#Sustainability

Breakthrough technology developed – Acousweep separates microplastics from wastewater using soundwaves

Microplastic pollution is a globally established problem and a threat to ecosystems, animals, and people. Microplastics come from a variety of sources, including from larger plastic debris that degrades into smaller and smaller pieces, or microbeads in exfoliating health and beauty products, or cleansers such as toothpaste. A major source of oceanic microplastic pollution, about 16%-35% globally, comes from synthetic textiles.

As a philanthropic change agent for the entire industry, H&M Foundation acts with urgency and takes risks to unlock needed solutions with the ambition to find technologies that can contribute to a planet positive fashion future.

As a non-profit, we have the urgent opportunity to create change by supporting disruptive research that could lead us there. Innovation is transformation and Acousweep is proof that it’s worth investing in impatient research.

Christiane Dolva, Strategy Lead H&M Foundation

Professor Christine Loh, Chief Development Strategist at the Institute for the Environment, The Hong Kong University of Science and Technology, agrees that this technology has great potential.

Green tech has just taken a leap forward in Hong Kong. Acousweep will help the garment and other industries to stop a highly damaging form of pollution. HKRITA used a new technique to remove the microplastics by using soundwave-based system, preventing them from getting into the sea and being ingested by sea life that can even be ingested by humans along the food chain. Acousweep has the capacity to revolutionize industry.

Professor Christine Loh, Chief Development Strategist at the Institute for the Environment, The Hong Kong University of Science and Technology

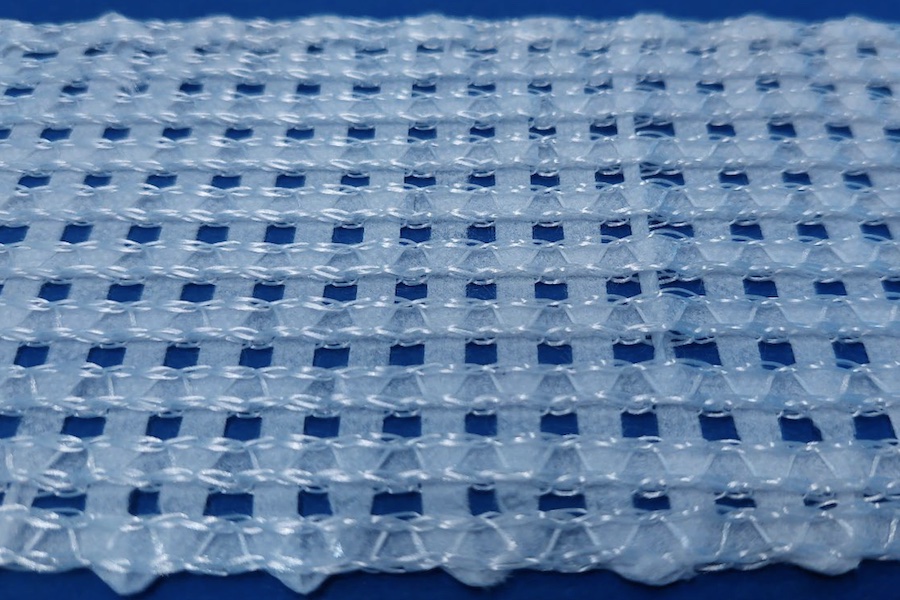

Acousweep utilises sweeping acoustic waves in a specially shaped chamber to physically trap and separate microplastic fibres from wastewater effectively. No chemical, solvent or biological additives are needed. The separated microplastics drip into a collection tank for further treatment, such as recycling. The existing lab scale treatment system handles 20 litres of water per hour while the upscaled version will be able to treat 5.000-10.000 litres of water per hour.