#Research & Development

STFI opens technical center for wetlaid nonwovens

Opening ceremony attracted numerous industry and research partners to Chemnitz

With the new Center for Textile Sustainability and the installation of a wetlaid nonwovens line, the Chemnitz institute has expanded its expertise in the areas of nonwoven development, textile recycling and testing. The wetlaid nonwovens line now enables STFI to offer application-specific processing of short fibers.

The opening ceremony started with an overview of the portfolio of the Nonwovens Competence Center, which offers a unique variety of equipment and technologies. In addition to a Reicofil® 4.5 spunbond line, a laboratory-scale meltblown line and spunbond lines, both on a laboratory and semi-industrial scale, are available for research and development. Fibre nonwoven bonding at STFI is possible purely mechanically by needling, stitching or hydroentanglement as well as chemically by various binder systems. In the field of recycling, tests are possible on a combined system for random web formation using the airlay or airlaid process. With the wetlaid nonwoven system, all available nonwoven formation technologies are now installed at STFI for the first time.

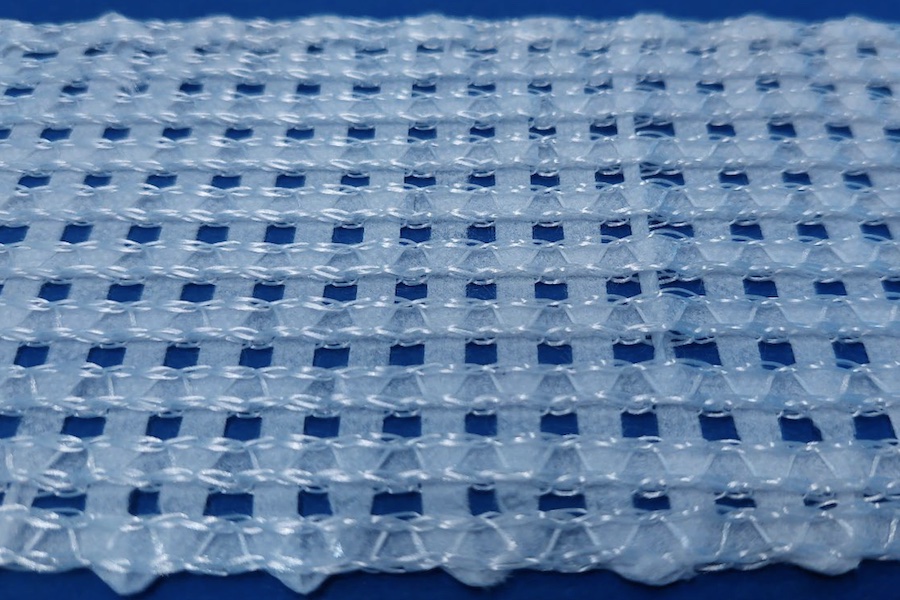

The highlight of the opening ceremony, after a short introductory lecture, was a tour of the wet-laid nonwovens line in operation. With a working width of 600 mm and a line speed of up to 10 m/min, single-layer wet-laid nonwovens can be produced. Short fibers with lengths of up to 25 mm and fiber dusts are processed in the production of wet-laid nonwovens. Almost all fiber types and materials in different lengths, thicknesses or processing states, as well as material mixtures and recycled fibers, can be processed into wet-laid nonwovens. The dispersion behavior of the fibers and the fiber length, among other things, are crucial for the product. In the first step of the process, fibers are dispersed in water to form a suspension. The suspension is then formed into a fleece on an inclined wire belt using a headbox. The fleece is then thermally bonded by adding binder fibers or by applying an additional binder. Finally, the web is dried and rolled.

Wet-laid nonwovens are characterized by high surface uniformity with low material thickness and uniform strengths in the longitudinal and transverse direction, which gives them unique material properties. In addition, they have the potential for novel material properties, such as electromagnetic shielding. Their fields of application include, among others, hygiene articles, packaging, battery separators, filter media, reinforcing structures and technical textiles in the broadest sense. Current R&D topics in wetlaid technology include not only the development of modern filter media but also the processing of recycled carbon fibers, optimization of raw materials and process parameters, and the development of battery components. In addition, STFI will in future be conducting research into the scaling and productivity increase of wetlaid nonwovens lines and into innovative material combinations.

STFI would like to thank everyone who made this day an extraordinary experience. In particular, they would like to thank the Sächsische Aufbaubank (SAB) and our partner Pill Nassvliestechnik GmbH, Reutlingen, for their support in installing the wet-laid nonwovens production line.