#Knitting & Hosiery

Benefit from the growing trend for sun protection

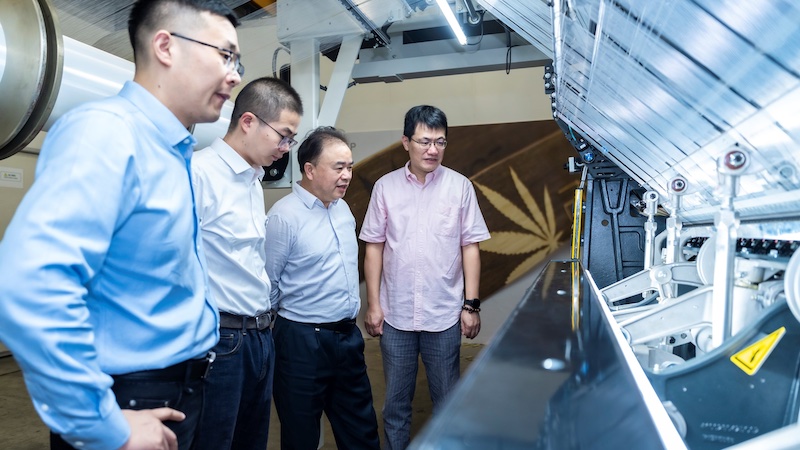

“Our E44 tricot machine and its products for the Outdoor sector underlined by its excellent UVA protection, to has peaked great interests among trade fair visitors,” says Xu Ying, Regional Product Owner Tricot machines at KARL MAYER (CHINA), during the trade fair.

This is not without reason. Temperatures are continuing to rise worldwide. In the summer of 2024, the Copernicus Climate Change Service registered the hottest June, August and day since records began. /1/

Effective sun protection during outdoor activities is therefore becoming increasingly important, especially for mountain sports. When hiking, climbing, or cycling, UV radiation increases by 2 to 3 % with every meter of altitude. At an altitude of 2,000 meters, there is already around 40 % more electromagnetic radiation. /2/

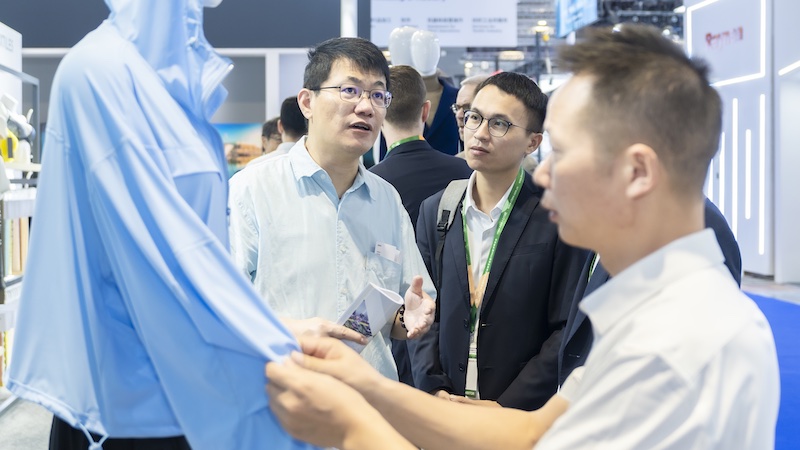

Sun protection products are therefore booming. In China, it is estimated that the market for UV protection products will grow from USD 10.3 billion in 2023 to USD 95.8 billion in 2026. Sun protection clothing in particular is extremely popular. On the e-commerce platform Taobao, sales of items from this segment for women amounted to a quarter of the total annual turnover for 2023 in May 2024. /3/ So it's no wonder that the HKS 2-S in E 44 with its extraordinary products was a top topic of the KARL MAYER presentation at ITMA ASIA + CITME 2024!

The smooth fabrics make outdoor fashion of a completely new quality possible. For outdoor activities in particular, the fine warp-knitted fabrics offer two decisive advantages compared to their circular knit counterparts with an almost identical fabric weight: their breathability is around 30% higher, making them significantly more comfortable to wear in terms of clothing physiology, and they absorb the sun's UV rays better. Due to the dense structure, the Ultraviolet Protection Factor (UPF) is more than twice as high. The lightweight textiles also show how a note of luxury, familiar from high-end clothing, can bring a touch of pep to the outdoor area. The soft fabrics are smooth, cool and silky against the skin, do not crease when worn and are highly resistant to pilling. And they ensure a carefree stay outdoors!

And they ensure a carefree stay outdoors!

KARL MAYER is looking forward to lively discussions about the development of new product ranges with its customers, but also with international sportswear brands. “We, Global Business Development at KARL MAYER, can push communication and collaboration with the brands. We offer a comprehensive range of expertise and equipment to support the successful development and implementation of innovations within Textiles," says Rachael Higgins, Vice President Global Business Development at KARL MAYER.

/1/https://www.zdf.de/nachrichten/panorama/klimawandel-sommer-wetter-hitze-hoechstwert-copernikus-100.html

/2/https://www.wetter.de/cms/uv-index-wo-und-wann-ist-die-sonnenbrandgefahr-besonders-hoch-5091724.html

/3/https://www.shine.cn/biz/economy/2408152993/