#Research & Development

Compact solution with great effect

Sound absorbers for optimal acoustics

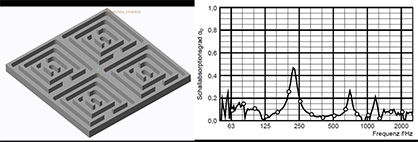

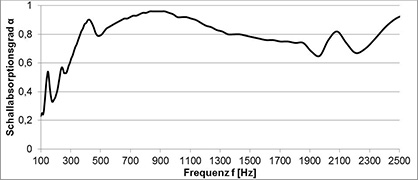

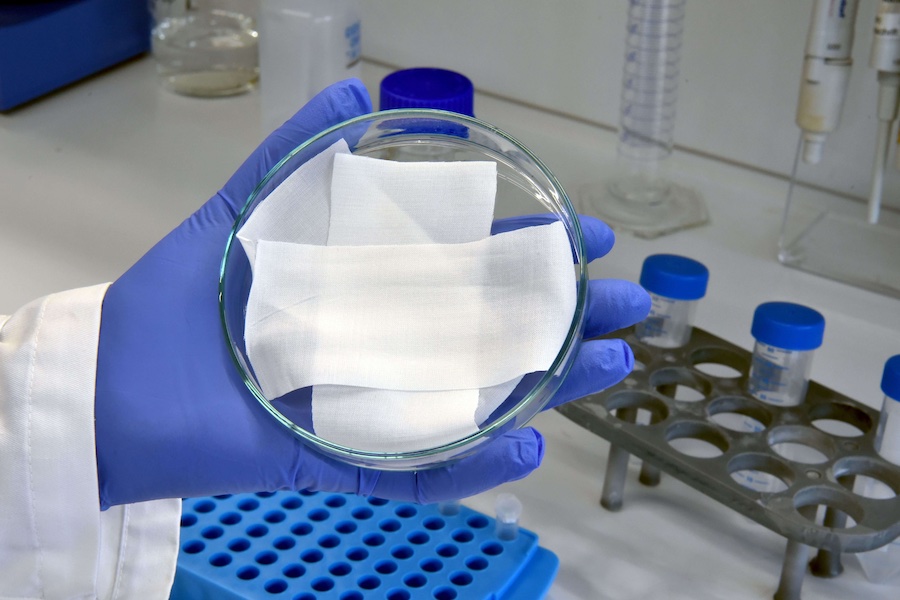

A textile is responsible for the medium and high frequencies. The low frequencies are absorbed by a novel cavern structure. The cavities are arranged in such a way that they act like classic Helmholtz resonators despite their significantly smaller depth and volume. The scientists were able to demonstrate that these two principles not only complement, but also reinforce each other. The result is an optimal sound experience.

Since the compact component is available in various sizes and colors, it also fits well in open-plan offices or in living spaces located along busy roads. "It is the car traffic in particular that causes the deep tones that cannot be filtered out by many conventional sound absorbers", explains Karsten Neuwerk, research associate at the DITF.

The sound absorbers developed in the research project are sustainable, and not only because they are manufactured in an environmentally-friendly way. In its Agenda 2030, the United Nations has set 17 sustainability goals, including health and well-being. Noise protection plays an important role in so-called "psychoacoustics". "With our research work, we not only set technical standards, but also ensure a pleasant auditory experience that promotes well-being with optimal volume and sound modulation," summarizes Dr. Michael Haupt. He heads the e-textiles, automation and acoustics division at the DITF.

The results of the research project are several demonstrators of which effectiveness could be proved by measurement.

The absorbers will be available on the market before the end of this year for architects, sound engineers and private consumers.