#Spinning

TC 30i: Convincing customers with strong results

Higher productivity, less energy consumption

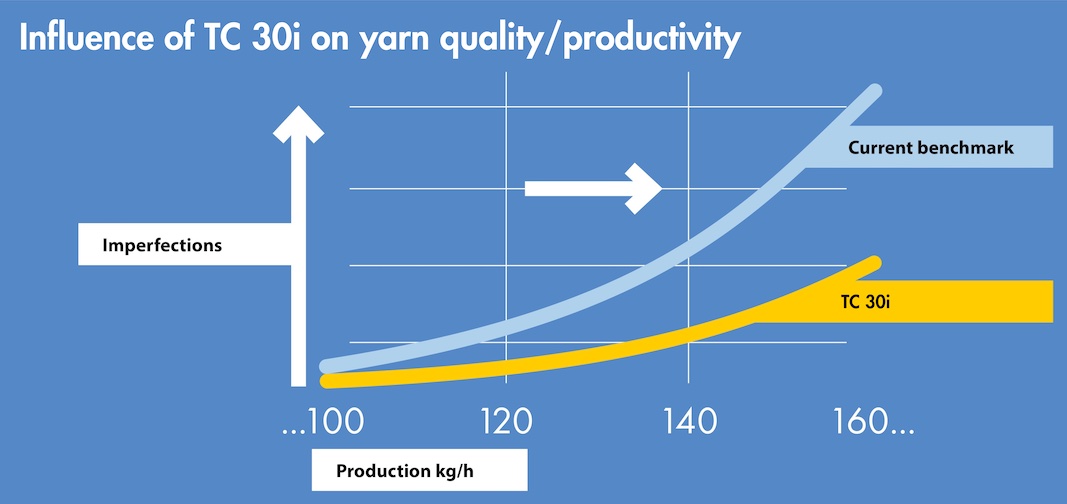

Mayfil Tekstil is a leading company in the Turkish textile industry for the production of textured yarn. It is headquartered in Nilüfer/Bursa. Founded in 2005, it has grown rapidly by prioritizing customer satisfaction. In 2022, Mayfil invested in a modern vortex airjet spinning facility that can produce up to 35 tons per day. And the company was keen to take a close look at the TC 30i for man-made fibers to explore its potential to drive progress toward Mayfil’s ambitious growth plans. In February 2024, Mayfil Tekstil conducted tests with the TC 30i. The next-generation carding machine produced 140 kg/h viscose, which is more than 40 % higher than the 95 kg/h Mayfil produces with the current benchmark. The new carding machine also decreased electricity consumption by 18 %. Based on these results, Mayfil is purchasing further TC 30i cards.

Results confirmed

Göl Iplik Seremet Tekstil Sanayi ve Ticaret A.S., located in Inegöl Bursa, operates three factories that deliver a variety of high-quality products, with a specialization in blended yarns. Investment in modern equipment and pioneering new products that expand its portfolio are at the heart of Göl Iplik’s success across almost four decades. Göl Iplik also tested the TC 30i for man-made fibers in early 2024. This Trützschler customer took a close look at the TC 30i during rigorous viscose trials. The TC 30i achieved a 40 % higher productivity rate with the same level of quality, while consuming 15 % less power. Göl Iplik now intends to include the TC 30i in its future investment strategy.

Promising feedback

The TC 30i is still a newcomer in the textile industry – but its reputation is growing rapidly as spinning companies around the globe experience its range of smart features and functions. Its contributions to productivity, quality and resource efficiency are convincing. More and more companies around the world are now ordering our TC 30i. We are happy to convince more customers worldwide.

Benefits of the TC 30i:

1) Best quality from any raw material: High levels of productivity and yarn quality thanks to 35 % more active flats, the longest carding length in market and the T-GO automatic carding gap optimizer.

2) Operator-independent performance: Consistent results without relying on manual operators thanks to automatic, real-time optimization of the carding gap with T-GO.

3) Value-adding waste handling: Innovative waste suction system collects and separates different types of waste. More than 50 % of card waste can be reused or sold to third parties for an attractive price.