#Spinning

Barmag at the Domotex Middle East

Focus on sustainability at the trade fair

The trade fair presentation will also focus on the topic of sustainability. Together with partners such as Oerlikon Barmag Huitong Engineering (OBHE) and BB Engineering (BBE), Barmag will be presenting concepts for mechanical and chemical bottle recycling as well as for textiles, biopolymers and the circular economy. In addition, the company has been offering innovative solutions for the textile industry with the e-save sustainability label for decades, setting standards for a more environmentally friendly future.

Recycling - technologies for a sustainable future

The Homogenizer from OBHE enables thermomechanical recycling of polyester waste. Commercially available raw materials such as bottle flakes or post-industrial waste and film waste are processed into high-quality PET products. With an optimized residence time spectrum, the OBHE Homogenizer ensures constant polymerization conditions. This has a targeted effect on the desired increase in viscosity and produces an excellent and homogeneous melt quality. The production of high-quality and defined rPET products with further processing of the melt to POY and FDY in the direct spinning process or for the production of PET chips is thus guaranteed and has already been proven by installed systems on the market. With the Homogenizer, the customer receives a flexible system for thermo-mechanical recycling of polyester waste.

The VarioFil® R+ compact spinning system from BBE recycles and processes PET bottle granulate, and PET waste produced during start-up directly back into POY. The sustainable machine concept allows a high degree of product flexibility, including the production of spun-dyed yarn. The turnkey spinning line is also ideal for producers who manufacture small batch sizes or specialized products.

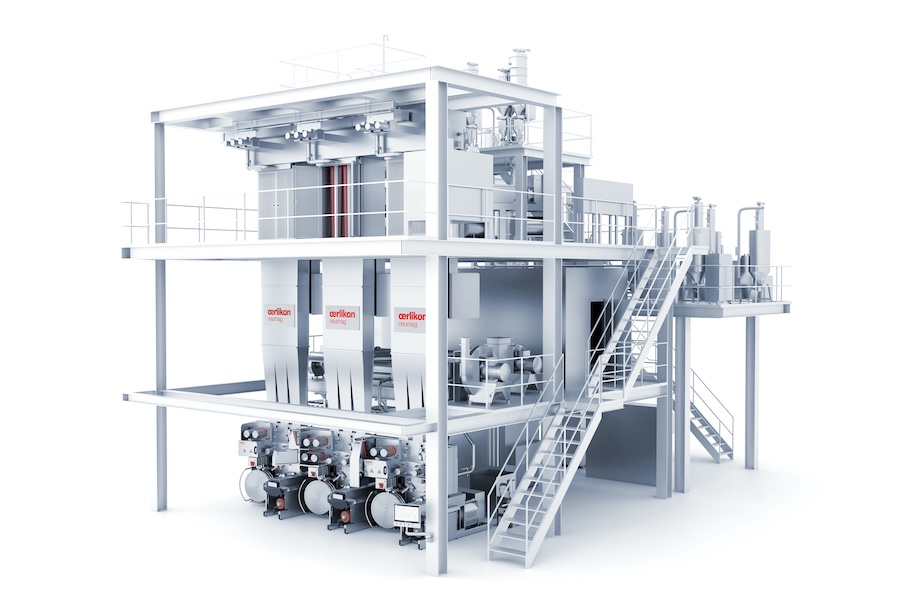

BBE's VacuFil PET recycling system convinces with the "From Waste to Value" principle. The system is designed to process textile waste to a high quality. Based on decades of experience in extrusion, filtration and spinning, the patented technology is unique: it combines gentle large-area filtration with targeted IV regulation for consistently excellent rPET melt quality, comparable to virgin material. Numerous input materials can be processed: In addition to the usual bottle flakes, VacuFil is particularly suitable for production waste from the spinning mill, from start-up lumps and yarn to unmixed fabrics, which can also include post-consumer waste. The patented key component Visco+, a liquid-state polycondensation system, quickly and reliably removes volatile impurities and automatically regulates the IV. There are various options for further processing of the treated melt. It can be fed into the main melt stream, processed into chips via pelletizing or flow directly back into the spinning mill. The VacuFil recycling system can therefore be designed modularly and flexibly to meet customer requirements.

Novel bi-component BCF yarn for the carpet market

Quality, efficiency and performance - with its latest development in bicomponent yarns for carpet production, Barmag’s product brand Oerlikon Neumag meets the carpet market's demand for new innovative BCF yarns. The new BICO BCF yarn is characterized by a richer and higher volume while significantly reducing raw material consumption in carpet production. "At the exhibition stand, interested parties can see sample yarns and carpets, find out about the range and have in-depth discussions about the benefits of BICO BCF yarn in various applications," explains Jilali Lakraa, Regional Sales Director at Barmag.

Efficient production of high-titer products in the POY and DTY process with WINGS HD and eAFK Big V

The knowledge of all relevant technologies in manmade fiber spinning enables Barmag to be the only manufacturer worldwide to offer a comprehensive range of services for the production of carpet yarns. The system concept based on a POY and texturing process is designed for a carpet and home textile product sector that requires particularly soft and bulky polyester yarns with BCF-like properties. The aim here is to produce yarns with a maximum count of 1200den and over 1000 filaments. Typical products are, for example, a 1200den f1152 or 600den f1152 as well as 900den f864. The machine concept consists of the well-known WINGS HD POY winder and the eAFK Big V texturing machine.

If DTY yarns up to 1200den with up to 1152 filaments are spun together from four POY bobbins 300d/288f on a DTY machine, as was previously standard, the process has a fundamental disadvantage: half of the available winding positions of the texturing machine remain unused. Here, Barmag offers the yarn producer a highly efficient solution: the spinning concept with WINGS HD take-up unit in combination with an automatic eAFK Big V multi-spindle texturing machine is currently the only solution on the market that produces excellent quality high-titer yarns with maximum machine efficiency. With this concept, the 1200den yarns are produced directly from two 600den POY bobbins.

JeTex® Air texturing from BBE enables a broad and flexible product portfolio

The JeTex® air texturing system from BBE perfectly complements the Oerlikon Barmag DTY system and enables the customer's product portfolio to be expanded to include high-quality ATY based on POY and FDY for a wide range of textile applications. The heart of the system is the texturing box developed by BB Engineering. In addition to many other state-of-the-art components from Oerlikon Barmag, it ensures gentle yarn treatment with reliable texturing effects as well as production efficiency in terms of OPEX, handling and speed.

The JeTex® air texturing system is not only available as a complete system, but also as a conversion variant for existing DTY systems from Oerlikon Barmag. This enables customers to expand or convert their product portfolio to ATY at comparatively short notice and at low cost.

VarioFil® - flexible compact spinning system for countless applications

Whether carpets and upholstery fabrics, fashion and sport or seat belts and airbags - a wide range of products is no challenge for the VarioFil® system from BB Engineering. The compact turnkey system is also ideal for producers who manufacture small batch sizes or specialized products. It is similarly flexible when processing different polymers, regardless of whether they are PET, PP, PA 6 and PA 6.6 or PBT. Customized conversion packages allow the system to be quickly adapted to constantly changing market requirements. In combination with Oerlikon texturing machines, a wide range of end products can be covered. This ranges from standard textile yarns to textured yarns with BCF-like properties.