#Techtextil 2024

Pleva will showcase advanced technology for energy-efficiency and sophisticated processes at Techtextil 2024

Make complex processes transparent and efficient

“Processes become more complex, customer requirements higher & well-trained staff scarce. Technologies as sensors & controls gain importance for efficient operation. Our new process control system PLEVATEC pro is designed to meet exactly those needs. It enhances operation even at complex production lines with different modules, enabling our customers traceablility and easy operation to save energy and improve the product quality”, states Dr. Ralf Pleva, Managing Director.

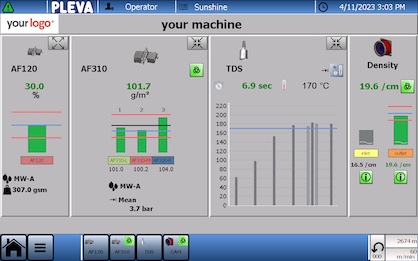

Textile producers make sophisticated processes transparent and efficient with PLEVATEC pro which allows an integration of a huge variety of process critical data with all information at one glance and optimal controls.

Hereby, tolerances can be set as well as parameters saved and loaded within the integrated recipe management system. The customizable system provides solutions to a huge range of processes, e.g. a production line with foulard, vacuum, predryer, coating and stenter frame.

An integration of the following PLEVA devices is possible:

- Exhaust humidity FSX for great energy savings

- Fabric/air temperature TDS for transparent drying/heat-treatment processes

- Residual moisture RR, RF/AF for improved fabric quality and efficiency

- Application moisture/coating AF for savings of valuable chemicals

- Pick/course density CAM for high quality fabric

The all seeing eye – CAM series 400

For the assessment of quality parameters but also weft-straightening, precise detection and advanced image processing is the most important aspect. The brand new CAM offers cutting-edge technology with many novelties for best results: Completely new lighting with increased brightness and special lighting possibilities allow a detection of all kinds of fabric - independent from density or color. On top, it is also designed as a retrofit for existing PLEVA systems with easy connectors and is fitted for even the harshest conditions thanks to an improved housing design.

Besides those new developments, PLEVA also offers special versions of sensors for special demands such as the TDS sensor for fabric and air temperature fitted for EX-zones, state of the art interfaces like Profinet and the PLEVA Remote Service for even faster support of your production. Whether for standard applications or demanding processes, PLEVA is your partner for the sustainable and efficient production of tomorrow.

PLEVA is looking forward to show its highlights in hall 12.0 booth C41 during Techtextil 2024.