#Spinning

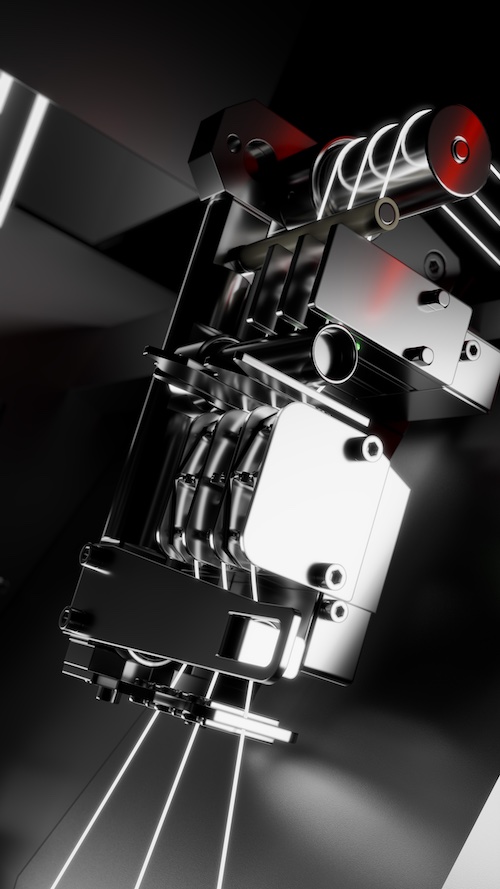

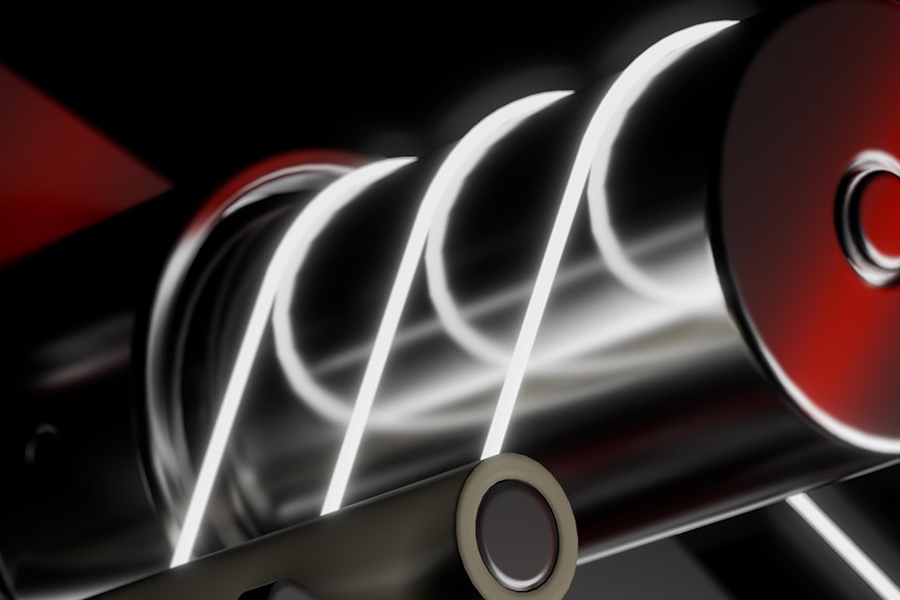

New FiberGuard BCF yarn tension sensor

Monitor, adjust, perfect

In FiberGuard BCF, sensors and software ensure that process stability and product quality are sustainably improved. The intelligent system continuously measures the yarn tension between twisting and winding in real time. If there are deviations in the yarn tension, FiberGuard BCF automatically intervenes and adjusts the process independently. The result is less waste, higher efficiency, and greater sustainability.

Operators can use the HMI to call up live data, define individual reporting thresholds, and activate automatic adjustments. In addition, the system enables the creation of customer-specific reference curves for yarn tension during the doffing process.

The solution has been well received by customers, says Jan Pauer, Head of Service Products in Neumünster and responsible for the new system: “Our discussions with interested BCF producers at ITMA Asia have shown that we have listened to our customers. FiberGuard is the next step in all Neumag BCF processes. The combination of hardware and intelligent software opens the door to a new production possibility characterized by reliable thread tension measurement and automated process adjustment.”