#Research & Development

Wellness and health: active ingredient of graviola embedded in textiles

Objective

In natural medicine, the leaves of the tropical graviola tree (Annona muricata) are used to improve well-being and treat numerous diseases. The effect of the graviola plant is mainly due to the active ingredients it contains, the so-called acetogenins. The extraction, preparation and use of these active ingredients for sustainable textile applications in the field of health and wellness have not yet been the subject of re-search yet.

Approach and results

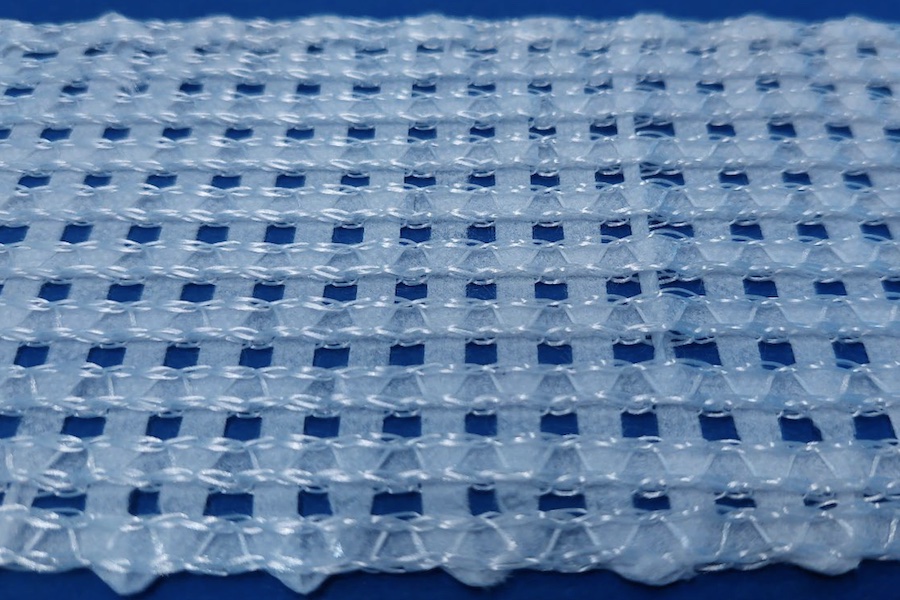

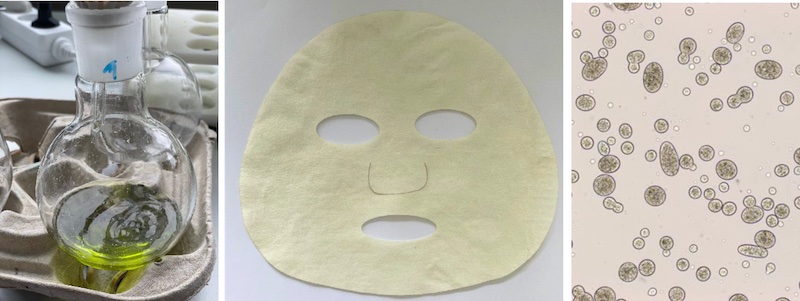

The aim of the GRAVIOLA project was to develop new types of functionalised textiles using active ingre-dients from the Graviola plant. The application of the active ingredients was analysed in two different ways: direct finishing of the textiles with different coating systems containing Graviola active ingredients, and application of microcapsules smaller than 100 microns loaded with acetogenins. The microcapsules were incorporated into suitable binder systems and applied to knitted and nonwoven fabrics. The micro-encapsulation of the Graviola extract ensures that the active ingredient is released over a defined period of time. Essential textile properties such as colour fastness, water resistance, rub fastness and human ecological requirements were taken into account.

By incorporating aqueous microcapsule suspensions into suitable binder systems, the microcapsules were fixed in such a way that problem-free processability of the textile material is guaranteed and the release of the active ingredient can be maintained over a defined period of time.

Due to their anti-inflammatory and health-promoting effects, textiles treated with Graviola ingredients offer a wide range of dermatological applications in the wellness and health sector as well as sustainable use in the textile life cycle.

Functional samples were produced on the basis of a) microcapsules and b) Graviola extracts: "sheet masks" made of viscose nonwovens for the beauty and wellness sector as well as single jersey knitted fabrics with Graviola extract and encapsulated active ingredients, combined with aloe vera oil, for thera-peutic clothing for skin treatment.

Co-operation partners

In this CORNET research project, the German research centres Sächsisches Textilforschungsinstitut e.V. (STFI), Chemnitz (Germany), and Fraunhofer Institute for Applied Polymer Research (IAP), Potsdam (Ger-many) cooperated with the Czech research centre INOTEX, Dv?r Kralove n.L. (Czech Republic). The pro-ject was supported by the research associations Forschungskuratorium Textil e.V. (FKT), Berlin (Ger-many) and Clutex - klastr technické textilie, Liberec (Czech Republic).

Further information: www.stfi.de