#Knitting & Hosiery

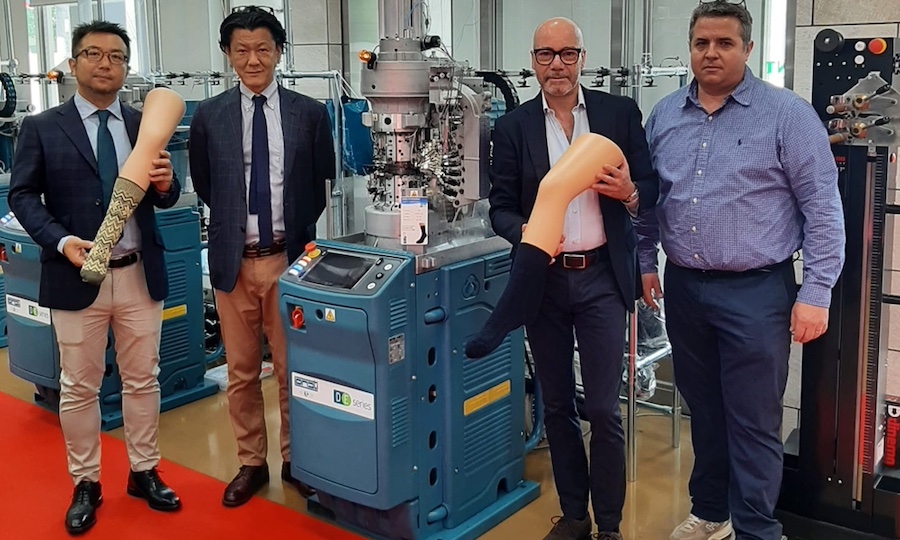

The newest Lonati DC88 DE 2H2 presented in Japan

The DC88 DE 2H2 is equipped with a single HF magnetic needle selection system, enabling flexible management of rib structures, links, and Jacquard patterns.

It also allows tuck stitch knitting on the lower cylinder on both feeds, improving fabric structure and performance. The brushless motor with variable reciprocation ensures precise movements, even during heel and toe knitting phases, while HTD belts with automatic tensioners extend the lifespan of the transmission system. Cylinder positioning is controlled by a magnetic encoder integrated directly into the lower cylinder, ensuring maximum precision throughout the entire production cycle.

For heel and toe knitting, the machine uses 4 selection points that replace pickers and droppers, allowing for a wide variety of patterns in both single and double feed modes.

The newly designed knitting head is engineered to reduce compressed air consumption and enhance fabric quality. Fabric width is adjusted electronically on each stitch cam via stepper motors, with real-time automatic correction. All machine functions are electronic, featuring active self-protection and self-diagnostic systems supported by backup batteries. The user interface consists of an intuitive graphic keyboard, which allows easy access to machine data, documentation, and troubleshooting messages. Article programming is performed via the ORION graphic software, compatible with Windows environment. The machine can be connected to a LAN network and integrated with Nautilus and Arcadia systems for real-time production data collection and monitoring.

The DC88 DE 2H2 will be available in 3”1/2, 3”3/4, and 4” diameters, with gauges ranging from 9 to 22.

80% less air consumption and increased productivity: tangible benefits of the DC88 DE 2H2

Recent consumption measurements show that the two-feeds heel version of the DC88 DE 2H2 requires an average of 17 NL of compressed air per sock (short size 11). In comparison, a traditional one-feed double-cylinder machine consumes approximately 110 NL per sock. This results in an 80% reduction in compressed air usage — a major advantage in terms of energy efficiency and lower operating costs.

Productivity: +61.5% compared to one-feed machines

In addition to reduced consumption, the DC88 DE 2H2 delivers significantly higher productivity.

When producing the same article over one hour, the following results were recorded:

• One-feed machine: 24.49 socks/hour

• DC88 DE 2H2 (two-feed heel): 39.56 socks/hour

This corresponds to a +61.5% productivity increase, made possible by the “Integral” technology, which enables heel and toe knitting in double feed mode even during reciprocated motion.