Texprocess 2015

Texprocess is the answer to new demands in production competence

Shortly, to be exact from the 4th to the 7th of May, the Texprocess is to take place for the third time in the trade fair city of Frankfurt, Germany. As in previous years, the Texprocess will be happening at the same time as the Techtextil exhibition in a two-year cycle. The international leading trade fair for processing textile and flexible materials will be presenting the most modern technology for design, cutting, IT, sewing, bonding, stitching, refining, finishing and logistics.

Both previous Texprocess events can be considered a success. Even more so when one considers that one of the main reasons that the Texprocess was established four years ago as a new trade fair for the clothing and leather industry was the dwindling number of visitors to the previously existing trade fair. Primarily it was the absence of international visitors that exhibitors complained about. All that can be said retrospectively in this case to the address of the Garment and Leather Technology Association of the Federation of German Machine and Plant Manufacturers (Verband Deutscher Maschinen und Anlagenbau - VDMA) is: the right decision was made - the result is that the Texprocess has become, following two successful events, a well-established appointment in the clothing sector calendar. One of the reasons for the huge success is surely to be attributed to the coupling with the Techtextil, which gives visitors to the events the opportunity to discover a variety of topics in a manageable amount of time. Another reason is clearly the perfect organisation by the Frankfurt trade fair staff, which guarantees that everything runs smoothly and always brings with it fresh ideas to the trade fair with a varied supporting programme.

Let’s take a look at a few figures. 330 exhibitors (+4% on 2011) presented their products and solutions at the Texprocess 2013 and covered the entire value-added chain. Their offering reached over 12,100 direct visitors (+16% on 2011) from 98 countries, as well as 8,100 from the parallel Techtextil. The high level of internationality of the Texprocess must also be mentioned, with over 60% of the exhibitors, and more than 50% of visitors coming from abroad. In a survey of the visitors, 94% said that they were happy or very happy with their visit to the Texprocess.

As we already mentioned in our report concerning the Techtextil, we would like to inform about a few of the key points and exhibition the highlights in more detail. In the event that you are still undecided about a visit, a few pieces of background information will certainly be useful in making your decision.

The product offering of the Texprocess extends across all steps of value added textiles from fabrics to clothing, and includes design, IT and cutting, as well as sewing, bonding, stitching and knitting, all the way to finishing, textile printing and logistics.

The hall concept, developed for the Texprocess 2013 and which proved to be very successful, will be kept for the Texprocess 2015: In hall 4, visitors will find a number of innovations from the areas design, IT, CAD/CAM, cutting and the IT@Texprocess special area. In hall 5, exhibitors will present innovative machines and accessories for sewing, stitching and bonding. The programme is rounded off in hall 6 with embroidery techniques, finishing and textile logistics. The “Source it” area, a special area in 2013, will not be a special area in 2015, but will rather be integrated as a product group of Texprocess as well as a topic of the Texprocess forum.

Four months prior to the start of the Texprocess, 95% of the previous exhibition space had been rented. Two years ago, at the same point in time, it was only 70% - according to the Messe Frankfurt. The Texprocess is growing in a number of directions: Textile machines, sewing, bonding and fastening technology, automatic control engineering, textile finishing, cutting and automatic control engineering as well as product processing and finishing are all gaining importance.

Two pieces of news should be of particular interest for the clothing industry and relation producers. On the one hand, growth of more than 23%, as quoted by the VDMA German Garment and Leather Technology Association, of the German and European clothing and leather technology sector in the period between January and October 2014 must wake up the whole sector to pay attention. The question is often asked, “who has invested what and to what end?”. After all, a significant increase in volume generally heralds a paradigm shift. A factor which could spontaneously force itself into considerations, is the investment in more “sustainability”, that is to say the energy-saving, environmentally-friendly systems. The same can be said for investment in IT, namely in CAD, 3D, PLM and Cloud software systems, which make a global collaboration possible through significantly optimised processes

This is exactly the way Elgar Straub sees it, Managing Director of the VDMA German Garment and Leather Technology Association. “The integration of industry 4.0, and with it the digital interweaving of design, processing and logistics of clothing and textiles, remains decisive in competition. Sustainable production also continues to play a significant role, above all else under the background of increasing state regulation,” he says.

Sustainability is developing from a “nice-to-have” more and more to a “must-have”, in order to keep up with the competition in future. Many retailers and brands have issued very high targets in the last two years in terms of their own sustainable development and have to set a tremendous pace to keep their promises. The fashion giant H&M, for example, publishing a a CSR report already since 2002, investigated all challenges along its textile value added chain and evaluated its influence on the sustainable development. The results were published in the 2013 Sustainability Report of H&M: Clothing production only has a minimal impact on environmental pollution (6%) and water pollution (1%), and therefore a minimal impact on generational equity. However, clothing production still has the greatest effect on the working conditions of the textile workers and in turn social equity around the world.

“Choose and reward responsible partners” is one of the seven commitments which H&M has adopted. This responsibility also needs next to labour protection and fair wages a modern equipped workplace for employees, which helps to compensate higher hourly rates through increased productivity, too.

Especially those who use out-dated systems as profitable cash cows could encounter problems with their “business model” in this way; brands and retailers are conducting more and more audits at textile companies. At H&M, for example, this inspection must be carried out every year, the sustainability efforts of suppliers and their factories must be inspected and new partners must be inspected in detail, before production orders can be placed. For this reason it is all the more important for clothing companies that they are aware of the standard of technology, even if it is only to be able to categorise their own production competence. In this respect, the Texprocess is a welcome parade of performance.

Production competence is also being increasingly influenced by IT and networking. Frequent changeovers and ultra-short “time-to-markets” of fashion show trends to finished clothing on the shelves demand structured processes which must also be supplemented by the best technology available.

“3D is a key competitive factor for clothing companies who want to visualise their products in a top-quality way and to integrate their digital models optimally into their business models,” said Human Solutions/Assyst Managing Director Dr. Andreas Seidl in an interview with TexData, shortly after the Texprocess 2013, and specified CAD-Management, cooperation, automation and systems integration as the new tasks of the CAD systems of the future. Now, at the Texprocess 2015, Human Solutions/Assyst is taking a step into this future under the motto “One process for fashion,” and is presenting the interaction of their solutions for the whole process chain.

Even if IT has been integrated into the processes of the clothing and fashion industries for quite a number of years, and 3D is no longer to be viewed as new technology, the dynamics in development in the software and process control areas continue to remain impressive. Many of the systems from leading manufactures have been redeveloped, improved and further integrated in the last two years.

An example of this is that of Gerber Technologies, a further market leader, who, in the spring of October 2014, announced a new version of its widely popular Software AccuMark. AccuMark 10 comes with a completely integrated 3D solution for the design of clothing and type designs. “AccuMark 10 will change the idea of type designs in a big way. This technology will bring us to a new level of efficiency and speed in the design process,” says Mary McFadden, Director, CAD Product Management at Gerber Technology.

Yunique Solutions, a business division of Gerber Technologies, shows just how important Cloud-solutions have become for clothing production. At the end of March, the company released a test drive for their PLM solution “YuniquePLM™ In The Cloud” specially developed for the fashion industry. The solution is available as an Amazon Web Service (AWS) and companies can register and test the functionality within a matter of minutes.

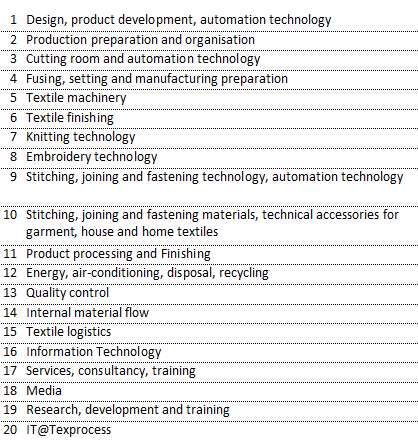

This few examples give an impression that visitors can expect a lot of the IT on show at the Texprocess. And it is likely that there will be a variety of innovations also in the other 19 product groups (table 1), such as “cutting and automation technology” or “sewing, bonding and fastening technology”.

Table 1: Product Groups of Texprocess

It is the power of innovation which makes the trade fair so impressive and is the main reason that many of the textile people travel to Frankfurt. As in previous years, the best innovations will be awarded with the Texprocess Innovation Award. It does not play a role whether the company is a global market leader or a start up. The award is even open to non-exhibitors. The only thing that counts for the award is that it must be an outstanding development, the product must be new - that is to say it may only have been available on the market for no longer than two years, and that the market launch is imminent. Furthermore, the product may not have won any other awards.

Pic: Presentation of Innovation at Texprocess

Alongside innovative exhibits, visitors can expect up-to-date presentations at the Texprocess Forum. The following topics will be discussed: Sourcing, country presentations, sustainability and social standards, entry to the Chinese Market, trademark protection, customs guidelines, new technologies, logistics, 3D, space management, PDM/PLM and RFID. We find the topic “entry into the Chinese market” particularly interesting as there are significant opportunities here for European and before anyone else German clothes producers, as recently announced by Germany Trade & Invest (GTI). A particular popularity of western clothing products stood in stark contrast to a particularly low import quota.

Anyone who now thinks that everything does not yet have any “Sex Appeal”, we would like to stress to him that the production basis for the clothing of tomorrow is going to be presented and that through technology the changes effected for fashion conscious consumers will more than likely be very sexy. The organisers have come up with a brand new idea to underpin this: The first “Innovative Apparel Show” will be a “live-on-stage presentation” of innovative materials and functional clothing textiles designed by renowned textile research institutions and universities.

The “Innovative Apparel Show” also forms a bridge to the Texchtextil: materials for the technical textiles and non-wovens are integrated into the “fashion show” which makes it different from classical catwalk events. This is a promising new idea for the tried and tested recipe for success for the double-bill event comprised of the Texprocess and the Techtextil.

It’ s clear: organisation, innovation and dialogue makes Texprocess 2015 once again an event that will satisfy nearly all exhibitors and visitors. Oh, do you remember? We said that there were two important pieces of news for the clothing sector.

The second piece to pay attention to is to do with growth and the clothing market itself. The global population continues to increase and the buying power of the growing middle class is increasing in the emerging markets. This also entails that the desire for fashionable clothing is growing. According to information given by the WTO, clothing exports increased by 9% to US$ 460 billion in 2013. Of this amount, US$ 118 billion were accounted for by the 28 member states of the EU. While the amount of clothing being produced continues to grow in traditional producing countries, such as China, Vietnam and Bangladesh, other countries such as Thailand find themselves in the midst of an upheaval; the same is true of new markets such as in Ethiopia and Myanmar.

Well, we’ve named quite a few reasons why a visit to the Texprocess is certainly worth it. At least for our part we are looking forward to the variety of innovations and the highly interesting events and talks. We will keep you updated with information via the TexData Infoletter up until the beginning of the trade fair. And in issue 2 / 2015 of the TexData magazine you will find a comprehensive report and all the information we have gathered for you about Texprocess.