#Techtextil 2019

DORNIER will present latest solutions inspired by “The Green Machine” sustainability approach

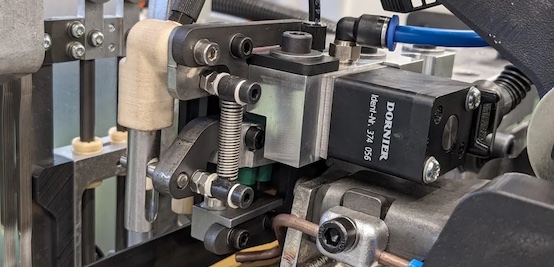

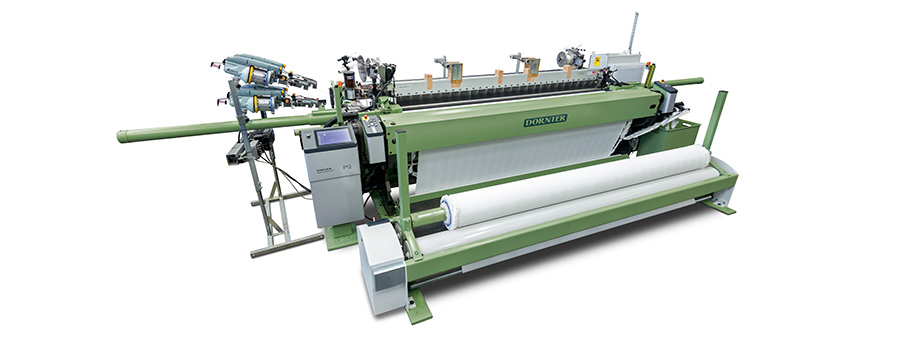

“Our machines are not just green on the outside”, declares Wolfgang Schöffl, head of the Weaving Machines product line at DORNIER. He is referring to the trademark green color of the machines from Lake Constance, which also serves as the visual equivalent of the company’s philosophy of sustainability, “The Green Machine”. In this way, DORNIER pursues a total approach which is applied systematically to all technological aspects from the machine to the woven fabric up to and including the finished product.” With regard to filtration, for example: The “Green Machines” are used to make ultrafine precision fabrics which are implemented in the service of environmental protection all over the world in filters for cleaning or preserving the cleanliness of air, water and exhaust gases. “We are constantly refining our equipment so that our customers can manufacture still more closely woven fabrics”, says Scho?ffl. Consequently, the last few years have seen a steady im- provement in filter quality: With the latest generation of P2 machines, a reed impact force of up to 50 kN and particularly the shed geometry optimized for technical fabrics are combined to produce wide air and water filter fabrics of very high density.

Conserving fuel with ease

The machines from DORNIER also weave with fuel economy in mind: For example, between 1990 and 2017 German airlines reduced the amount of fuel consumed for carrying passengers 100 kilometers by almost half. This impressive achievement is due in large part to the material favored by all engineers who wish to make their machines lightweight yet durable: carbon- fiber reinforced plastic (CFRP). Airbus and Boeing both began testing installing the first CFRP components in the early 1970s. These days, CFRP accounts for over half of the construction of the modern aircraft types such as the A350 XWB and the Dreamliner. But what hardly anyone outside the close community of the initiated knows: Weaving machines by DORNIER have represented the standard for working high-performance fibers such as carbon, glass and aramid for more than 50 years. And as environmental requirements become inexorably more stringent and every last gram is scrutinized intensely, these days even lightweight, ultra-strong primary structures such as turbine blades are produced on modern 3D Weaving Machines from DORNIER. Apart from aviation and space travel, the use of fiber composite plastics is also becoming more widespread in the construction industry (based primarily on the idea of replacing steel with carbon) and automobile construction. Incidentally, on the subject of cars: Two out of three airbags and three-quarters of all motor vehicle tires with textile reinforcement are made on weaving machines from DORNIER.

Constant development with sustainability in mind

But “The Green Machine” is not limited to just the “green effect” of the fabrics it produces. These “Made in Germany” systems enjoy an average service life of several decades, so they are exceptionally long-lasting, the opposite of disposable products. They represent the culmination of decades of experience in the design and manufacture of (rigid) rapier weaving machines and more than 25 years of expertise in the development of air-jet weaving systems. “It is our intention to remain constantly at the forefront of technical advance through innovation and to serve as a constant source of visions for sustain- ability with new machine concepts”, says Scho?ffl. Both air-jet and rapier machine are undergoing constant further develop- ment for the purpose of optimizing sustainability, he adds. Thus for example, the platform strategy, modular concept and global support network have made trusted, (energy-)efficient workhorses out of “Green Machines” as much as 30 years old for the modern weaver, more and more of whom are seeking opportunities in the growing market for technical textiles in addition to domestic and clothing fabrics. The following statement is intended to show that this philosophy of sustainability is not a mere passing trend at DORNIER, but rather the foundation of a long-term company strategy: “We strive to design and manufacture our products so that they are as safe and environmentally compatible as possible.” Is this an excerpt from the latest corporate brochure? Hardly. It is one of the seven guiding principles for the company – formulated almost 35 years ago by company’s founder Peter Dornier.