#ITMA Asia + CITME 2024

Successful warp knitting machines and textile show to master the changes of our time

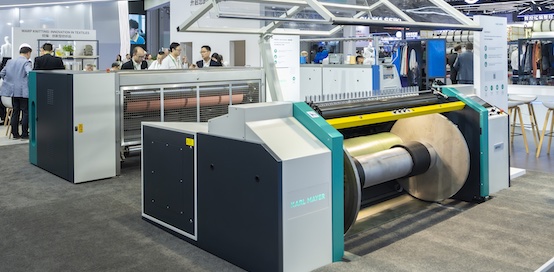

KARL MAYER Warp Knitting Business Unit draws positive conclusions after ITMA ASIA + CITME 2024

The exhibition was a major crowd puller at the KARL MAYER GROUP stand in the Shanghai National Exhibition and Convention Center. Around 40% of all visitors with specific inquiries came from the warp knitting sector. The number of guests was significantly higher than at the previous ITMA ASIA + CITME, especially on the second and third days of the event, and all major customers were present. Christof Naier, President of the Warp Knitting Business Unit at KARL MAYER, is delighted with the high level of response, but also with the quality of the exchange. “For the most part, we had very in-depth, goal-oriented discussions and conversations about many projects. Our customers are cautious but optimistic about the future,” says Christof Naier.

The visitors were particularly interested in the HKS 2-S presented in the new gauge E 44, its advantages in the production of sun protection clothing and the diverse textile and application show with its potential for more business.

In addition to the ITMA stand, a performance demonstration of selected machines at the in-house show accompanying the trade fair at KARL MAYER (CHINA) was also impressive, with two premieres. New in Asia and an attraction were the Elastomeric RE 4-1 with the 190” working width and E 36 configuration and the DM 6/2-6 EN, a double raschel machine with an excellent price-performance ratio.

Machines for markets with potential

With its efficiency and fine textile products, the HKS 2-S in E 44 brings new drive to the outdoor wear segment. At a maximum speed of 3,200 rpm, the high-performance tricot machine can produce up to 200 kg of fabric per day, extremely reliably and with the highest quality. The E44 articles in the HKS 2-S range are uniquely light, soft and supple, breathable and particularly suitable for use in sun protection clothing, i.e. for outdoor activities. Their UV protection factor more than doubles that of circular knitted fabrics with a comparable fabric weight. This is due to the dense surface structure.

The RE 4-1 is predestined for the extremely efficient production of highly elastic textiles. The machine offers an excellent price-performance ratio and therefore benefits that are particularly evident in the production of fine underwear items for the volume business thanks to the new 190” E36 combination.

With the DM 6/2-6 EN, KARL MAYER has further differentiated its range of double raschel machines and thus better tailored them to market requirements. With a speed of 850 rpm, the new machine works just as fast as its range neighbours, the RD 6/1-12 EN and RD 7/2-12 EN. However, thanks to a special technical focus on the production of lightweight 3D warp knitted fabrics, it is significantly cheaper. This makes the DM 6/2-6 EN a top production machine, especially when it comes to the highly efficient production of spacer fabrics for the luggage and furniture sector.

New textile developments with a focus on growth

KARL MAYER machines are not only extremely productive and reliable, but also open doors to new business with the right textile products, as demonstrated by a highly acclaimed textile innovation show at KARL MAYER's ITMA stand in Shanghai. The most important highlight was certainly a chic sun protection outfit made from an E-44 fabric from HKS 2-S. However, inspiration and ideas for new articles and applications were also provided by the other exhibits, including functional, fashionable sportswear for the growing yoga trend and clothing fabrics with the look of typical cotton fabrics, an E40 warp knitted fabric as an outer fabric for thick down jackets, a comfortable casual wear outfit, lace with a uniquely high approximation to the Leavers Lace standard, a RASCHELTRONIC® article made of silk and stylish spacer fabrics for clothing and shoes.