#Spinning

One for all - all-rounder proves itself under production conditions

Oerlikon Barmag WINGS FDY FLEX

The company set out with the aim of offering a WINGS for the entire range of polyester FDY yarns. Fast-moving trends, the demand for a wide variety of special yarn types – the textile market is currently confronting yarn manufacturers with constantly changing requirements. To meet these demands, extreme flexibility on the part of producers is essential.

Successful under production conditions

The all-rounder WINGS FDY FLEX has already impressed two Asian yarn manufacturers over the past twelve months. With Bico yarns, rPET, Full Dull and Semi Dull, Cationic Dyable and dope dyed, as well as other specialty products, the range of WINGS FDY FLEX is unique in the WINGS family. Especially in the low denier range, the new addition beats the competition by far. Hence, WINGS FDY FLEX manages the balancing act between class and mass with ease.

Another plus point: compared to the competition, WINGS FDY FLEX produces at higher speeds with the exceptionally high full winding rates that WINGS is known for. Hence, the system concept is unbeaten in terms of economic efficiency. In addition, there are the familiar features of the WINGS concept: significantly faster feeding and exceptional user-friendliness – the core competence of all WINGS family members – make production more efficient, cause less waste and increase the safety of the operating personnel. The new, patented tangling technology tailored to the flexible processes also ensures the excellent yarn processability typical of WINGS.

Part of a strong family

The WINGS FDY portfolio is complemented by the PLUS and PLUS ECO variants. Their strengths lie primarily in the economical production of first-class semi-dull and trilobal bright yarns. The WINGS concept has also been tried and tested in the PA6 process. Since its market launch in 2020, WINGS has been the first choice for polyamide 6 producers all over the world.

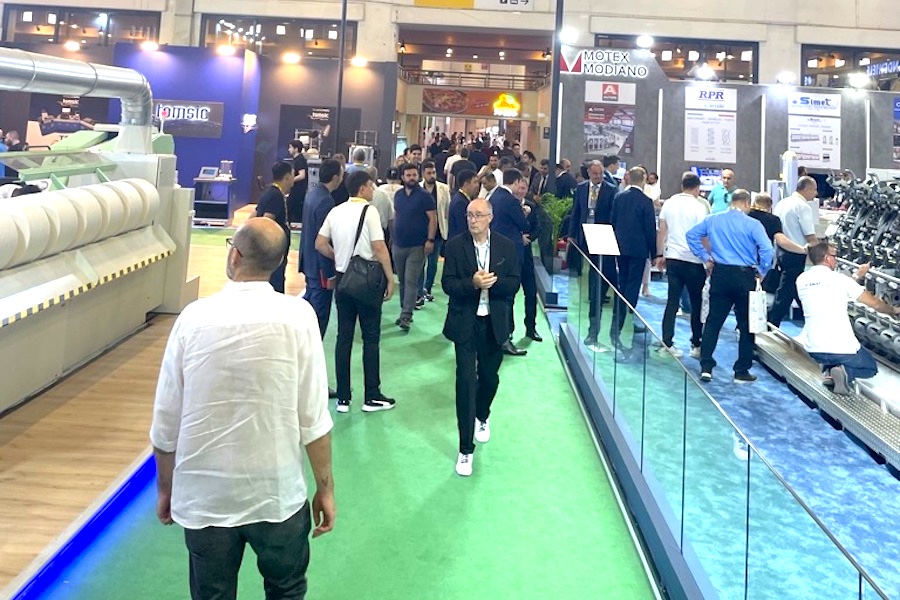

Caption 2: