#Spinning

Competing in the DTY Specialties Market

The SSM single-position machine concept for various applications

Polyester DTY (Drawn Textured Yarn) was first produced in the 1960s and has since become a commodity yarn. However, over time, polyester yarns have evolved to be used in a variety of specialty yarns, ranging from coarse denier per filament (dpf) to micro-filament and even super-micro-filament yarns. These yarns can be used to produce fabrics with a very soft touch and a light weight.

Filaments with different cross-sectional shapes improve perspiration evaporation or provide the fabric with a distinctive luster. Another specialty is achieved by encapsulating functional chemicals directly into the polymer to create fabrics with additional characteristics such as anti-bacterial properties to eliminate odors or using infrared body emissions to increase body temperature. Furthermore, an increase in dope dyed POY (Partially Oriented Yarn) brings advantages for color fastness and in terms of environmental friendliness, as no subsequent dyeing is required.

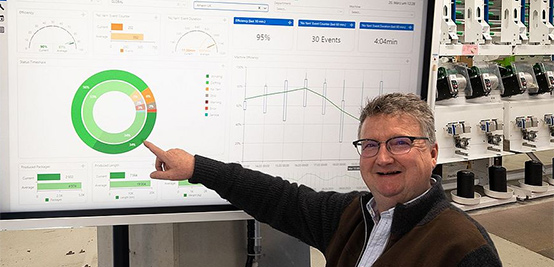

All these specialties are the new standard in DTY and bring new challenges for texturizers, e.g., the need for more flexibility in production, as more specialties mean more but smaller lots to be produced. Thanks to the DP5-T, SSM is already in a strong leading position in the air-texturing market; now it is solidifying this position by launching the most flexible false-twist texturing machine, the DP5-FT (Fig. 1).

A single-position machine concept for full flexibility

An entire DP5-FT machine with 40 positions can be set up with up to 40 different recipes. Every position is almost a standalone false twist (FT) machine with its own heater, control board and is furthermore equipped with individually driven, programmable motors.

There is no need to invest in an equivalent laboratory machine. Customers can simply dedicate one or multiple positions of the DP5-FT to trials and sampling. The position(s) can be reassigned back to normal production later to maximize efficiency and reduce sampling costs.

The individual position concept also brings advantages in terms of power consumption and production efficiency. Unlike shaft machines, the power consumption of a position is reduced when it is not in use, as all affected motors are stopped. Moreover, a power-saving function can be activated after a certain amount of idle time has elapsed to reduce the temperature of the heater and godet – maximizing the potential savings. On a running shaft machine, it is also common to find positions without yarn, because a wrap after a yarn break cannot safely be removed while running, or because a faulty position is awaiting the next machine stop. There are no such limitations with an individual position machine concept because each position can be stopped individually and serviced immediately, resulting in higher machine efficiency.

Last but not least, the DP5-FT is the first choice for manufacturers whose top priority is personal safety, as the individual position concept allows the use of much smaller motors, limiting the risk of severe injuries to operators.

Flexibility to increase production capacity

The high flexibility of the DP5-FT is reflected in the minimum available number of five positions only, making it the perfect solution for customers entering the DTY business. It enables full flexibility in terms of lot sizes, types and counts of DTY yarns as well as better control of the supply chain. If a customer later wants to increase the DTY production capacity, the machine can be extended to include up to 40 positions without changing the head stock and using the same machine terminal.

Full control and inspection without stopping the machine

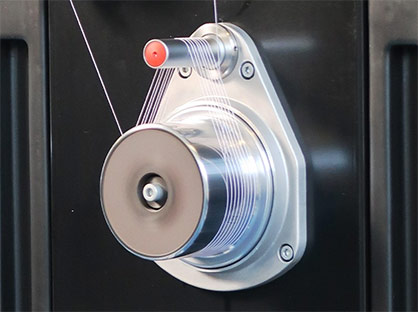

A unique feature of SSM texturing machines is the heated godet (Fig. 2) to heat-set the DTY yarn and achieve the required elasticity. This is state-of-the-art in the production of polyester DTY yarns. Due to their length, tube heaters on competitors’ machines are installed at the rear of the machine or underneath the catwalk. Therefore, operators can’t inspect them during production or remove the internal tube periodically for cleaning. On SSM texturing machines, the heat-setting godet is located at the front of the machine, enabling full control and inspection of the entire yarn path at any time without stopping the machine. Instead of using a tube heater with a predefined length, using a godet also allows operators to influence the duration of the heat setting process by increasing or decreasing the number of wraps around the godets.

With this modern machine concept, SSM offers texturizers a proper tool to stay at the forefront of the competitive DTY specialty market.