#Knitting & Hosiery

SHIMA SEIKI announces partnership with Lonati

In the sock sector, it has been common practice to produce physical samples for design evaluation and production decisions. However, this method poses significant challenges, including wasted resources, labor intensity, high sampling and material costs, and long lead times that delay market launches. To address these inefficiencies, 3D Virtual Sampling has gained traction as a highly effective alternative, enabling design consideration without the need for physical samples. This approach facilitates rapid and efficient prototyping, helping companies lower costs, shorten development timelines, and reduce environmental impact. Furthermore, it enhances competitiveness by supporting the creation of products that are better aligned with market needs.

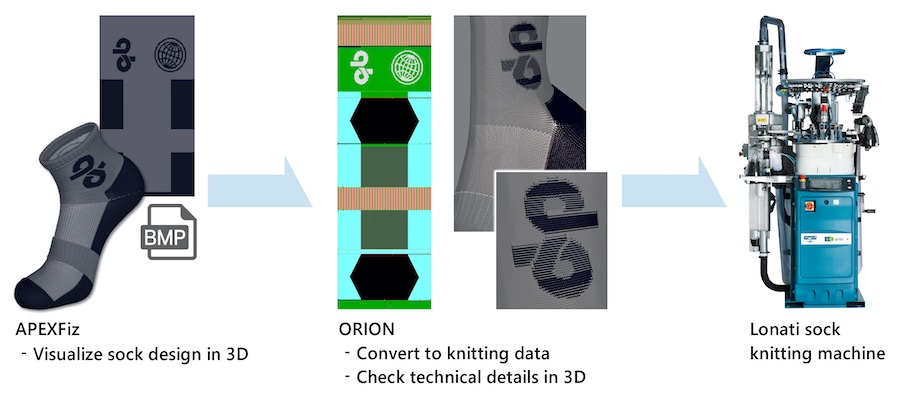

SHIMA SEIKI’s APEXFiz® software, already widely adopted and highly regarded within the sock industry, offers advanced 3D virtual sampling capabilities for knitted products. Designers using APEXFiz® can visualize sock designs in real time and receive immediate feedback, streamlining the development process. To further specialize in this sector, SHIMA SEIKI is also preparing to launch APEXFiz® Design-Sox, a dedicated sock design tool, in the near future.

On the technical side, Lonati’s ORION software, part of the UNLIMITEX® suite, provides comprehensive 3D verification of data throughout the programming-to-manufacturing workflow. This enables early detection and resolution of potential issues, ensuring higher production efficiency. Both APEXFiz® Design-Sox and ORION are scheduled for release in June 2025.

By integrating SHIMA SEIKI’s design strengths with Lonati’s programming expertise, the collaboration streamlines virtual sampling workflows from concept to production. This integrated digital process empowers companies to significantly reduce time-to-market while maintaining high product quality. The innovative workflow developed through the SHIMA SEIKI and Lonati partnership is poised to transform the sock industry, driving new business opportunities and offering a decisive competitive advantage.

canva-900-1-1-1.jpg)