Texprocess 2015

2015-05-04

Texprocess Innovation Award 2015 goes to VEIT Fusing 4.0

VEIT has won this year’s Texprocess Innovation Award. The jury paid tribute to VEIT’s Fusing 4.0 concept to achieve interoperability in line with the German idea of a futureoriented „Industry 4.0” - for a flexible, efficient and sustainable fusing process.

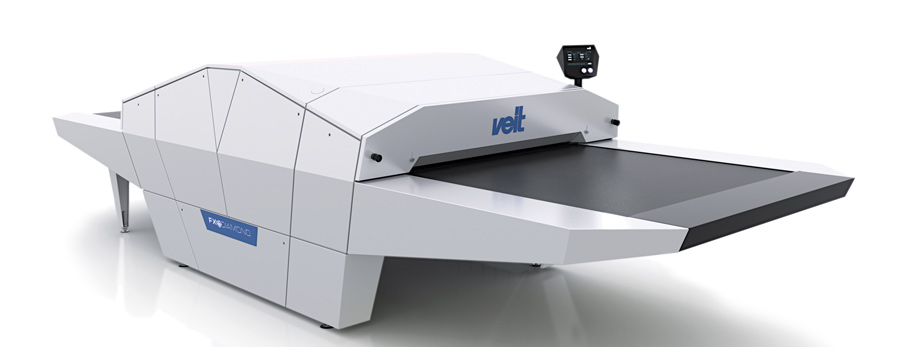

VEIT Group fusing machines with intelligent networking functionAt this year’s leading international trade fair for processing textile and flexible materials, VEIT Group launched the VEIT FX Diamond fusing machine with Fusing 4.0. Fusing 4.0 enables the machine to communicate with itself, with materials and with other machines through a decentralised fusing control process. It thus meets the criteria for intelligent manufacturing and can interconnect product development, manufacturing, logistics and customers with each other. „We highly appreciate this Award“, says VEIT Group President Günter Veit. „We are sure that, with Fusing 4.0, we have set the course for the manufacturing process of the future. “. The company took over the fusing machine business from Kannegiesser in 2001 and has continuously been improving the technology ever since – achieving the perfect synthesis of Kannegiesser technology and VEIT innovative strength.

The benefit from the sensor-based, network-compatible technology of VEIT Fusing 4.0 is that the manufacturing process is simplified and made more efficient. Materials for fusing that have been equipped by the manufacturer with an RFID or 1D or 2D codes can be automatically identified by the fusing machine. Processing parameters such as temperature, pressure and speed are automatically set, monitored and documented. This permanent monitoring and control guarantees consistent quality and optimal finishing performance for every fusing material. In addition to its communication with the goods to be fused, the machine’s ability to self-monitor is another major innovative feature. All the components that are essential for trouble-free operation of the machine constantly self-monitor for wear and tear, malfunctioning and cleanliness. A diagnosis screen immediately shows the exact location of any error – also to partners that communicate with the machine through the network.

In the automotive and various other industries, supply chains are already in place, with full interoperability of coordination and control functions. VEIT FX Diamond Fusing machine with VEIT Fusing 4.0 is perfectly suitable for use in these production and supply chains. Intelligent communication leading from machine sensors to the internet permits its smooth integration into inter-company supply chains, provides data in real time and allows flexible reactions to unforeseen circumstances. In the event of supply shortages or other bottleneck situations, for instance, the low-energy standby mode is activated.

The benefit from the sensor-based, network-compatible technology of VEIT Fusing 4.0 is that the manufacturing process is simplified and made more efficient. Materials for fusing that have been equipped by the manufacturer with an RFID or 1D or 2D codes can be automatically identified by the fusing machine. Processing parameters such as temperature, pressure and speed are automatically set, monitored and documented. This permanent monitoring and control guarantees consistent quality and optimal finishing performance for every fusing material. In addition to its communication with the goods to be fused, the machine’s ability to self-monitor is another major innovative feature. All the components that are essential for trouble-free operation of the machine constantly self-monitor for wear and tear, malfunctioning and cleanliness. A diagnosis screen immediately shows the exact location of any error – also to partners that communicate with the machine through the network.

In the automotive and various other industries, supply chains are already in place, with full interoperability of coordination and control functions. VEIT FX Diamond Fusing machine with VEIT Fusing 4.0 is perfectly suitable for use in these production and supply chains. Intelligent communication leading from machine sensors to the internet permits its smooth integration into inter-company supply chains, provides data in real time and allows flexible reactions to unforeseen circumstances. In the event of supply shortages or other bottleneck situations, for instance, the low-energy standby mode is activated.

Related News

Latest News Texprocess 2015

2015-04-14

More News from Veit GmbH & Co.

2016-03-06

Latest News

2025-10-02