#ITMA Asia + CITME 2024

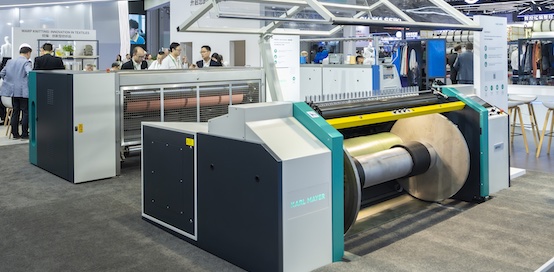

KARL MAYER Technische Textilien at ITMA ASIA + CITME - a presentation that opens up many opportunities

More business with composites, greater efficiency in warp knitting with weft insertion

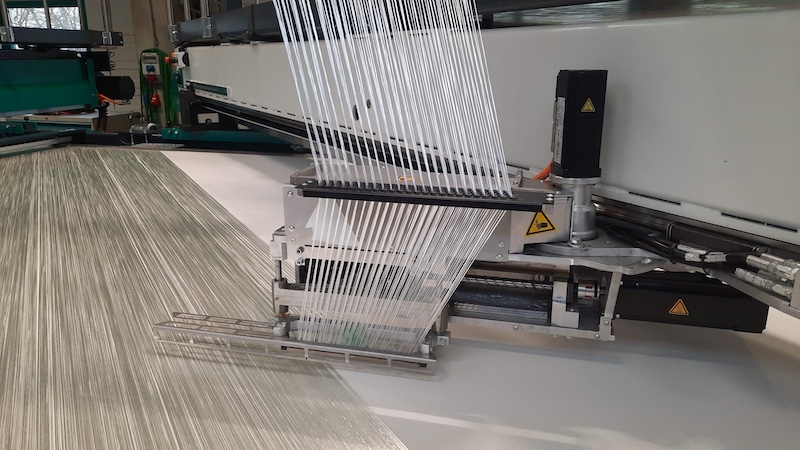

At an in-house show accompanying the trade fair at KARL MAYER (CHINA) in Changzhou, there was also a performance demonstration of innovative warp knitting machines with weft insertion with a 2nd generation TM WEFT and the new WEFT GRID ECO. Thanks to its special performance, the newcomer focuses on the production of lightweight glass fabrics for use in the construction industry, for example as plaster grids or crack tape.

Multiaxial non-crimp fabrics for a high-margin market

The response to the two exhibitions was not as high as at a typical technical textiles trade fair. In particular, the number of visitors from countries outside Asia was below the expectations of Jan Stahr, Regional Sales Manager of KARL MAYER's Technical Textiles Business Unit. Nevertheless, the market expert draws a positive conclusion. “We held numerous high-quality discussions with different customers. Among them were a surprising number of traditional warp knitting companies who talked to us about entry opportunities in the carbon composite sector,” says Jan Stahr.

The reactions to the samples of non-crimp fabrics exhibited in Shanghai and to the application video shown met all expectations. Particularly pleasing was the visit to the KARL MAYER stand by an up-and-coming carbon composite player, which is characterised by a high willingness to innovate. Representatives of his top management came to exchange ideas. The reasons for the great inter-est in carbon fiber-reinforced composites are, on the one hand, the affordable raw material prices since China's entry into fiber production and, on the other hand, an increased demand for light-weight components, especially in the field of e-mobility. The carbon composite business attracts newcomers and those switching to it with higher margins than in the glass fiber reinforcement seg-ment.

There was also a promising exchange about the MAX GLASS ECO. The reliable production machine for the extremely economical production of standard articles made of glass fibers is particularly interesting for the wind power market, which is currently picking up speed again in China and India after years of consolidation. The timing of the machine presentation via video and with samples could not have been better!

Warp knitting machines with weft insertion with market tailoring

Another crowd-puller was the TM WEFT for the in-house show at KARL MAYER (CHINA). Many visitors took the opportunity to see the performance of the highly efficient machine for themselves - thanks to a targeted upgrade, the new version is 20% faster than its predecessor. Some customers also decided to invest during the event. Demand is being fuelled in particular by the trend-driven fashion sector. “We are seeing more and more outerwear fabrics being produced at TM WFT instead of interlining articles,” explains Jan Stahr. In line with this development, the exhibition machine in Changzhou produced a chic ocean wave fabric with striking 3D surface effects. TM WEFT customers include many weaving companies that have been able to reduce their machinery and there-fore their personnel requirements by switching to the highly efficient warp knitting machine with weft insertion.

Confirmation from the market

The new WEFT GRID ECO aroused interest due to its price-performance ratio. It achieves a working speed of 1,800 rpm and has convinced customers to conduct performance tests in their pro-duction in the coming weeks. However, the growth impulses from the construction sector, the main customer for WEFT GRID ECO products, is still below expectations.

The feedback from the presentations at ITMA ASIA + CITME 2024 confirms that KARL MAYER's Technical Textiles Business Unit is on the right track.