#Spinning

FET’s game changer for the biomedical market

Unbeatable properties

UHMWPE is prized in many industries due to its extraordinary properties. The fibre is, for example, ten times stronger than steel by weight, while exhibiting outstanding abrasion resistance, low friction and high impact strength. UHMWPE fibres are also chemically inert, resistant to most chemicals and UV light and do not absorb water. They maintain performance in a wide range of temperatures and despite their toughness are extremely lightweight.

As a result, they are unbeatable in demanding applications such as high-performance ropes in maritime industrial and rescue applications. In addition, they are invaluable in ballistic protection, cut-resistant clothing and high-performance sports gear – and increasingly in medical implants.

Biomedical market

“FET has supplied many extrusion systems to the biomedical market, most notably for the production of both resorbable and non-absorbable sutures,” says FET Managing Director Richard Slack. “In exploring what else we could do in assisting these customers, it became clear that there was a need for smaller quantities of UHMWPE fibres in bespoke sizes.”

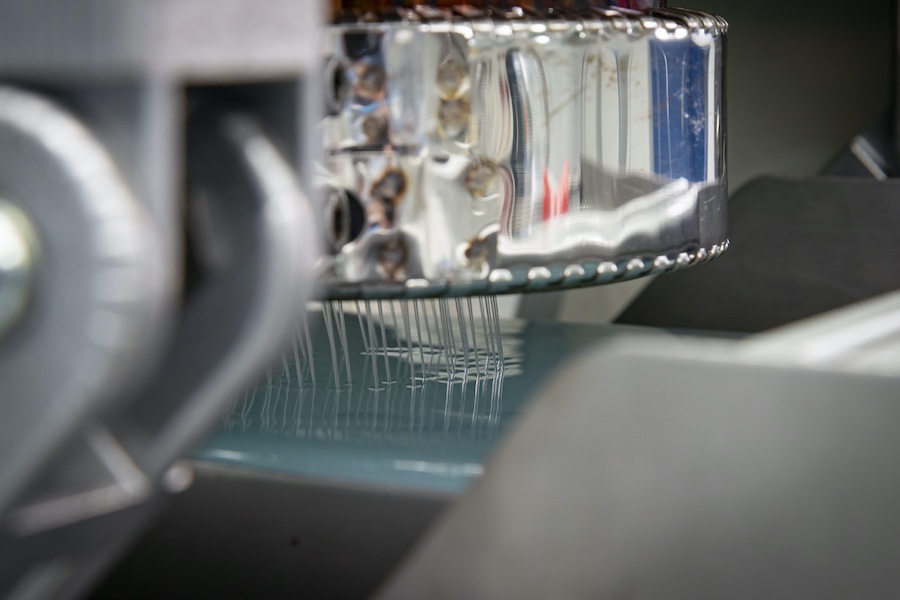

“The current systems for manufacturing UHMWPE filament yarns are on a huge scale, with very complex processing routes,” adds Research and Development Manager Jonny Hunter. “This means the supply chain is currently very inflexible with minimal opportunity for new product development. These disadvantages have been fully addressed in the development of our new FET-500 series lab and small scale gel spinning system.”

Solvent extraction

A major FET innovation is the introduction of a patented batch system for solvent extraction exploiting supercritical carbon dioxide (CO2).

UHMWPE production, until now, has involved the use of large volumes of hazardous solvents such as dichloromethane (DCM) or hexane. The UHMWPE powder is mixed with mineral oil to form a gel which is subsequently extruded, cooled and solidified. The oil is then extracted from the fibres using DCM or hexane and the solid fibres are then drawn at high temperature to further align the polymer chains, resulting in final strong and tough fibres. Typically, it takes 10 kg of Hexane to extract 1 kg of oil.

“Solvent reclamation using extraction baths and hot air drying chambers is not practical for the scale of our system,” explains FET’s Senior Material and Process Scientist Kris Kortsen. “The current baths employed can be up to 200 metres long and the waste volumes are considerable. Expertise is needed in dealing with such dangerous chemicals and overall the process has an immense environmental impact.

“CO2, by contrast, is a cheap and abundant sustainable solvent that is non-toxic, non-flammable and leaves no residue.”

Closed loop

FET’s closed-loop system can achieve more than 95% solvent recovery without loss of performance, resulting in residue-free UHMWPE filament yarns via a vastly improved route in terms of both safety and logistics.

A further innovation is the highly modular drawing system based on heated godet rollers, enabling flexible temperature and drawing control for new product development and the ability to be expanded at any time to meet customer needs.

A comprehensive LCA study detailing the full savings potential is currently being prepared and will be published shortly.

“Having processed over 130 separate polymers in the development of our extrusion systems, we believe the FET-500 is a game changer,” concludes Richard Slack. “We believe there is a big gap in the market for smaller quantities of UHMWPE, and our first line is now fully operational at the FET Fibre Development Centre in Leeds. We look forward to demonstrating it and discussing its full potential with interested companies from around the world.”