#Research & Development

Panty liners prevent bacterial vaginosis

As part of a BW Sprint project, the German Institutes of Textile and Fiber Research Denkendorf (DITF) have laid the basis for the development of a panty liner that supports the health of the vaginal environment and can prevent bacterial vaginosis.

The microbiome is the totality of all microorganisms such as bacteria, viruses and fungi on and in the human body. It is of central importance for the immune system. If the microbiome is out of balance, pathogens can spread more quickly. A disorder of the vaginal flora often results in a reduction of lactic acid bacteria present in a healthy microbiome, resulting in less lactic acid (lactate) being released and a significant increase in the pH value in the vagina. This increases the risk of bacterial vaginosis.

There is currently no satisfactory prevention or treatment for bacterial vaginosis. Treatment with antibiotics in accordance with medical guidelines leads to a relapse rate of around 50 percent. This places a heavy physical and, in most cases, psychological stress on the women affected.

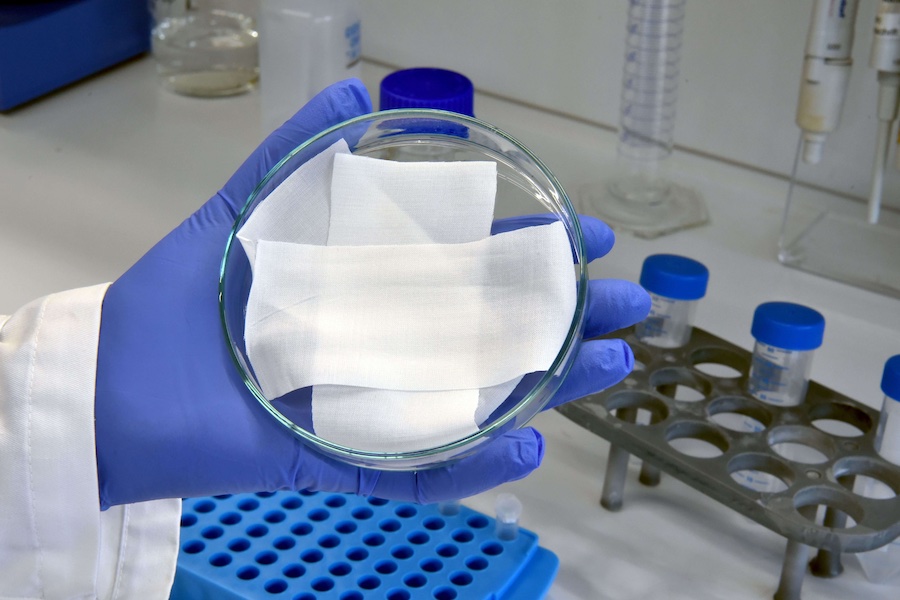

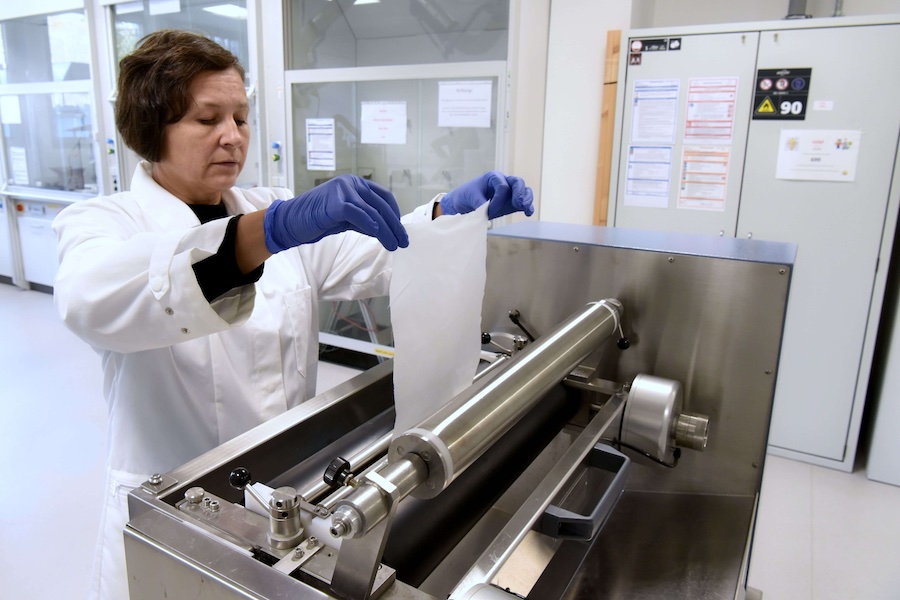

At the DITF, a research team has laid the basis for the development of a panty liner loaded with lactide. Lactide is the cyclic diester of lactic acid. It can be incorporated into a textile carrier in various ways. An effective method is to spin a solution of polymer and active substance into fibers. The application of a coating loaded with active substance to a cellulose textile was also tested at the DITF. When the panty liner is worn, the lactide released in the physiological environment turns into lactic acid (lactate). The pH value in the vaginal environment can be lowered to a “healthy”, slightly acidic level. This can make a decisive contribution to preventing bacterial vaginosis and avoiding its recurrence.

The release rate of the active substance must take into account the actual duration of use of panty liners. To achieve this, an active substance had to be found that is released within a few minutes for a few hours in a temperature- and moisture-controlled manner. Another requirement is to use resource-saving and environmentally friendly materials.

Initial tests with simulated vaginal fluid showed that lactide-loaded fibers and coated fabrics can reduce the pH value from an “unhealthy” value of over 4.6 to a “healthy” value of 3.8 within a short period of time.

Further research projects will continue to pursue this promising approach toward a preventively effective panty liner. To this end, a realistic vaginal test model will be developed to further optimize the textile materials loaded with active substances. The focus will be on body and environmental compatibility.