#Carpets

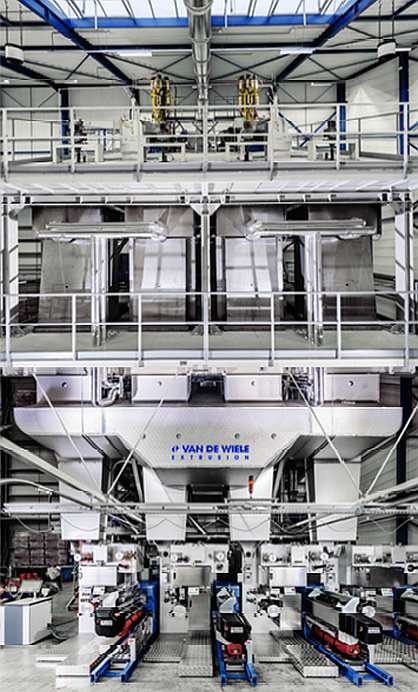

Van de Wiele Extrusion delivers first BCF Extrusion line to Turkey

The Van de Wiele BCF extrusion lines are based on a 3-end system with following specifications:

- Multi- or single polymer executions

- Modular system(s) starting from 1 extruder with 2 positions = 6 ends

- Newly developed texturing device without lamellas:

- Improved plug cooling for higher crimp stability.

- Highly consistent and repeatable crimp values.

- Gravimetric dosing system

- Short melt pipe between extruder and spinning beam.

- Round bottom loaded self-sealing spin pack

- Reinforced floor panel of the quench cabinet which can be opened/closed pneumatically

- Maximum output 40-42 kg/h/end at 100% efficiency

- Newly developed 3-ends winder:

- Traverse system with multiple wings.

- Cooler bobbins due to low friction winding.

- Perfect bobbin shape.

- Smooth doffing for gentle yarn treatment.

Van de Wiele started their BCF Extrusion project in August 2012. First goal was to develop and install a pilot line in Marke, Belgium. This pilot line was shown to the customers of Van de Wiele during the open days in October 2013.

The second goal was to develop and install the first serial line in Marke, Belgium. This line was up and running in November 2014. Several customers visited this line after the start-up. Both pilot line and serial line are mono colour BCF lines and able to produce polypropylene, polyamide 6 and polyester BCF yarns.

Van de Wiele Extrusion provides solutions for the manufacturing of BCF-yarns needed for area rugs, relief carpets and wall to wall carpets. Van de Wiele utilizes the know-how between weaving, tufting & extrusion to produce the best suitable yarn for the different carpet types produced.