#Spinning

Trützschler’s will present latest technologies at CAITME 2025

Trützschler Spinning

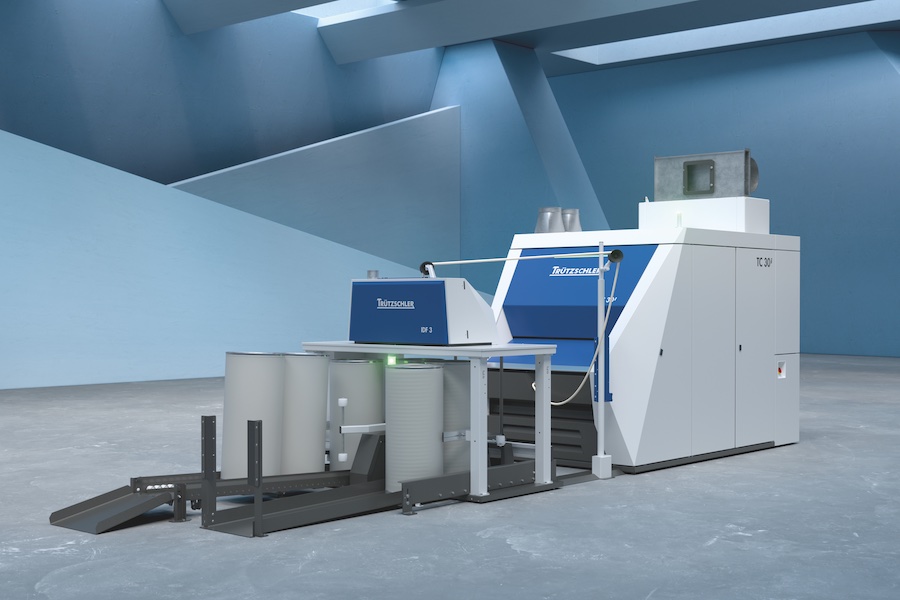

As one of the highlights at CAITME, the TC 30i exemplifies how Trützschler is shaping the future of spinning preparation. Equipped with the intelligent gap optimizer T-GO, it ensures optimal carding gaps even under changing production conditions, leading to consistent, operator-independent results. A sophisticated waste suction system enables the separate collection of different waste types, allowing more than 50% of card waste to be reused in a high-quality manner. The TC 30i also comes with the proven WASTECONTROL system, an easy-to-use and effective assurance against unnecessary fiber loss.

Visitors can also learn about the integrated draw frame IDF 3, which enables a significantly shortened spinning preparation process without compromising on quality. In fact, the IDF 3 helps to improve yarn quality levels, especially when processing raw materials with high short fiber content, and increases efficiency with a new can changing system that reduces changeover times by 3%.

Another key topic is TRUECYCLED, Trützschler’s complete solution for textile recycling. It enables partners to turn textile waste into high-quality yarns using Trützschler technology in their recycling process. A recent success story: WYRON TRUECYCLED yarn, developed and produced under license by the company Brain of Materials, is now used for certain textile surfaces in Lotus Eletre and Emeya electric vehicles. The yarn consists of 50% post-consumer textile waste and 50% recycled polyester. This example shows how sustainability and performance can complement each other in modern textile applications.

Trützschler Card Clothing

Trützschler Card Clothing (TCC) will present a wide range of technologies from its card clothing portfolio, including two key innovations: The T-WINDER, a unique piece of service equipment that ensures consistent fitting tension by indicating the actual fitting force – independent of external influences. It helps customers unlock the full potential of their carding machines while keeping costs low. The T-WINDER is compatible with all cards in spinning and nonwovens.

In addition, the Flexible Bend Control (FBC) ensures the perfect flat setting for all card models within seconds and guarantees optimum quality at all times.

See you in Tashkent, Uzbekistan! CAITME 2025 is a great opportunity to connect with our experts from Trützschler Spinning and Trützschler Card Clothing. We look forward to welcoming you at pavilion 2, booth D60 – and to sharing how our innovations can support your success in fiber processing.