#Spinning

Ibrahim Fibres from Pakistan orders new cards for a flagship project

Pakistan is the eighth largest exporter of textiles in Asia and has the third largest spinning capacity in the continent. Ibrahim Fibres, located in Faisalabad, is a big contributor to that economic strength - and a powerful partner for Trützschler. The pioneering company produces a wide range of yarns for woven, and knitted fabrics. This includes various blends of cotton, viscose and polyester in different proportions and combinations with yarn counts ranging from Ne 8 to Ne 50. Ibrahim Fibres uses its own polyester via 240,000 spindles at four factories, mainly to produce poly-viscose and poly-cotton combed yarn. In total, the company manufactures 1,200 tons of PSF per day and consumes around 100 tons of its own materials per day. The remaining material is sold to other textile manufacturers.

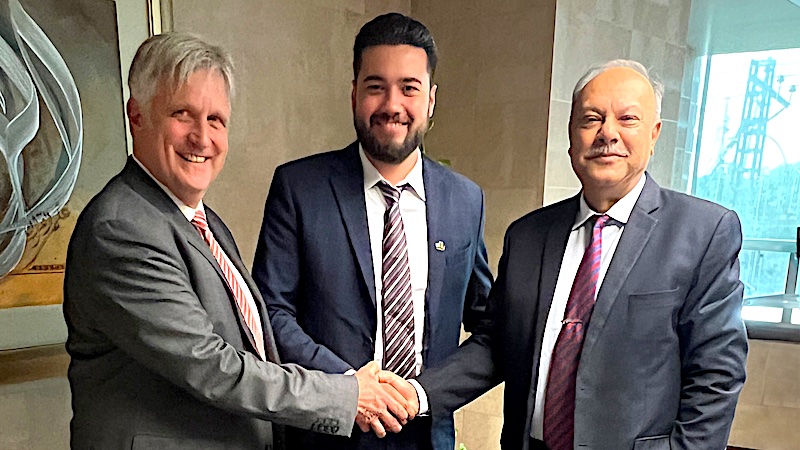

Trützschler's long relationship with Ibrahim Fibres is driven by a shared passion for continuous improvement, constant innovation and leading the push for more sustainability in the textile industry. "Our experience with Trützschler has been exceptional," says Zafar Iqbal, General Manager R&D and New Projects at Ibrahim Fibres. "Their high-quality machines, advanced technologies, and 360-degree analyses, along with innovations like MY MILL have been pivotal in our zero-man spinning and Industry 4.0 initiatives. Their excellent after-sales service over the past twenty years has built our trust and satisfaction. We eagerly anticipate continuing this successful partnership and exploring new opportunities together."

An unusual challenge Teams from Ibrahim Fibres often approach Trützschler with fresh ideas and new expectations. They recently set the challenge of producing top-quality yarns from unusually long polyester and viscose fibers. These fibers are used for luxury textiles, high-performance fabrics, fine bedding and advanced nonwoven materials. The end products benefit from the fibers outstanding strength and durability. Often, people in the textile industry talk about the problems with processing short fibers. But long fibers also present difficulties because they have a tendency to wrap or clog carding elements. Their length also makes them more tightly bound, which means they are more difficult to open.

What was the answer to this unusual challenge? Collaboration! Experts from Trützschler worked closely with partners at Ibrahim Fibres to explore potential solutions. "Our technical teams regularly collaborate with Trützschler’s R&D department to enhance production using Industry 4.0 principles, Al, and the latest technology," says Zafar Iqbal. "We’ve now developed a method for handling longer fibers that improves yarn consistency, end-product performance, and cost efficiency, while reducing waste. Our ongoing partnership with Trützschler continues to drive innovation and efficiency in our operations."

TC 30Si is here to help... Ibrahim Fibres wanted to process 51mm polyester with 51 mm viscose fibers. In line with these requirements, Trützschler engineers optimized the TC 30Si carding machine for processing long polyester and viscose fibers. This machine is specifically customized for man-made fibers and can process these fibers more effectively due to its larger drum diameter, which results in a 14 % extended carding length. The machine also has 35 % more active flats. It has one licker-in and its cylinder, doffer wire, flat tops and stationary flats are all designed for processing man-made fibers. "We chose TC 30Si for its advanced features, such as its 1400 mm cylinder diameter, extended carding lengths, and the automatic T-GO gap optimizer," says Zafar Iqbal. "These attributes support our Industry 4.0 goals by enhancing technology integration, data use, and operational efficiency, making it ideal for modernizing production and staying competitive in the textile industry."

And Ibrahim Fibres has even more reasons for choosing the TC 30Si: "It has user-friendly software and an intuitive Human Machine Interface (HMI), making it easy to maintain with minimal adjustments. This card boosts productivity and reduces energy consumption, while also improving consistency and reducing defects."

Long fibers, long partnership

This shared success is the latest milestone in the long relationship between Trützschler and Ibrahim Fibres. It's also a powerful example of how they work together to keep pushing the boundaries of what's possible. Based on strong test results, the customer placed an order for eighteen TC 30Si carding machines in June 2024. In this way, the company can move ahead with its big ambitions for processing unusually long fibers – and move ahead with the next phase of its long partnership with Trützschler too.