#Nonwovens / Technical Textiles

Sustainable solutions at nonwovens - Reducing gas consumption at drying of spunlace production

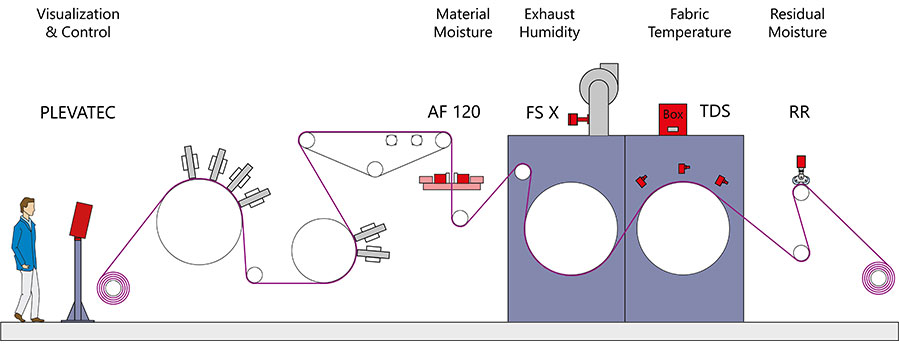

Thus, at their spunlace laboratory facility a measurement and control concept by PLEVA was implemented to optimize the process to highest energy efficiency. This includes sensors for residual moisture, fabric temperature, exhaust humidity, and a process control system.

Solutions installed at spunlace production line of STFI

AF 120 After the spunlace process, a contactless microwave moisture measurement with the sensor AF 120 is used due to the conditionally high residual moisture content. The sensor consist of 2 measuring heads, the transmitter and the receiver. The measuring principle is based on microwave absorption by the water content of the nonwoven. The more water there is in the nonwoven, the lower the signal at the receiver. The magnitude of the absorption is a measure of the absolute residual moisture content of the nonwoven.

This determination of the water content is used to optimize the subsequent dryer.

TDS Inside of the drum dryer, the nonwoven temperature is monitored with 3 TDS infrared sensors. This ensures that the quality of the spunlace nonwoven is not affected by overheating. The used infrared measurement is based on heat radiation exchange between the spunlace nonwoven and the infrared sensor. The measuring range of the TDS sensor is 0 - 250°C.

FS X The exhaust air humidity in the screen drum dryer is monitored by the FS X air humidity sensor and can be regulated in the production process via a exhaust flap control. The absolute air humidity (water vapor) in the exhaust exit tube of the drum dryer is measured. The setting of the optimum air humidity value should be e.g. 90 g water/kg air under production conditions for textile dryers.

RR For measuring the low residual moisture after the drum dryer and thus for controlling the fiber-dependent drying temperature, an RR sensor is used. It is used in applications of up to max. 30 % residual moisture. This sensor is a tandem roller sensor which monitors the residual moisture measurement in the center of the nonwoven. The active principle is the contact measurement of very low residual moisture based on electrical conductivity. The defined contact pressure and perfect alignment to the nonwoven with the tandem roller sensor ensure the highest accuracy. Another advantage is the compensation of electrostatic charge at low residual moisture levels and for fabrics with synthetics.

PLEVATEC With the process visualization, the fabric temperature, residual moisture and exhaust air moisture measured by the corresponding sensors are monitored and the process values are adjusted on the spunlace system. Andreas Nestler, Research Associate at STFI highlights the newly achieved possibilities: “The profile of the residual moisture after the AquaJet and the drying temperature (fabric temperature) allow new optimization possibilities in the drying process. Gentle heating curves become possible, which prevent nonwoven surface damage. Also, the process and tolerance monitoring enables the improvement of the nonwoven quality, as it is not exposed to unnecessarily high drying temperatures.” This is also an important aspect in terms of sustainability, as there are no more second choice goods or rejects, which implies savings of valuable resources.

Furthermore, a comprehensive 10-day trend display/history and recipe management is possible. The drying process is carried out with highest energy efficiency and continuous data monitoring. The process visualization is a modular visualization and control system for the material moisture and for the drying process. At various customer trials with this implemented system of sensors and process control, the goal of achiving an energy efficient nonwoven production line was achieved. With the used technology it was possible to lower the drying temperature by 40°C (from 100°C to 60°C) running on target moisture. For viscose the residual moisture was set to 5-7%. In sum with this optimizations a used gas volume reduction of 20% was achieved with a given full transferability to industrial dryers.

More information about sustainable solutions and PLEVA can be found on

http://www.pleva.org

https://www.stfi.de/en/research/nonwovens