#Spinning

Fancy yarns on the advance

Barmag: DTY efficiency for the future of fancy yarns

Manufacturers are faced with the task of producing complex effect structures in a precise, reproducible and energy-efficient manner. As a technology leader, Barmag offers texturing solutions that take the production of high-quality fancy yarns to the next level of performance.

Fancy yarn technology: More variety through customized process options

Varying yarn thickness, controlled effects, special surfaces and modified textures are essential for the production of fancy yarns. Barmag's texturing machines score points here with comprehensive modular options to produce yarn types such as "Cotton-like, Linen-like, Thick & Thin, Two-Tone, Different Shrinkage or Elastane-Covered. The combination of special fancy yarn devices - including hot pin, heater clip, pre-interlacing, bypass or special godets - enables producers to achieve precise, reproducible effect structures in downstream knitting and weaving applications. The product portfolio is complemented by atmos.io, Barmag's operating system for intelligent yarn production. atmos.io provides a data-based basis for decision-making: it digitizes the entire material flow, with each pack-age carrying its own data. This allows yarn manufacturers to intervene in production at any time.

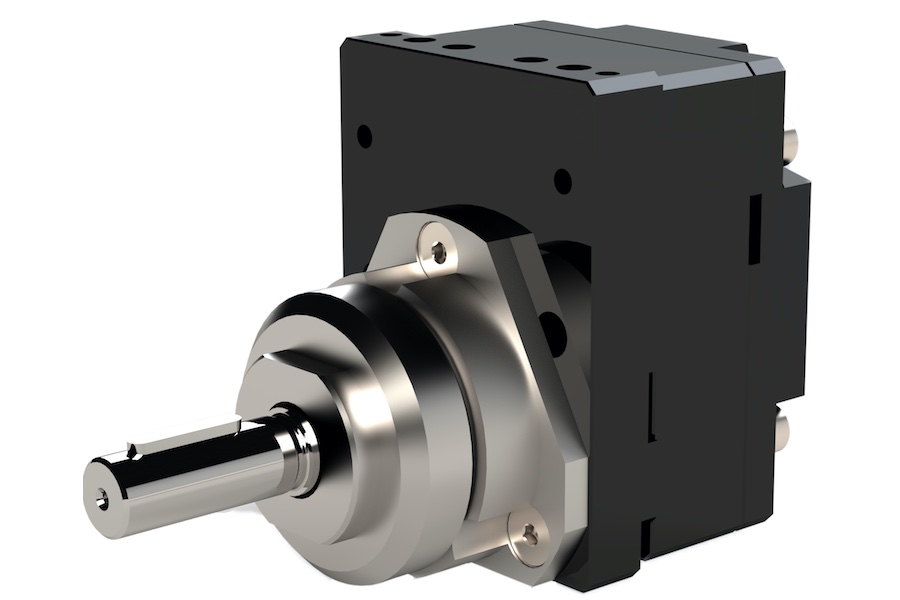

Stable yarn quality for demanding fancy applications

The texturing machines from Barmag are particularly impressive due to their ability to ensure con-sistently high yarn quality, even in complex fancy applications. The systems guarantee stable crimp characteristics, excellent uniformity and minimal effect variations. At the same time, they enable a reliable combination of POY, FDY and elastane. This performance is based on customer-focused R&D activities that specifically address current market trends - such as cotton-like and linen-like - and consistently incorporate them into the further development of technologies.

A clear advantage in the premium segment

Reproducible high-end yarn qualities are essential, especially in the fashion, home textiles and automotive sectors: creativity alone is not enough - process reliability, efficiency and consistency are just as crucial. This is where Barmag sets standards. Thanks to the close integration of quality, flexibility, efficiency, digitalization and safety, the DTY machines offer a premium solution for the economical production of modern fancy yarns.

More process stability, more added value, less risk

Manufacturers benefit from significantly more stable processes, higher added value and noticeably reduced quality and production risks - especially in sensitive premium segments. This makes the production of fancy yarns not only more creative and versatile, but also more measurable, plannable and economical