#Knitting & Hosiery

SHIMA SEIKI constructs new WHOLEGARMENT factory

- Natural daylight in combination with inverter-controlled variable lighting and motion sensors achieves even lighting conditions throughout the factory, while conserving electrical consumption by 50 per cent.

- 1,000 solar panels produce a total output of 220kW. This addition brings SHIMA SEIKI's total solar electric generation capacity to 1,550kW—one of the highest outputs for a Japanese private enterprise.

- Inverter-controlled air conditioning conserves energy by 35 per cent.

- Truss-architecture allows thinner pillars to be spaced farther apart, resulting in a more spacious work environment using less construction materials.

- Improved foundation techniques replace conventional post-and-beam structure for increased earthquake resistance.

- Increased floor height, floodgate doors and retaining walls minimize tsunami damage.

- A 650 square meter outdoor architectural textile canopy provides improved shipping conditions in foul weather.

- All trees uprooted during construction of the new factory were transplanted to other locations on company grounds. SHIMA SEIKI therefore maintains its green area ratio of 30 per cent of total company grounds, for which the company was awarded the Outstanding Green Development Factory Award from the Minister of Economy, Trade and Industry in 2007.

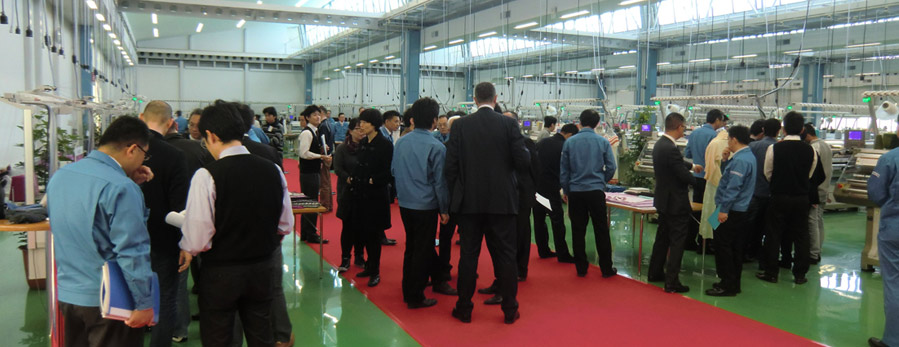

The factory has a total floorspace of over 2,400 square meters. It has a working capacity for 2,000 WHOLEGARMENT knitting machines annually, in anticipation of increased demand for the still-new technology that is continuously improving and steadily gaining a loyal following among SHIMA SEIKI customers. To commemorate the opening of the FA3 factory, SHIMA SEIKI held a private show featuring its latest line of WHOLEGARMENT knitting machines, using a portion of the factory floor as exhibit space.