#Knitting & Hosiery

Live more beautifully and comfortably with Warp Knits

Trends in home textiles for the coming interior design season

Stay cool – with silk-like blankets at bargain prices

The latest innovations include super-soft blankets with the high-quality look and feel of silk at the price of conventional mid-range counterparts and which are recommended for hot summer nights. The Q-max of these blankets is 0.24 W/cm². This parameter indicates how quickly a fabric dissipates heat from the skin when in contact with the body. In practice, a value above 0.2 W/cm² clearly indicates a cool feel. /1/

The cosy bedding is also breathable and easy to care for: it is simple to wash, dries quickly and does not crease.

The extraordinary blanket is based on a carefully designed warp knitted fabric. The textile for the cover around a filling layer consists of bright polyamide and elastane. It was produced on an HKS 2-SE in gauge E 36 using a suitable lapping and has an extremely dense, smooth surface. The compact structure emphasises the gentle sheen of the polyamide and gives it a cool feel. The elastane material ensures suppleness through stretch.

In addition to performance, this solution is also economical. The original bedding can be produced highly efficiently on the HKS 2-SE– a high-speed machine specialized in the production of elastic articles. Thanks to KARL MAYER's expertise, the machine can be adapted to the requirements for the production of blankets in standard sizes.

Corduroy reinvented: from classic stripes to turtle velvet

Warp knitted corduroy innovations are particularly exciting for home textile manufacturers. The distinctive ribbed structures are making a comeback – not only in fashion, but also in cushions, blankets and furniture covers. They are created by the interplay of threading and equal-length underlaps, which are cut and brushed after warp knitting.

This allows classic striped corduroy to be produced, as well as variants with different rib widths – through different threadings and underlap lengths – or faux fur effects for cosy blankets – through particularly long underlaps. The design of the underlap areas also offers scope for creativity, for example for corduroy patterns in turtle velvet style. For this design, reminiscent of a turtle shell, the underlaps are formed into square segments and arranged offset from each other along the sides.

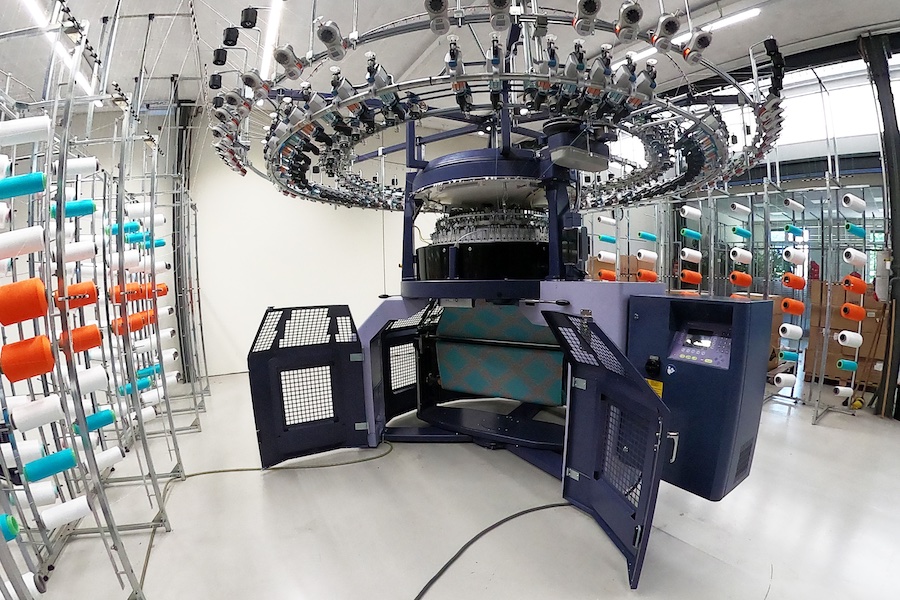

The HKS 3-M is particularly suitable for the flexible and efficient production of these corduroy articles. This high-performance warp knitting machine is one of the most flexible in the KARL MAYER product portfolio. It also produces velour and cuddly blankets, terry toweling and cleaning articles, as well as textiles for automotive interiors, sports and outerwear, mosquito nets, shoe fabrics and coating carriers.

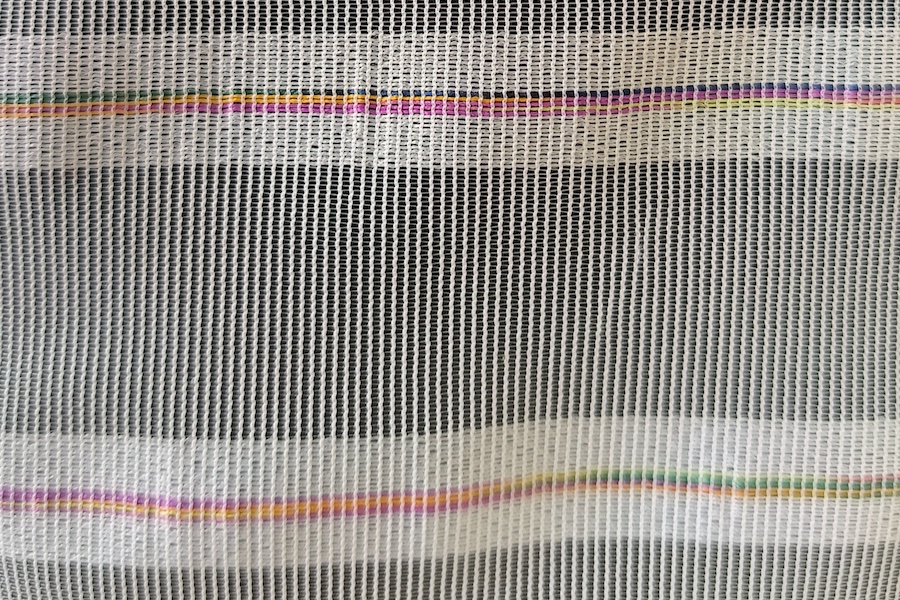

New curtain collection: Stripes with speed

A new curtain collection from KARL MAYER with fancy stripe patterns demonstrates the potential of Warp Knits for window decoration. The articles of the series were produced on a TM WEFT in gauge E 24 and feature striped segments of varying widths and densities. The variation is made possible by the choice of weft repeat and stitch density. The use of effect yarns provides even more design flexibility.

The production of the curtains is unbeatably efficient. Following an upgrade in 2024, the weft-insertion warp knitting machine is 20% faster than the previous version – a performance that is prompting many weavers to rethink their approach in order to reduce machine and personnel requirements.

Do you have any questions about the possibilities of warp knitting in the home textiles sector? Take advantage of your visit to Heimtextil in Frankfurt am Main to make a detour to KARL MAYER in Obertshausen, just a 20-minute drive from the exhibition centre.

Here, experienced specialists are available for discussions and selected best-selling machines are on hand for performance demonstrations. On display are an HKS 2-SE PLUS with extended pattern options, an HKS 3-M EL PLUS for net-like articles – including square marquisette and shoe fabrics – and a TM 3 as a flexible all-rounder with an optimised price-performance ratio.

Appointments can be made via this link:

https://forms.office.com/Pages/ResponsePage.aspx?id=wN-xQvoWVUme0yq53uw9Hp6EVE41oPtGtA5BADYEQ1BUOVA0S0dHTFRHVTlMSjFTN1NXNlFETzdJUS4u

or by email to:

Jonas.Richter@karlmayer.com