Spinning

2025-12-11

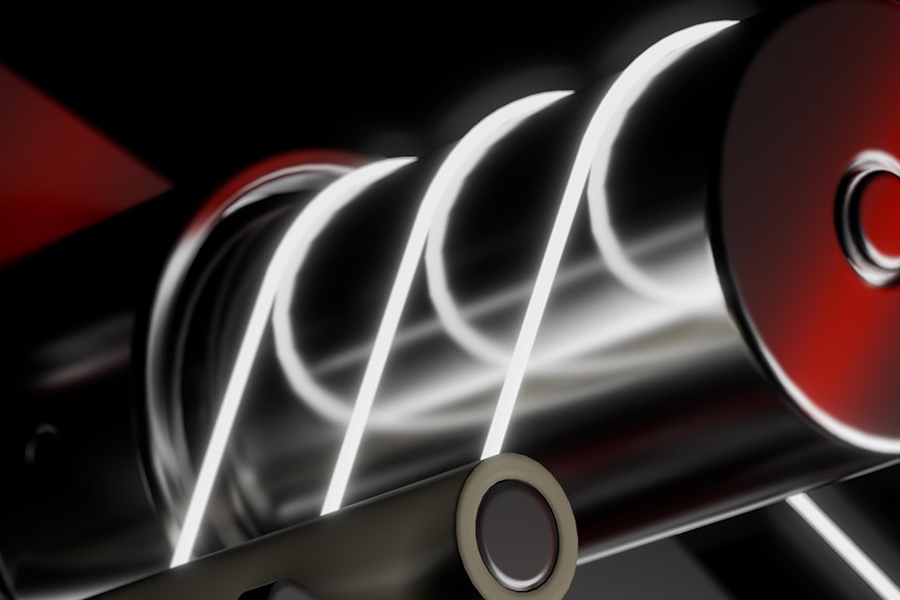

With the successful commissioning of a multi-digit PA66 spinning line for microfiber yarns, Chinese textile company Shandong Nanshan Fashion Technology Co., Ltd. has added yarn production to its textile value chain.

...more

Spinning

2025-12-11

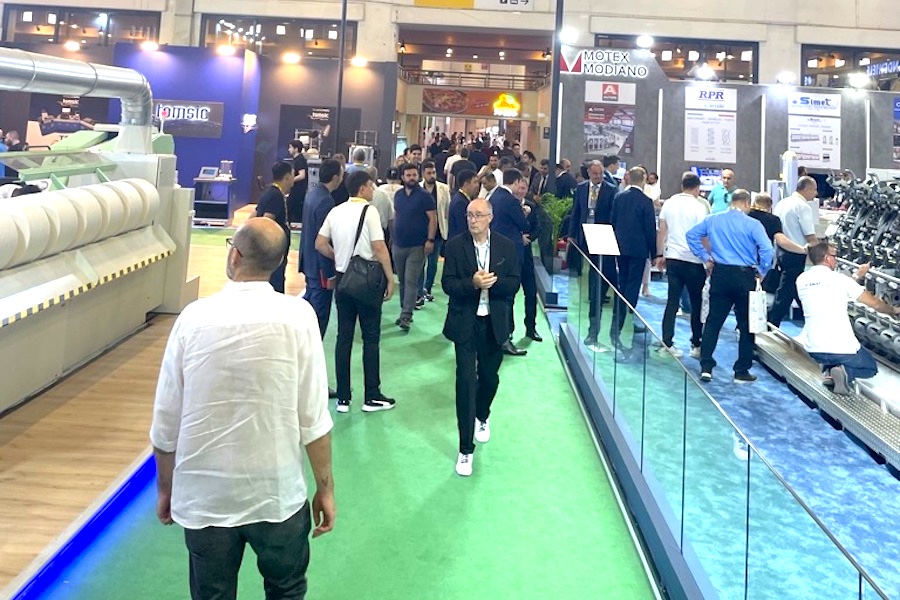

Saurer Technologies Twisting Solutions, a global leader in textile machinery innovation, will be present at the International Carpet and Flooring Expo ICFE 2026. Join us January 6–9 at the Istanbul Expo Center, Türkiye, as industry leaders, manufacturers, and innovators gather to explore the latest breakthroughs in carpet and flooring technology. Let’s meet at the new established global Center of the Carpet Sector in hall 3, booth 300!

...more

Spinning

2025-12-11

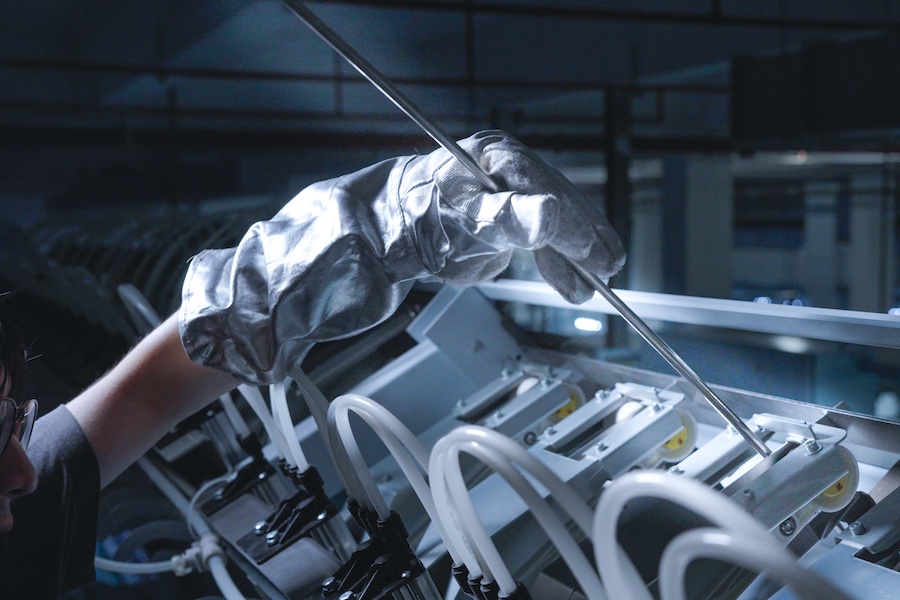

Pakistan’s textile industry, especially its spinning sector, is the backbone of the national economy and a vibrant hub of innovation. Today’s spinning mills face growing demands for efficiency, quality, and sustainability. From the serene northern valleys to the vibrant port city of Karachi in the south, mills like Suraj Cotton Mills, Liberty, and Nishat Chunian are turning to advanced solutions.

...more