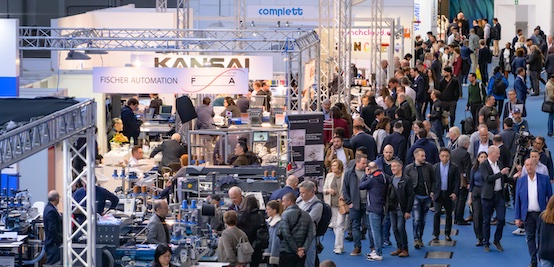

#Texprocess 2024

VEIT Group presents product highlights and innovations at Texprocess 2024

In compliance with the company slogan "Pressing for Excellence", the VEIT GROUP has invested a lot of time in the further development of products and worked on new, innovative solutions over the last two years. The motto of the fair is "LOVEIT". "LOVEIT stands for the passion we put into the development of our products, the love of perfection and the dedication to our customers".

This motto and the product presentation in Hall 8.0, booth A28 include the following innovations and product highlights:

Shirt Finisher SF 27: Innovative shirt finisher with sustainable heat recovery system

The development of the new SF 27 Shirt Finisher was carried out with the involvement of fluidic engineers and specialists in the field of emission optimization. With the new model, VEIT has succeeded in further improving both the quality of the finished shirt and the functionality and ergonomics of the Shirt Finisher.

This high-performance shirt finisher is particularly suitable for shirt and blouse production.

VEIT GmbH pursues the philosophy of offering its customers sustainable solutions. A central component of this philosophy is the new SF 27 shirt finisher, which also strives to reduce emissions (energy, temperature and noise) to a minimum.

The SF 27's heat recovery system, equipped with state-of-the-art heat exchanger technology, creates a pleasant working environment. It absorbs radiant heat energy and transfers it to the dry extracted air, which also allows the humid exhaust air to be discharged to the outside.

The integration of the technical components means that the appliance's footprint remains unchanged. The optimized energy recovery not only contributes to a positive working experience, but also reduces the ecological footprint. Our aim is to achieve fast, economical drying times and a high-quality finish with minimal energy consumption.

With the SF 27, VEIT significantly reduces energy consumption, increases the quality of the finished shirts and optimizes the ergonomics of the shirt finisher. For the customer, this means: 80 perfectly finished shirts per hour with only 20 kg/h steam consumption!

Compact Finisher CF 20: Space-saving thanks to its compatible size

The CF 20 compact finisher offers a perfect solution for businesses with limited space and lower production volumes, without compromising on quality. Customers benefit from the automated process, not least because it saves a lot of time. The new CF 20 is very easy to integrate into existing processes and ensures efficient workflows. The synchronized process enables a fantastic finish result.

Pants Finisher PF 50: The all-rounder with Industry 4.0 connectivity

The PF 50 Pants Finisher is an all-rounder in the textile industry that ensures perfect finishing results thanks to its Industry 4.0 connection and state-of-the-art control technology, while also offering process data acquisition for quality assurance in one.

The PF 50 is equipped with state-of-the-art control technology that allows users to view and set all program parameters at a glance. This precise control enables a flawless finish and optimizes the manufacturing process.

An outstanding feature of the PF 50 Pants Finisher is its Stretch Control function, which enables sensitive adjustment for waist width and leg length. This function ensures a tailored fit for every pair of trousers and offers the user maximum flexibility.

The waistband tensioning unit of the PF 50 Pants Finisher enables precise and repeatable adjustment of the waistband tensioning force. The 2-dimensional waistband tension extends the size range, resulting in an even more precise fit.

FM (Fusing Machine) or LM (Laminating Machine): New machine type with an improved energy management concept, improved ergonomics, and expanded digital possibilities

The new machine type has been optimized in many areas. These include a revised machine design to ensure improved ergonomics and easier access to maintenance points.

A modified insulation concept leads to lower energy consumption and reduces the machine's wasted energy in the form of heat. To meet future requirements, the control panel has been significantly improved and interfaces expanded.

"One major goal was to increase the vertical range of manufacture for the Landsberg am Lech site," reveals Sascha Oehl, Director Product & Innovation. "All sheet metal parts are now manufactured on site".

WR 16 Winding and Rewinding Device for für FM / LM: The perfect addition for VEIT laminating or fusing machines

This innovative solution enables the effortless unwinding of individual textile bales, which are then automatically rewound in the joined state.

The WR 16 offers numerous advantages, including perimeter controlled technology for tension-free material handling and easy roll changes. All machine movements are carried out electrically, ensuring smooth and efficient operation. The entire process flow and speed control is handled by the machine controller, allowing for precise control and adjustment.

This versatile winding and rewinding device not only enables full fusing, laminating and pre-shrinking, but also features optical web edge detection and an integrated scutting device for maximum efficiency and precision. With a roll width of up to 1600 mm and a variety of versions, the WR 16 offers the flexibility to meet the requirements of a wide range of production environments.

Universal Finisher UF 30: The all-rounder on 0.5 m²

With the new UF 30 model, customers gain versatility in finishing for their business. It convinces with the finishing process from 10 seconds depending on the type of garment and application: T-shirts, polos, blouses, dresses, skirts, blousons, jackets, coats and much more. User-friendliness is demonstrated by the adjustable bust height for ergonomic loading and unloading.

The product highlights are complemented by the VEIT Varioset ironing station. The Varioset ironing station series is characterized by its excellent suction and blowing performance at a very low noise level.