing, international trade, hotel and real estate development.