#Research & Development

Small tolerances, big impact and a recyclable alternative to elastane

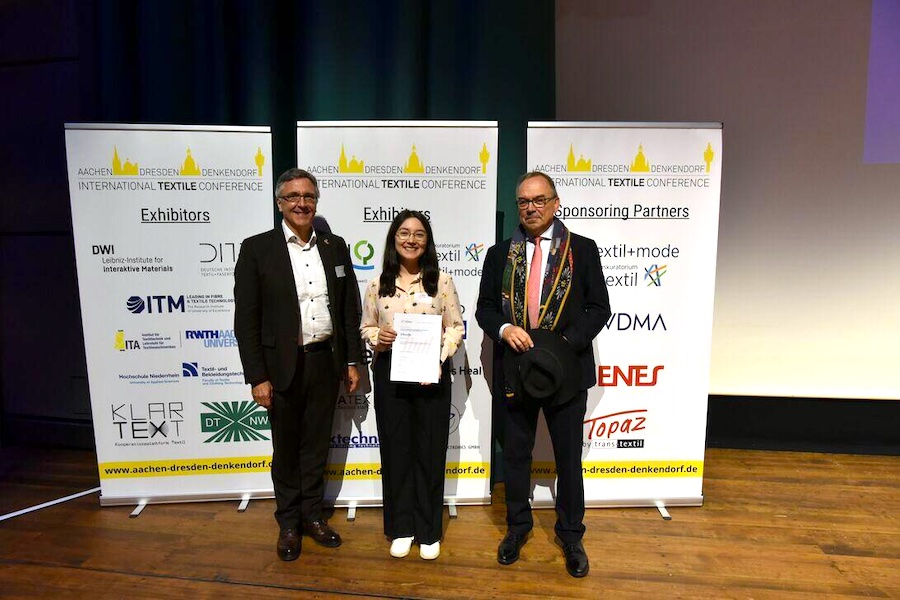

Small tolerances, big impact: A finite element study on the fabric take-up of a weaving machine

The phenomenon of “edge draw-in” — the lower warp thread tension at the fabric edges compared to the centre — can lead to inhomogeneous mechanical properties and thus to reduced fabric quality. In her master’s thesis “Advanced Numerical Modelling of Fabric Take-up Systems: Influence of Mechanical Tolerances on the Fabric”, Janne Warnecke provided an important contribution to understanding the factors influencing these tension differences across the fabric width.

She demonstrated that even small deviations of just 1 mm in the fabric take-up rollers, well within typical manufacturing tolerances, can lead to differences in tension values of more than 600%. These insights are particularly valuable for weaving machine manufacturers in evaluating the geometric design and tolerances of their take-up systems.

To achieve this, Janne Warnecke used the finite element method, modelling the take-up system of a weaving machine and examining how manufacturing tolerances within the system affect the stress distribution in the fabric. A new aspect of her work is the macroscopic modelling of the take-up system combined with the integration of geometric deviations. Including these manufacturing tolerances enables a deeper understanding of how geometric factors influence the stress state within the fabric.

For her master’s thesis, Janne Warnecke was awarded the Walter Reiners Foundation's Promotion Award, including prize money of €3,500.

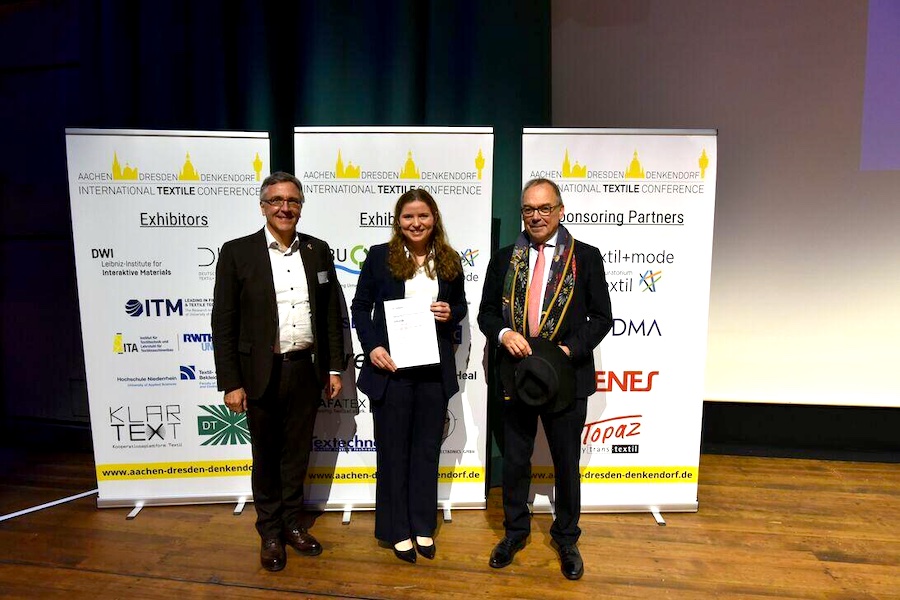

Thermoplastic elastomers as a recyclable alternative to elastane

The increasing importance of a circular economy for conserving resources and minimising negative environmental impacts requires innovative recycling concepts for textiles. The increasing use of elastane poses a particular challenge in textile recycling. Even small amounts of elastane cause difficulties in established recycling technologies such as thermomechanical recycling, for example by clogging filter media or decomposing into potentially toxic degradation products.

Jasmin Roos won the Sustainability Award for her bachelor's thesis on the topic: ‘Potential of thermoplastic elastomers for thermomechanical textile recycling as an alternative to elastane: Experimental evaluation of PET/TPC blends’ with prize money of €3,000.

In her thesis, Jasmin Roos, supervised by ITA scientist Ricarda Wissel, took an in-depth look at the development of sustainable solutions for recycling elastic textiles. The innovative approach aims to replace conventional, non-recyclable elastane with melt-spun yarns made from thermoplastic copolyester elastomers (TPC). This can not only improve recyclability, but also contribute to reducing environmental impact, as harmful solvents can be dispensed with in yarn production.

The main objective of her work was to evaluate the suitability of blends of TPC and polyethylene terephthalate (PET) for joint thermomechanical recycling. Blend and melt spinning tests were carried out on a laboratory and pilot scale at the ITA facilities. Jasmin Roos succeeded in producing blends of different proportions of PET and TPC, based on typical elastane proportions in textiles, and successfully processing them into yarns on a melt spinning line – a crucial aspect for closed-loop recycling. The results of her bachelor's thesis thus form a promising basis for the development of recyclable elastic yarns and textiles.