#Spinning

Details matter: How Trützschler cylinder wires boost efficiency in Pakistan’s spinning sector

Next-generation GX2 and FGX2 wires extend lifetime by up to 20% and deliver superior carding quality

What do these leading mills have in common? They all rely on Trützschler Card Clothing’s cylinder wires GX2 and FGX2 wires to stay ahead. These wires are more than just tools – they are catalysts driving a new era of productivity and safety in Pakistan’s textile sector.

Proven success across leading mills From Lahore to Nooriabad, GX2 and FGX2 wires deliver measurable benefits in daily operations:

Suraj Cotton Mills Limited

Suraj Cotton Mills, operating out of Lahore, is a pioneer in fine-count yarns and operates over 125,000 ring spindles across three units. The company has been working closely with Trützschler since 1992. General Manager Shakaib Raza Zaidi reports: “Trials with GX2 and FGX2 wires on TC 15 and TC 03 carding machines delivered excellent results: A longer wire life up to 1250 tons, over 80% nep removal, grind-free operation and improved safety. These wires have become our preferred choice for sustainable, high-efficiency carding.”

Nishat Chunian Limited (NCL)

As one of Pakistan’s leading yarn manufacturers with an annual capacity of 85,000 tons, NCL, based in Lahore, runs eight ring-spinning mills and one rotor spinning plant. Technical Director Sheikh Riaz highlights: “For us, GX2 means reliability. It offers consistent quality throughout its lifecycle and lowers maintenance costs. This stability is essential for meeting our sustainability goals and ensuring smooth operations.”

Liberty

In Nooriabad, Liberty operates advanced rotor and airjet spinning facilities with 10,200 rotors and 960 MVS spindles (Vortex), producing yarns for home textiles, healthcare, and apparel. Technical Director Adnan Alam confirms: “The FGX2 wire achieved a 15–20% longer service life, consistently high carding quality, and reduces maintenance, making it a safe and reliable solution for modern spinning.”

Why GX2 and FGX2 stand out

GX2 and FGX2 wires are redefining industry standards with features that clearly set them apart from conventional competitor wires:

- Extended lifetime GX2 lasts up to 1250 tons, even with challenging cotton blends. FGX2 reaches 1200 tons – up to 20% longer than previous generations and competitor wires.

- Superior nep removal Both wires achieve over 80% nep removal efficiency, resulting in cleaner slivers and fewer downstream defects.

- Consistent quality and safety Unlike conventional wires, GX2 and FGX2 maintain stable performance throughout their lifecycle.

- Operational savings Grind-free operation means less downtime, fewer interventions, and lower maintenance costs.

Tailored solutions for different needs

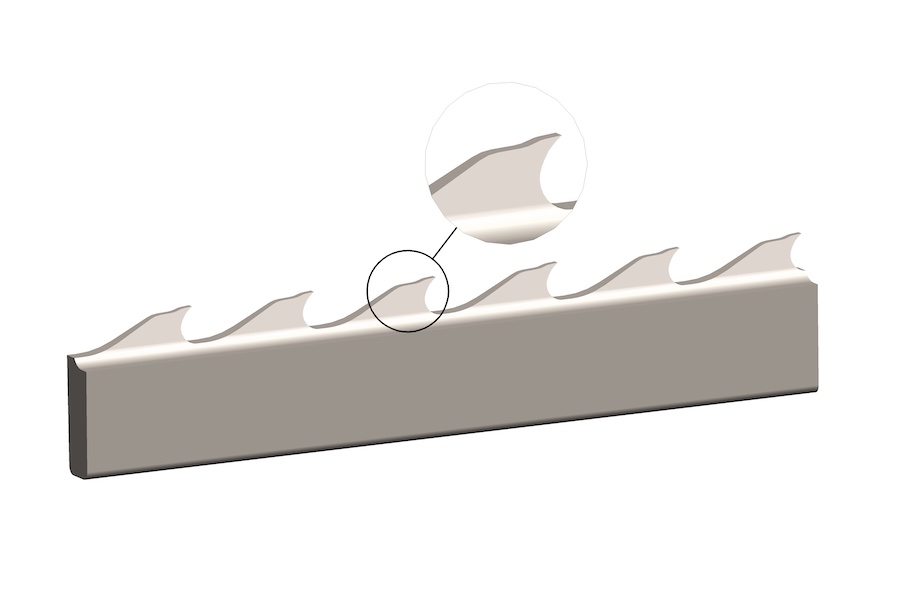

Designed for use with cotton and blends, FGX2 has an extended back that increases both tooth stability and the carding area. Thanks to this geometry, FGX2 wires enable a larger carding surface and deliver superior card sliver quality. Its maintenance-free design eliminates the need for grinding and reduces downtime – a major advantage for mills without in-house expertise or those seeking maximum efficiency.

The GX2 wire offers the same geometry but is grindable, fulfilling the demand for a wire compatible with grinding systems. Together, FGX2 and GX2 provide tailored solutions for different requirements.

Partners in Progress

In today’s competitive textile landscape, every percentage of efficiency and every kilogram of waste matters. GX2 and FGX2 are more than just wires, they are strategic partners enabling sustainable productivity, consistent quality and operational excellence.