#ITMA Asia + CITME Singapore 2025

75 years of weaving machine manufacturing “Made in Germany”:

DORNIER celebrates its anniversary at ITMA Asia + CITME

At ITMA Asia + CITME, the leading exhibition for textile and clothing technology in Asia, DORNIER will be focusing on sustainable, digitalised and automated textile production. “We are consistently developing our weaving machine system family in terms of efficiency, energy savings and intelligent process monitoring”, says Wolfgang Schöffl, Head of the Weaving Machines Product Line at DORNIER. “That's why we are looking forward to presenting our latest developments to our customers in the technical textiles, clothing and home textiles sectors.”

P2 rapier weaving machine: Precise weft control with PIRO

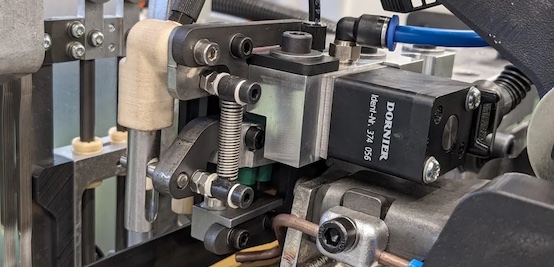

With the new PIRO system, DORNIER presents its latest innovation for the P2 rapier weaving machine. This allows each individual weft to be adjusted with pinpoint accuracy (‘pic-a-pic’). “With PIRO, the optimum release time for each weft channel can be set even for weft yarns of different fineness or elasticity”, explains Frank Seifried from the Technology Center Weaving Technique. “This considerably reduces weft waste and significantly improves fabric quality.” Since all PIRO data can be saved and retrieved digitally for each article, style change times are also greatly reduced, and reproducibility is increased. Manufacturers of technical fabrics such as industrial filters, geotextiles, conveyor belts and wire mesh benefit particularly from this. PIRO is available for all P2 rapier weaving machines – also as a retrofit.

Air-jet weaving machine A2: Intelligent process monitoring

In the field of air-jet weaving, the generational change to the A2 air-jet weaving machine is being driven forward at ITMA Asia. Like the P2 rapier weaving machine, the A2 is also based on the modular design principle of the DORNIER system family with standardised interfaces and individual machine designs. At the same time, the A2 represents a paradigm shift in terms of energy efficiency and productivity. Thanks to its redesigned main and relay nozzles with electronic air control, it offers manufacturers of awnings, airbags, tyre cord and carpets significant savings and quality advantages. “The intelligent process monitoring of the A2 ensures less downtime and energy- and air-saving weaving”, says Volker Janke from Product Development Weaving Machines. The ServoControl-2 touch panel provides a clear overview of all functions for monitoring the weft insertion and air pressure level.

Serial production of tapes and composites

In Singapore, DORNIER will also be presenting the latest advances in its plant systems for the serial production of modern fibre composite components. These include the PROTOS® TP tape production system for manufacturing unidirectional and fibre-reinforced tapes made of carbon, glass or aramid. Also on display is the PROTOS® TW tape weaving machine, which can be used to weave semi-finished products for thermoset and thermoplastic composite components from warp and weft tapes. The systems from the Composite Systems® division, which also include the TRITOS® PP 3D weaving machine, enable the economical series production of highly resilient, dimensionally stable and yet lightweight composites for demanding industries such as aerospace, mobility, medicine and sports.

DORNIER strengthens service and sales in Asia

Another focus at the exhibition is the expansion of DORNIER’s presence in Asia. The Chinese subsidiary ChinDO recently took over the entire sales and service division for Southeast Asia to provide even more targeted support to customers in the air and rapier weaving and composite manufacturing sectors in the future. At the same time, the regional sales team has been significantly expanded to further improve customer proximity and response times throughout Asia.

Change at the top of the weaving machine product line

For Wolfgang Schöffl, this will be his last ITMA Asia as head of the weaving machine product line. “After ten years with the company, I will be retiring at the end of the year. I am excited to look back on the milestones of the past and the innovative developments of the future together with our customers in DORNIER’s anniversary year”, says Schöffl. His successor will be Yvonne Schuberth. The trained textile specialist has previously headed the internal sales department for the weaving machine product line.

“Made in Germany”: 75 years of weaving machine quality from DORNIER

This year, the family business founded in 1950 by Peter Dornier, son of aviation pioneer Claude Dornier, is celebrating a special anniversary: for 75 years, DORNIER has stood for innovation, precision and quality in “Made in Germany” machine and plant engineering. The company caused a sensation as early as the 1950s with its first DoTex loom. However, the decisive technological change came with the introduction of the world's first shuttleless rapier weaving machine in 1967: Whereas until then, weaving shuttles, mostly made of wood, had passively transported the weft thread, in DORNIER’s new rapier weaving machine, two actively controlled rapiers transferred the weft thread directly. Today, this thread change takes place up to 600 times per minute – ten times per second. This leap in innovation fundamentally modernised the weaving of clothing, home textiles and technical textiles.

At the end of the 1980s, DORNIER succeeded in significantly increasing the productivity of air weaving by combining its own air weaving technology with Jacquard machines. Since then, DORNIER has been working closely with leading airbag manufacturers to develop pioneering weaving technology for flat-woven airbags and one-piece woven airbags. Today, DORNIER is a technology partner to the world's largest airbag manufacturers, for whom the weaving machines from Lindau are the industry standard. Thanks to their gentle and maintenance-free weft insertion, DORNIER air-jet weaving machines are also established as the benchmark worldwide among manufacturers of fine wool suit fabrics. DORNIER’s rapier weaving machines, which can process up to 16 different weft threads, are considered the technological benchmark by many manufacturers of sophisticated technical textiles and high-quality fashion.