#Spinning

Oerlikon Manmade Fibers Solutions continues to rely on online training center

Digital Academy hits the mark with customers

The portal is particularly effective in supporting the induction of new specialists. Whereas in the past, training was provided and documentation handed over during commissioning, today users can learn independently of time and place and refresh their knowledge at any time. The content is definitely also suitable for training technical specialists. This makes the digital approach consistent and efficient.

The technical personnel at Oerlikon Manmade Fibers Solutions provide the content for the Digital Academy. Particular emphasis is placed on practical relevance. “Our customers define who should learn what, so that the training packages are targeted and customized,” explains Tilmann Seidel, Vice President Customer Services. The BCF module is currently available worldwide in English, Spanish and Turkish.

The portal is to be made available for all processes of the Oerlikon Business Unit Manmade Fibers Solutions in the future. The digital academy for the POY process is already under development.

Digital learning is the future

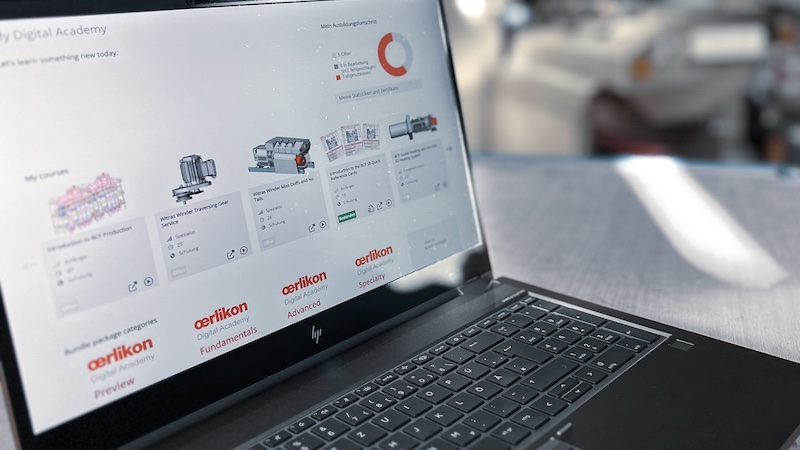

The online training center, which is located on the e-commerce platform myOerlikon.com, contains a collection of e-learning modules on the topics of operation, maintenance and repair, currently for the Oerlikon Neumag BCF machines S+ and S8. Operating personnel as well as process engineers and technicians as well as quality managers are trained.

A high staff turnover rate among yarn manufacturers, which has increased again since the Covid-19 pandemic, underscores the need for new training concepts that do not require a physical trainer and are accessible 24/7. This is because in-person training requires a considerable logistical effort, incurs travel costs and disrupts operations more severely than individually scheduled online training. This is where the Digital Academy offers a distinct advantage: compact, role-based learning units that can be accessed via mobile and stationary end devices make the content quickly applicable for the user. A success check helps to internalize the content and consolidate what has been learned. Feedback functions can quickly clarify comprehension questions at any time. Access to the Digital Academy is location- or company-specific.