#Weaving

Solution for lower energy consumption proves itself in practice

Getzner Textil saves energy costs and CO2 equivalents when sizing with CASCADE, an interview from production operation

KHV: How do you rate the potential cost savings? Were you surprised by the results?

WE: The figures don’t look massive at first glance, but lots of little things add up in the end. Every contribution is important, especially in times like these. If we take the running time of the PROSIZE into account, the savings balance becomes even more interesting. The sizing machine can easily run for up to 20 years!

CASCADE also fits in with the path we have embarked upon as a company. We have strategically repositioned ourselves and made manufacturing costs a major focus. In markets that allow no price increases whatsoever, reducing production costs is an important factor for success – without compromising on quality, of course. To this end, we have drawn up an ongoing, cross-divisional overview of key topics and are implementing appropriate measures. CASCADE is one of our building blocks here.

In addition, the steam recycling system helps us to meet our obligations when it comes to audits. As a member of the energy efficiency network, for example, we are regularly assessed in terms of the improvements we have achieved.

KHV: Lower energy consumption means lower costs, but also a lower environmental impact. How important is this aspect?

WE: Sustainability is a key concern of ours. It is pursued not just by the Executive Board, but by the entire workforce and is firmly anchored in everyone’s minds. The CO2 footprint, for example, is also an important market criterion, especially in Europe.

We have already achieved a great deal, particularly in terms of the environmental impact caused by energy consumption. Optimising the compressed air supply in the weaving mill, for example, has saved around 1 GWh of electrical energy, and 11.3 GWh of our waste heat goes into a district heating network to heat the nearby schools, among other things. Our photovoltaic system supplies around 1.1 million kWh.

KHV: You are one of the first users of CASCADE. What motivated you to integrate a technological solution that had not yet proven itself in practice into your production?

WE: Our motto has always been “Curiosity is what drives us”. When we found out in autumn 2024 that our PROSIZE, which had just been ordered and specified, could be equipped with CASCADE, it was immediately clear to us: we’re going to go for it!

Being involved in the development of innovations right from the beginning gives us a certain head start in the market and means we can leave our mark. It gives us the opportunity to get customised solutions. For example, we were involved in the development of the PROSIZE itself. We frequently travelled to KARL MAYER Rotal in Italy for the conception of the centrepiece, a sizing box with a completely new application system, and contributed our technological expertise and even our ideas to the design. This was later followed by field tests at our premises.

The PROSIZE had already been running in Bludenz for nine months in 2014 before KARL MAYER presented the sizing machine at the following ITMA. The effort has paid off in full: instead of 150 to 200 litres of lost sizing at the end of production, we now dispose of only 15 to 20 litres. The filter system also ensures there is significantly less lint and dust on the warp and therefore greater efficiency in the weaving mill.

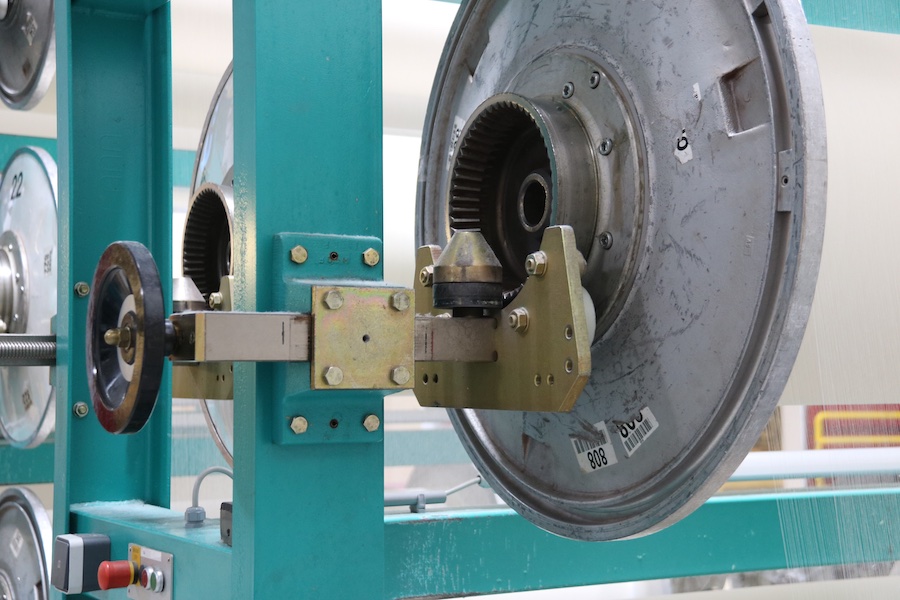

We were also interested in the MULTITENS yarn tensioning system at a very early stage. We had seen the technology at the ITMA in Munich and were sure that it would also be of benefit in cotton processing. The results of the first trial showed an increase in efficiency of 2% with an increase in speed of 100 RPM.

KARL MAYER is an innovative and reliable partner for us. What is more, the company listens to us and realises our technological requirements both precisely and promptly. For example, when we expanded our business activities to include technical textiles, we needed a small sizing kitchen for the special chemicals in this segment. We approached Enzo Paoli, President of KARL MAYER’s Warp Preparation Business Unit, and were provided with a solution that was exactly what we wanted. Another special technical solution for optimisation is already in our drawer.

Today, we rely 100% on KARL MAYER machines for warping, sizing and beaming.

KHV: Thank you so much for this interview – I look forward to further joint projects!

WE: So do I!