#ITMA Asia + CITME 2024

Trützschler will unveil latest carding technology for China at ITMA Asia 2024

Trützschler Spinning

At this year's ITMA Asia, Trützschler Spinning will present the newest carding technology for China. Details about this innovation will be disclosed at the show. Visitors should not miss the opportunity to experience this new technology first hand. Experts from Trützschler’s Spinning business unit will also present the third generation of the Integrated Draw Frame, the IDF 3. And of course, the teams will also stand prepared to give up-close insights into the world’s first 12-head comber, the TCO 21XL. These innovations achieve higher efficiency, lower energy consumption, digitalization and intelligent automation for fiber processing in spinning mills. The technological expertise enables customers to boost value and profit by producing sliver with higher levels of quality at outstanding production speeds.

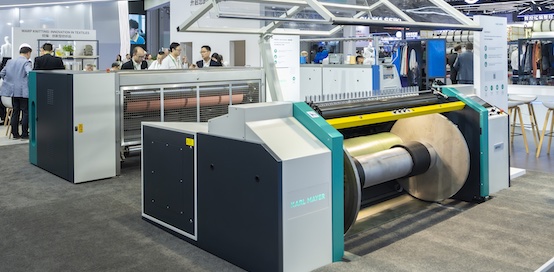

Trützschler Nonwovens

Representatives from the Nonwovens business will showcase solutions for more sustainable wipe materials made of pulp and other fibers from renewable resources. This includes results from trials of bamboo pulp combined with viscose/lyocell fibers to make fine baby, body and flushable wipes with mechanical, haptic and visual properties comparable to traditional paper-grade NBSK (Northern Bleached Softwood Kraft) pulp. Bamboo is fast-growing and can be harvested after just three years. That makes it a more sustainable alternative to pulp from softwood trees like pine, spruce or larch because those trees take decades to grow – so harvesting them has a larger negative impact by depleting forest resources.

The teams will also put a spotlight on Trützschler’s market-proven technologies for Wet-Laid/Spunlace (WLS) and Carded/Pulp (CP). These processes have proven effective in creating cost-efficient, biodegradable nonwovens for flushable wipes and single-use wet wipes.

Trützschler Card Clothing

Last but not least, Trützschler Card Clothing (TCC) will present a wide range of their comprehensive service portfolio, demonstrating how the combination of expertise in clothings, wires and service will bring machinery performance to the next level.