#Nonwovens / Technical Textiles

Wolf PVG trusts in meltblown technology from Oerlikon Nonwoven

With the beginning of the corona pandemic and the shortage of protective masks that ensued, Wolf PVG GmbH & Co. KG, a wholly-owned subsidiary of the Melitta Group, switched part of its production capacities to nonwoven mask fabric production. As a highly specialised system supplier for everything to do with vacuum cleaners and industrial filter technology, the company from East Westphalia can fall back on its extensive know-how and many years of experience.

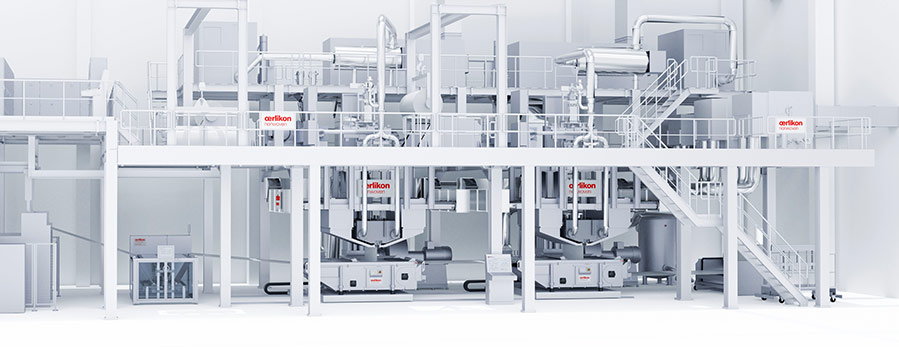

With the meltblown plant from Oerlikon Nonwoven, Wolf PVG is further expanding its production capacities. The plant, with its two beams and the ecuTEC+ electro charging unit, is optimally designed for the production of face mask material. The plant is also ideal for the production of other filtration nonwovens.

“A decisive point for investing in a plant from Oerlikon Nonwoven was the flexibility of the plant in relation to the possible product portfolio and the competence of the manufacturer,” explains Markus Seele, COO of Wolf PVG. And Dr. Ingo Mählmann, Senior Vice President Sales & Marketing Oerlikon Nonwoven, adds: "Thanks to the numerous setting options for the electrostatic charge provided by the ecuTEC+, the optimum loading status can be set depending on the filter application."

ecuTEC+ electro charging unit from Oerlikon Nonwoven complements filter nonwoven plants

The meltblown technology from Oerlikon Nonwoven is considered the most technically efficient process for the production of highly effective filter media from plastic fibres. The ecuTEC+ electro charging unit also makes a significant contribution to this. With the patented process, spunbond and meltblown materials can be charged electrostatically and thus the filter performance can be significantly increased. In this way even the smallest particles are safely filtered. Nonwoven manufacturers are thereby largely free to choose and can set the optimal charging method and intensity for their filter application.