#Techtextil 2022

Sustainability is the new functionality

The KARL MAYER Group ( Hall 12.0, C93) will be presenting itself at Techtextil from June 21 to 24 2022 in Frankfurt am Main as an innovative partner in the production of high-performance textiles. The global player can be found in Hall 12.0 on Stand C93. Innovative patterns and application examples of warp knitting and flat knitting will be shown.

More sustainability through solutions from the warp knitting industry

The KARL MAYER Group manufactures biaxial and multiaxial warp-knitting machines, as well as warp-knitting machines with and without weft insertion, on which functional articles for a wide range of applications are produced.

With its exhibition, the manufacturer joins the key theme of Techtextil: sustainability. For the composites industry, it presents solutions for the production of fiber-reinforced plastics made from natural fibers. The renewable resources are processed on weft and multiaxial warp knitting machines into reinforcement structures that open up completely new perspectives in terms of their environmental performance.

The textile innovation 4D-KNIT offers new possibilities for a better life cycle assessment of fashion articles and outdoorwear. The fabric for midlayer and softshell performance solutions scores with a sophisticated textile construction that leads to significantly lower fiber release during washing than when using double-sided raised fleece fabrics. Besides, a positive effect for the environment is a reduction in microplastic pollution.

Another focal point on the KARL MAYER stand is the topic of "Smart Textiles and Wearables". With the possibilities of jacquard and multibar patterning of warp knitting machines, electrically conductive yarns can be integrated directly and tailor-made into knitted fabrics in order to implement functional elements such as sensors, conductors and coils in an uncomplicated way. The textile properties remain unaffected. The potential arising from the seamless combination of electronics and textiles is being researched in the company's own TEXTILE-CIRCUIT unit. The latest results of this work will be on show at the KARL MAYER stand at Techetxtil.

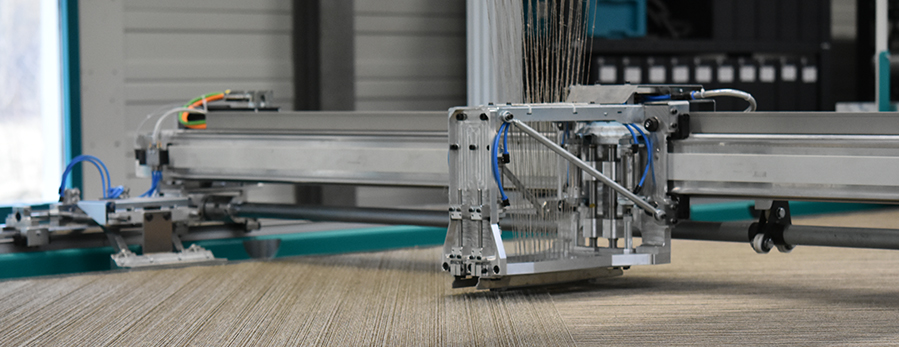

As an innovative pioneer, the Group is also working on forward-looking solutions in the field of additive manufacturing. The work under the heading RAPID TEXTILE focuses in particular on the combination of 3D printing with textile technology. In principle, the combination of the versatile printing process with traditional fabric formation technology offers new possibilities for production on demand. If only what the consumer needs is manufactured, this is also a contribution to greater sustainability. Techtextil will show how the 3D printing process can be integrated into series production.

For the first time, the KARL MAYER Group also has flat knitting innovations from STOLL in its trade fair baggage. The presentation will include solutions for waste-free production, the implementation of multifunctionality in a single process step, 3D shaping without additional work steps, and efficient knitting-on-demand production.

Minimize the ecological footprint with flat knits

For the first time, the KARL MAYER Group will also have flat knitting innovations from STOLL in its trade fair baggage. This business unit of the KARL MAYER Group will also be exhibiting samples on the themes of sustainability and recyclability. Both are basic requirements which the flat knitting technology meets excellently from the outset, for example with solutions for waste-free production, the implementation of multifunctionality in a single process step, 3D shaping without additional work steps, and efficient knitting-on-demand production.

For this purpose, STOLL will be showing current and innovative application topics from the currently important areas of bandage technology as well as shoe uppers and cover fabrics, which correspond 100% to the required expectations of sustainability.

In addition, special industrial and transport topics will be the focus of the exhibition. A wide range of synergies are expected from the first trade fair appearance under the umbrella of the KARL MAYER Group. For example, the STOLL team would also like to get to know the customers of other KARL MAYER business units and open up the wide product world of the entire group to its customers.