#Knitting & Hosiery

KARL MAYER at JEC: Multiaxial reinforced CFRP pultrusion profiles are picking up speed in the mobility sector

New lightweight construction applications and market opportunities with multiaxial non-crimp fabrics in the pultrusion process, JEC World, March 10-12, 2026 in Paris

The rapid speed of travel results in complex material stresses that require multiaxial reinforcement.

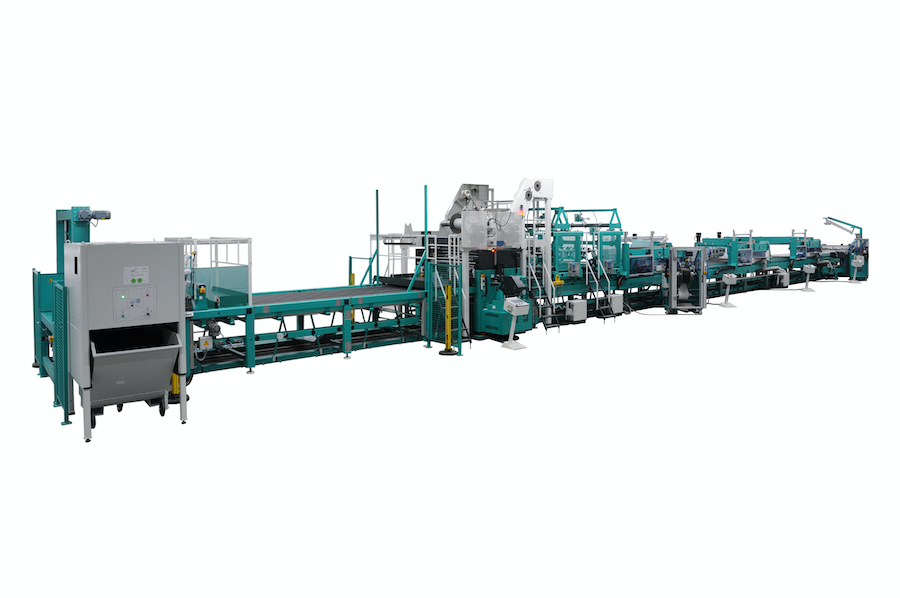

The textile-reinforced CFRP pultrusion profiles with a wall thickness of up to 25 mm are designed for multidimensional load cases. This makes them ideal for use in the highly stressed side walls of the lightweight railcar body in the CETROVO. There, they transfer longitudinal forces of up to 1,200 kN, absorb high bending loads, and contribute significantly to weight reduction – a total saving of 30% was achieved.

“Weight reduction is particularly important for underground and suburban railways. Due to frequent stop-and-go operation, mass inertia plays a key role in energy consumption compared to air resistance,” explains Prof. Dr.-Ing. Andreas Ulbricht, Managing Director of CG Rail GmbH.

Advanced process, additional reinforcement through multiaxial non-crimp fabric

CG Rail developed the CFRP profiles together with partners in Dresden on behalf of the Chinese rail vehicle manufacturer CRRC, specifically adapting the pultrusion process for this purpose. The modifications enable the production of innovative multi-chamber profiles with multiaxial continuous fiber reinforcement and lengths of over 20 m.

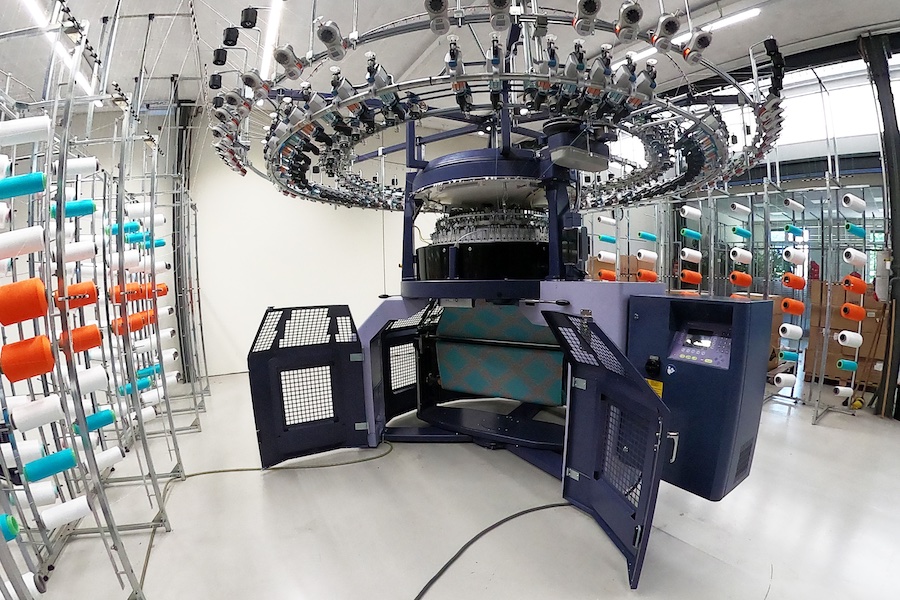

As additional reinforcement to conventional unidirectional longitudinal reinforcement, the CG Rail team primarily uses non-crimp fabrics from a COP MAX 5. The multiaxial warp knitting machine from KARL MAYER impresses with its high productivity, flexibility, and consistently high material quality. The reinforcement fibers can be inserted at angles of +/- 20° and with a pitch of 1°.

“The reinforcing fibers are precisely integrated into multiaxial non-crimp fabrics without any undulations. We can fully exploit their mechanical performance potential. In addition, they are better fixed in the textile surface than in comparable woven fabrics,” explains Prof. Dr.-Ing. Andreas Ulbricht.

From the laboratory to the rails

The first CFRP lightweight train celebrated its premiere at InnoTrans 2018 in Berlin. An advanced prototype was a highlight of the World Transport Convention in 2024. Since January 2025, the CETROVO 1.0 has been in service on Line 1 in the Chinese port city of Qingdao (Shandong Province).

CG Rail is already working on further projects. CFRP pultrusion profiles open up new perspectives, particularly in the commercial vehicle sector – for example, for ultra-light frame structures such as lattice frames for buses or semi-trailers for trucks. Experience shows that the lightweight potential compared to metal profiles is between 20 and 50%.

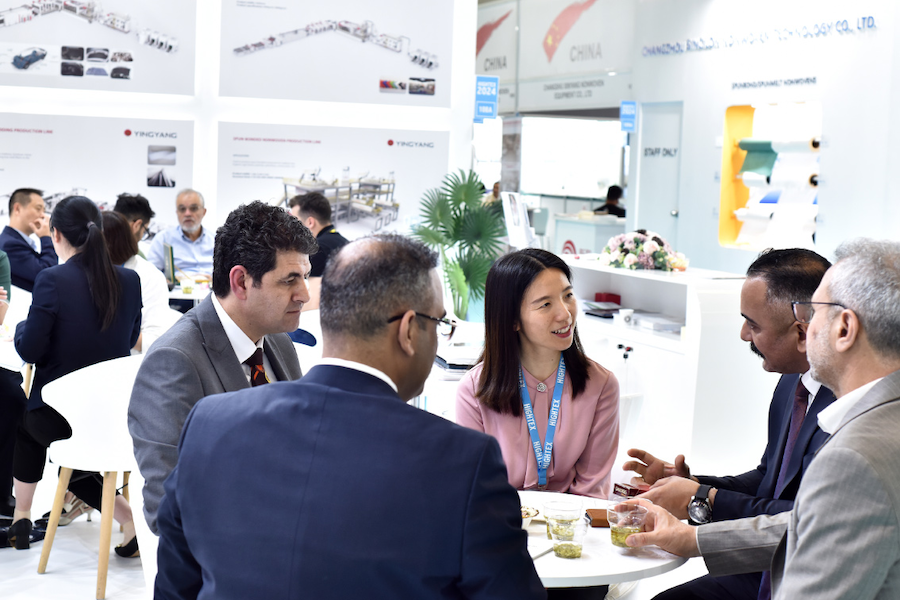

KARL MAYER Technical Textiles is presenting various CFRP pultrusion profiles at JEC and looks forward to discussing further new applications with trade visitors.

“Our composite machines also produce bi- and multiaxial non-crimp fabrics of glass, which are then further processed using the pultrusion method. The variety of materials and their laying angles offer exciting prospects for lightweight construction applications, which we would like to discuss with visitors at JEC,” says Kay Burkhardt, Product Manager at KARL MAYER Technical Textiles.

The rapid speed of travel results in complex material stresses that require multiaxial reinforcement.

The textile-reinforced CFRP pultrusion profiles with a wall thickness of up to 25 mm are designed for multidimensional load cases. This makes them ideal for use in the highly stressed side walls of the lightweight railcar body in the CETROVO. There, they transfer longitudinal forces of up to 1,200 kN, absorb high bending loads, and contribute significantly to weight reduction – a total saving of 30% was achieved.

“Weight reduction is particularly important for underground and suburban railways. Due to frequent stop-and-go operation, mass inertia plays a key role in energy consumption compared to air resistance,” explains Prof. Dr.-Ing. Andreas Ulbricht, Managing Director of CG Rail GmbH.

Advanced process, additional reinforcement through multiaxial non-crimp fabric

CG Rail developed the CFRP profiles together with partners in Dresden on behalf of the Chinese rail vehicle manufacturer CRRC, specifically adapting the pultrusion process for this purpose. The modifications enable the production of innovative multi-chamber profiles with multiaxial continuous fiber reinforcement and lengths of over 20 m.

As additional reinforcement to conventional unidirectional longitudinal reinforcement, the CG Rail team primarily uses non-crimp fabrics from a COP MAX 5. The multiaxial warp knitting machine from KARL MAYER impresses with its high productivity, flexibility, and consistently high material quality. The reinforcement fibers can be inserted at angles of +/- 20° and with a pitch of 1°.

“The reinforcing fibers are precisely integrated into multiaxial non-crimp fabrics without any undulations. We can fully exploit their mechanical performance potential. In addition, they are better fixed in the textile surface than in comparable woven fabrics,” explains Prof. Dr.-Ing. Andreas Ulbricht.

From the laboratory to the rails

The first CFRP lightweight train celebrated its premiere at InnoTrans 2018 in Berlin. An advanced prototype was a highlight of the World Transport Convention in 2024. Since January 2025, the CETROVO 1.0 has been in service on Line 1 in the Chinese port city of Qingdao (Shandong Province).

CG Rail is already working on further projects. CFRP pultrusion profiles open up new perspectives, particularly in the commercial vehicle sector – for example, for ultra-light frame structures such as lattice frames for buses or semi-trailers for trucks. Experience shows that the lightweight potential compared to metal profiles is between 20 and 50%.

KARL MAYER Technical Textiles is presenting various CFRP pultrusion profiles at JEC and looks forward to discussing further new applications with trade visitors.

“Our composite machines also produce bi- and multiaxial non-crimp fabrics of glass, which are then further processed using the pultrusion method. The variety of materials and their laying angles offer exciting prospects for lightweight construction applications, which we would like to discuss with visitors at JEC,” says Kay Burkhardt, Product Manager at KARL MAYER Technical Textiles.