#Industry 4.0 / Digitalization

More speed and quality in the remote processing of support requests

A ticket to ride

The routing of the customer ticket can also be tracked through the KARL MAYER Customer Portal myKM.ON. Transparency ensures maximum planning reliability.

In future, a modern cloud connection will be used to access a machine remotely, offering maximum security and flexibility. Remote support requests can be made easily via the myKM.ON Customer Portal and therefore via any device in the customer's network. All that is needed is a Connectivity Package.

In addition, the new Remote Support Case makes the existing payment model more flexible, in line with a case rate.

Multi-level support for direct, seamless processing

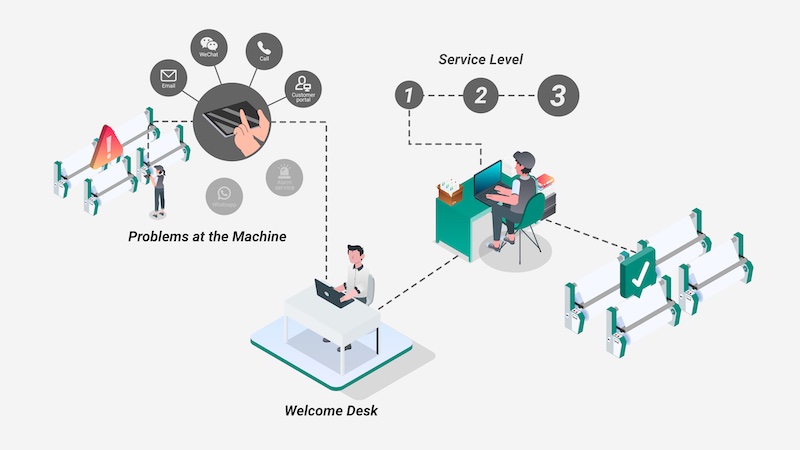

Service4you stands for a continuous customer journey with clear communication channels through a structured, seamless and transparent handling process for all remote support requests. It all starts with a ticket. The ticket for the rapid trip to troubleshooting is triggered by a global Welcome Desk after contact is made, for example by email or phone call. The staff of the Welcome Desk will be available to customers worldwide 20/6 in the near future. Anyone wishing to initiate their ticket directly can use myKM.ON and track all subsequent steps here.

The Welcome Desk ensures that the request is forwarded extremely quickly to the point of a new multi-level support that offers the most suitable expertise for processing.

Support level one consists of an international team qualified to solve simple problems. At the second support level, service technicians with expertise in the areas of mechanics, electrics, and networking crack the tougher nuts. Support level three offers the accumulated know-how of experienced specialists from the various divisions of the KARL MAYER GROUP. The multi-level, structured approach and the globalization of the organization optimize the processing of service requests.

"After completion of the project we will offer significantly more speed, availability and quality in solving problems than ever before”, says Adrian Graf, Project Manager at the KARL MAYER GROUP.

Remote Support Case offer for flexible payments

Just as simple and efficient as the remote support is its remuneration through the new Remote Support Case. In contrast to the previous machine-based contract system, application-based payment offers the customer maximum freedom. Once purchased in advance, customers can use the Remote Support Cases for their entire KARL MAYER warp knitting machine fleet at the site.

Warranty cases will continue to be processed quickly and competently without any Remote Support Cases.

To get assistance as quickly as possible, it is useful for customers to set up a case balance on their account, because: “We can only help after authorization by means of a Remote Support Case,” says Adrian Graf. Stockpiling is also attractively priced: Those who buy larger quantities also bene-fit from a quantity-based discount according to the motto "Pay four, get five". If a machine is con-nected to the KM.ON cloud, the customer also benefits from more favorable online cases for their entire fleet of warp knitting machines.

As well as flexible, the system of the Remote Support Cases is also fair. If the problem can be solved within 15 minutes, the Customer gets his Remote Support Case back in his contingent; if the remote support assignment ends unsuccessfully, the sum invested can be offset against the costs for the subsequent support work. The customer therefore bears no risk.

What's more, the performance is top of the line. With a Remote Support Case, the entire organization of the new multi-level support is available for several hours, with a validity period of 36 months.

Interesting offers make it easier to get started with the new concept. During the six-month introduction phase, every KARL MAYER warp knitting customer will receive three (3) Cases free of charge, which will be stored in their customer account.

The Remote Support Cases can in future be purchased via the WEBSHOP or alternatively directly from the Welcome Desk.

Faster and cheaper thanks to networking

Anyone who has at least one KARL MAYER warp knitting machine networked at their site with the KM.ON cloud via a Connectivity Package benefits from the Remote Support Case Online. Networking makes it possible to view into the connected machine directly from a distance in the event of service requests. This significantly speeds up problem solving. The customer also benefits from cost advantages for their entire warp knitting machine fleet, as a Remote Support Case Online is cheaper than its offline counterpart and also applies to non-networked machines.

Launch and further goals

Multi-level services, Welcome Desk and ticket system have been in pilot use with warp knitting customers in Germany, China and Hong Kong since June 2024. The rollout in further regions is planned for the end of December. Remote Support Case will be introduced at the beginning of October, initially for warp knitting machine parks in the service region of the KARL MAYER GROUP headquarters.

From October, the first warp preparation customers of KARL MAYER will also be able to take advantage of multi-level services, Welcome Desk and ticket system. STOLL and technical textiles customers will follow at the beginning of 2025.

Further steps are aimed at expanding the Service4you concept. From October, the Welcome Desk will not only be available in German, English and Chinese, but also in Italian and later in Turkish and Spanish.

In addition, the selection of contact channels with the Welcome Desk has already been expanded to include WeChat. WhatsApp is set to follow.

Further optimizations concern the concept itself. Adrian Graf welcomes feedback and suggestions for further developments via e-mail: ServiceFeedback@karlmayer.com