#ITMA Asia + CITME Singapore 2025

Mayer & Cie. at ITMA Asia

Important industry event

ITMA Asia + CITME is the leading trade fair for textile machinery in the Asian region – and thus in the world's largest sales market. It brings together the international market leaders in the industry and offers a platform for the exchange of information on the latest technologies, sustainability and digitalization. Benjamin Mayer, Managing Partner of Mayer & Cie., says: "For us, ITMA Asia is both an opportunity for customer loyalty and a door opener for new business relationships in one of the most dynamic textile regions in the world."

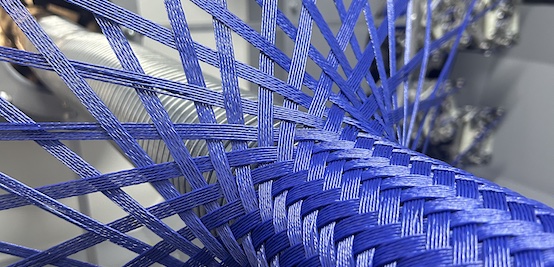

OVJA 2.4 EC II

"The OVJA 2.4 EC II belongs to our product group of circular knitting machines, which are engineered in Germany and manufactured in our factory in China”, says Benjamin Mayer, explaining the machine exhibit at ITMA Asia. “These machines are predominantly aimed at customers from China and Southeast Asia.” Thanks to a new system for single needle selection, the machine impresses with a significantly reduced cylinder height. In addition, fewer knitting elements are required, which significantly reduces the energy consumption of the machine. The OVJA 2.4 EC II produces fabrics for sports and leisure wear; it is also widely used in the field of home textiles, especially mattress cover fabrics – and all this at an attractive price.

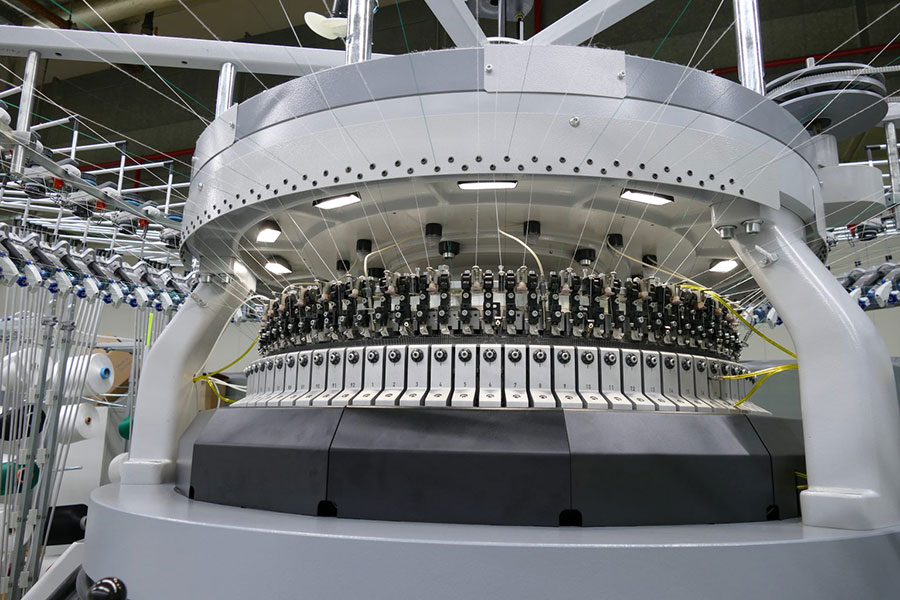

Circular knitting machines that set standards

Four machines from Mayer & Cie. set standards in their respective sectors: The D4 4.4 HPI is the world's most productive circular knitting machine for interlock fabrics. Depending on the machine and yarn parameters, it achieves an output of up to 600 kilograms of fabric per day. The range of applications for knitted fabrics is diverse, from underwear, nightwear to home textiles, linings and carrier materials.

When it comes to double jersey structures, the OV 3.2 QCe is a first-class solution. It can produce up to 650 kilograms of fine rib 1:1, elastomer platted, per day. Typical areas of application for this tried-and-tested machine – it is one of Mayer & Cie.'s best-selling machines – are sports, leisure and outerwear fabrics.

The two Relanit machines Relanit 3.2 HS II and Relanit 4.0 are second to none in the single jersey sector. The Relanit 4.0 produces up to 1,700 kilograms of plain single jersey every day, while the Relanit 3.2 HS II brings extra expertise in elastomeric plating and achieves an output of up to 970 kilograms of fabric per day. Thanks to relative technology, both machines are exceptionally gentle on yarn and energy efficient.

New Control 5.0 machine control system

The new Control 5.0 machine control system for circular knitting machines from Mayer & Cie. has been available since early summer 2025. It makes Mayer & Cie. circular knitting machines Internet-ready – and thus fit for the digital future of textile production. Control 5.0 is a prerequisite for knitlink, Mayer & Cie's digital platform. It is available as an upgrade kit for all machines built from 2001 onwards and is now part of every newly delivered mechanical circular knitting machine.

knithawk

knithawk is a tool for optical defect detection. It sits directly at the knitting point, where the knitted fabric is made. The camera unit, which "scans" the knitted fabric using infrared light, is quickly installed. If knithawk detects a serious or recurring error, the machine is stopped. The tool also creates an error log.

In this way, knithawk can prevent knitting errors from continuing through many meters of knitted fabric. Thanks to knithawk, resources such as water, natural fibers, polyester and energy are not used for nothing.

knithawk is available for single jersey machines from Mayer & Cie. Customers can order it directly as part of their new machines or equip existing machines with knithawk via upgrade kit.

120 years of Mayer & Cie.

The year 2025 is an anniversary year for Mayer & Cie.: On July 8, 2025, the family-owned company celebrated its 120th birthday. The green MCT emblem stands for precision, durability and reliability worldwide, in the field of circular knitting machines as well as in braiding machines.

"We are proud to have taken this path – and we will continue to do so with innovative strength and reliability", says Managing Director Benjamin Mayer.

However, current conditions cast a shadow over the anniversary year. The order situation remains tense in the German textile machinery industry. In view of the various crises worldwide, a trend reversal is not yet in sight. It is difficult for Benjamin Mayer to give an outlook for the future: "We are well positioned as a company, have answers to the needs of the market and modern processes in production. But no one can predict how the world situation and with it the economic situation will develop."