#Research & Development

More safety and comfort for protective clothing thanks to auxetic fabrics

Previous research in the field of auxetic fabrics has focused on fiber composites. These structures are naturally very stiff. This makes them suitable for applications where the material only needs to be deformed once. Other research approaches have achieved auxetic properties at the yarn level that return to their original shape after tension. This negative transverse contraction can be quantified using Poisson's ratio, it assumes values from ±0 but also clearly negative values for auxetic structures. However, the effect is superimposed by other structural influences in the textile surface and is thus limited. For this reason, the DITF are researching a textile, flexible structure based directly on woven fabric that has reversible, auxetic properties.

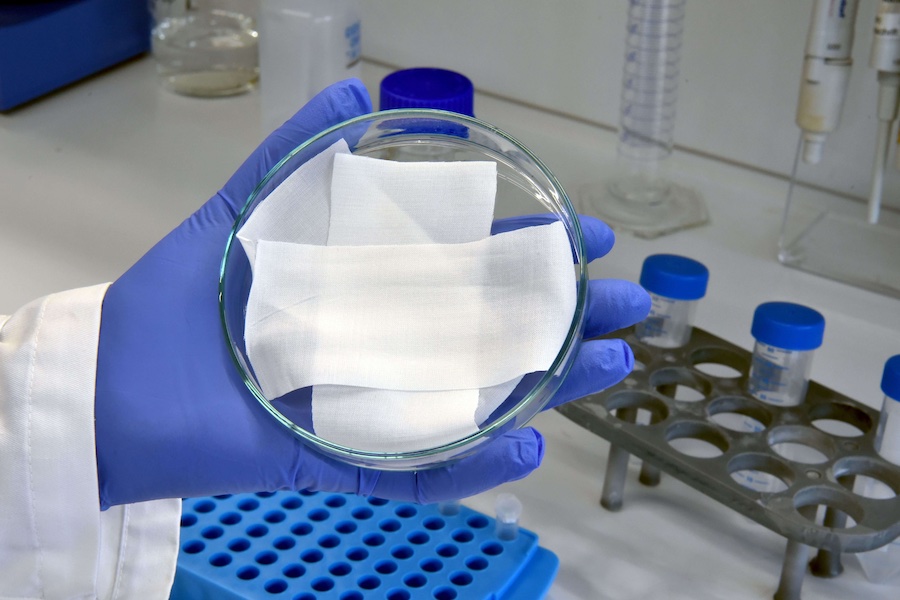

To achieve these properties, special multi-layer fabrics have been developed that resemble the thickness structure of an hourglass in both the weft and warp directions. This geometry leads to a compression of the fabric under pressure, which is advantageous in protective clothing, for example. Impacts and other forces are significantly reduced. At the same time, the structure allows for excellent adaptation to different body shapes. Conversely, the fabric becomes wider or thicker under tensile stress. This can lead to a larger surface area or volume, as desired for filtration tasks.

The fabric structures developed at the DITF as part of the research project “Auxetic Weaving Structures” (1IF22730N) thus have an adjustable Poisson's ratio with negative values down to −2. The auxetic effect is not only effective once, but can also be reliably demonstrated under repeated stress.