#Research & Development

DITF send a signal for climate protection

The state government wants to organize the state administration climate-neutral (net greenhouse gas neutral) by 2030. In addition to state-owned buildings, the buildings of business-related research institutions are also taken into account. Accordingly, the DITF want to significantly reduce their energy and heating requirements while at the same time generating their own energy from renewable energy sources. An important component of this concept is the new photovoltaic system.

After a welcome address by DITF Chairman Professor Michael R. Buchmeiser, the mayor of the municipality of Denkendorf, Ralf Barth, and Permanent Secretary Michael Kleiner from the Baden-Württemberg Ministry of Economic Affairs, Labor, and Tourism gave welcoming speeches.

“The efforts of the DITF perfectly complement the extensive activities of the municipality with the aim of actively shaping the energy transition and climate change while saving money at the same time,” emphasized Ralf Barth.

“The coalition agreement for Baden-Württemberg announces the creation of climate-neutral facilities for business-oriented research, thereby taking on a pioneering role nationwide. With €1.4 million in funding for the new photovoltaic system, we want to make a decisive contribution to this,” said Michael Kleiner, underscoring the state's commitment. “With today's commissioning, the German Institutes of Textile and Fiber Research are taking another important step toward climate neutrality – and underlining their role model function for sustainable and efficient research.”

The DITF are committed to continuously reduce their ecological footprint. Ecological sustainability involves conserving resources and energy as well as avoiding or reducing CO2 emissions. To this end, a transformation concept was drawn up in 2024 that includes climate-neutral energy generation and efficient thermal insulation of all buildings, as well as many other measures. For example, sustainable mobility for employees is also promoted with charging stations for electric vehicles, bicycle racks with charging facilities, and bicycle leasing options.

After the solar power system was put into operation, guests were able to experience for themselves that sustainability also plays a central role in DITF's research. State-of-the-art analysis and testing methods are used in the development of new textile materials, process technologies, and production methods to examine and optimize the properties and performance of the materials. The DITF have currently launched two major research projects with a total project volume of over €4.2 million. These projects focus on the recycling of high-performance fibers such as carbon and glass fibers for demanding applications and the recycling of classic textile waste into high-quality yarns.

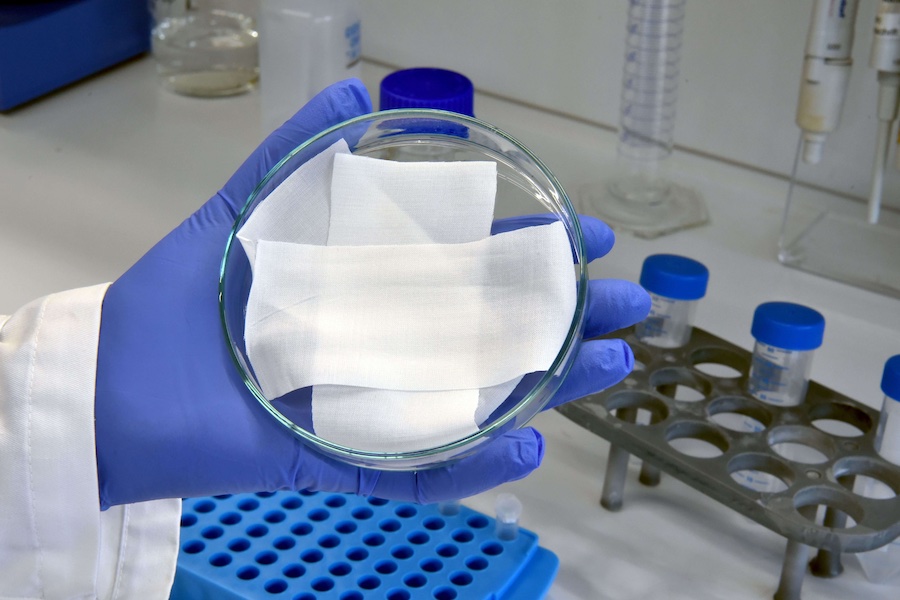

At several stations, scientists presented fibers and composite materials made from renewable raw materials. One interesting component for high-performance applications, for example, is lignin, a waste product from the paper industry that can be used to produce carbon fibers, environmentally friendly coatings, and composite materials.

In order to coordinate the sustainable transformation of the Denkendorf research center, a staff position reporting directly to the Executive Board, the Chief Sustainability Officer (CSO), was established in 2024. PD Dr.-Ing. Thomas Stegmaier, CSO, develops solutions to reduce the DITF's energy and resource consumption, promote renewable energies, and implement efficient energy use. He also acts as a driving force to advance research on sustainability issues.