#Spinning

Digitization to unlock performance and growth potential

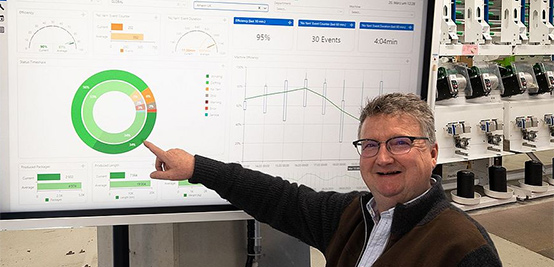

Textile manufacturing is becoming more and more datadriven. Key players in the industry are embracing the digital transformation to enable a more profitable and sustainable growth. Nema, SSM digital suite, gathers information leading to data-based decisions, less downtime, higher productivity and better quality. It also helps customers to quickly and easily duplicate success to any connected machines, anywhere.

Early detection, quick action, lower downtime

Timely detection of any fault during the production process is difficult and often comes at too late a stage. Nema tracks machine health-related data such as machine and position errors, warnings, etc. in near real-time, and transmits these data to a dashboard, thus providing a global overview. The system alerts about any deviation for an early detection of abnormalities. Data-based decisions can be made in a timely matter, thus limiting expensive downtime, costs, and loss of revenue.

Quickly duplicating success to other plants

Tracking key performance indicators, Nema enables customers to identify the conditions of the best performing machines. These conditions can then easily be replicated to ensure a high production level, throughout the entire machine fleet.

5% higher efficiency at AMANN

AMANN is one of the leading international manufacturers of high-quality sewing threads, embroidery threads and smart yarns for technical textiles. Being innovators in its field, the company is one of the first to use Nema to oversee the performance of its eight production sites. After only three months, AMANN optimized its manufacturing workflows, resulting in more than 5% higher efficiency on average. Real-time data is becoming a standard in the textile industry. Through near real-time monitoring and a smart utilization of production data, Nema gives the right insights, at the right time to unlock the full potential of the entire winding machine fleet.