#Spinning

Trützschler Group at CAITME 2024

Trützschler Spinning

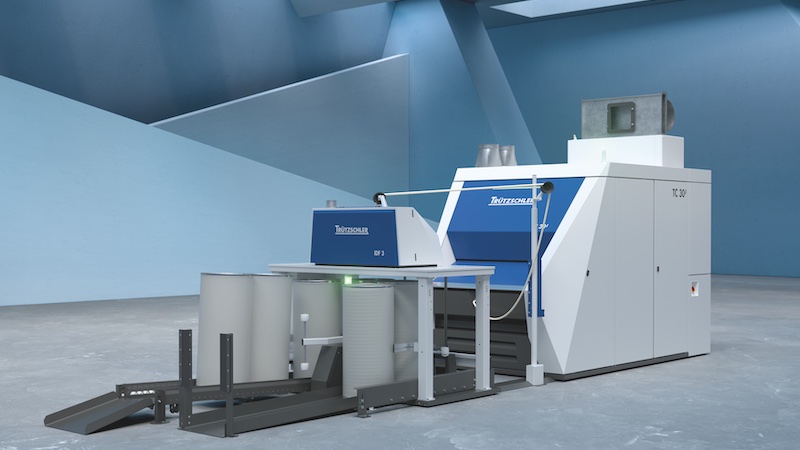

Discover the latest innovations in carding, draw frame and combing at Trützschler Spinning. All innovations address fundamental customer needs in fiber processing: high efficiency, more sustainable raw material utilization and intelligent automation. A highlight will be Trützschler’s next generation card, the TC 30i. In recent customer trials, the TC 30i has achieved up to 40 % higher productivity while reducing energy consumption by up to -18 %. In addition, the team will share insights about the Integrated Draw Frame IDF 3, which enables shortened processes that save resources, energy and production space. Visitors will also have the opportunity to discover the world's first 12-head comber, the TCO 21XL. This new high-performance comber makes it possible to increase productivity by 50 %, while requiring 25 % less space and achieving consistent quality at all times.

Visitors will also get the chance to learn about Trützschler’s new brand for textile recycling, TRUECYCLED. Through machinery expertise and technological know-how, the company enables its customers to produce high quality tapes while turning waste into value.

Trützschler Card Clothing

Trützschler Card Clothing (TCC) will present a wide range of technologies from its card clothing portfolio, covering the full spectrum of applications in the spinning and nonwovens markets. A key feature will be the Flexible Bend Control (FBC), which ensures perfect flat setting for all card models within a few seconds and guarantees optimum quality at all times.

Trützschler Nonwovens

Trützschler Nonwovens will focus on proven solutions for the production of cotton nonwovens for wipes, pads and medical products from virgin fibers, comber noils or blends. In addition, the team will provide insights into T-SUPREMA needle-punching lines and will be ready to show you its solutions for the specific requirements of high-potential markets such as geotextiles, filter media, automotive textiles or other durable products.

Meet Trützschler in Tashkent, Uzbekistan!

CAITME offers a great opportunity for people from across the textiles industry to talk to the spinning, nonwovens and card clothing experts. The Trützschler people are already excited to meeting you in Tashkent, Uzbekistan, at pavilion 3, booth J30.