#Spinning

Opening up infinite possibilities for Industrial Yarn

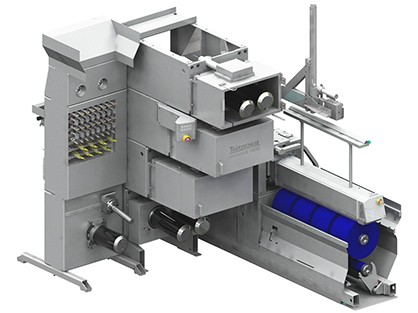

Since 2012, Trützschler has been developing and building high-performance extrusion lines for Bulk Continuous Filament (BCF) carpet yarns (our MO40-C, MO40-E and TO40 machines). Trützschler launched the OPTIMA concept for BCF in 2019 and has firmly established a strong market position since then. At the same time, we started work on innovative solutions for industrial/technical yarns made of polyester, polyamide and polypropylene.

Modular design

OPTIMA was designed as a modular platform that uses proven components. It now features two new solutions for manufacturing industrial yarn – the TEC-O40 and the TEC-O80. Both OPTIMA for IDY systems offer impressive flexibility and can meet the needs of a diverse range of applications and throughput requirements.

These modular-build draw frames allow for the integration of three to five duos of heated godets:

• Semi-industrial yarns for durable products such as bags, backpacks or shoelaces are produced on a three-duo system.

• The concept with four godet duos delivers high and super-high tenacity yarns for belts, nets and ropes.

• Five duos are used when producing low and super-low shrinkage yarns. Typical applications include coated broad-woven fabrics (tarpaulins, billboards or airbags) and tire cords.

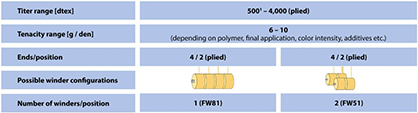

TEC-O40

Two TEC-O40 systems cover the entire industrial and semi-industrial yarn market. They target high and/or super-high tenacity products, as well as super-low shrinkage yarns.

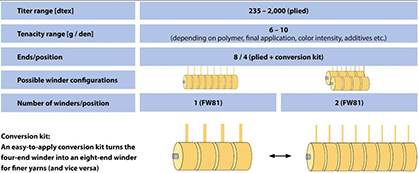

TEC-O80

TEC-O80 systems serve the low-to-medium denier yarn market. To add flexibility, an easily adaptable conversion kit can turn a TEC-O80 draw frame into a TEC-O40 system. This opens up the product range to include higher dtex yarn qualities.

Excellent extrusion

Customers in the man-made fibers market are now benefitting from these two additional OPTIMA extrusion systems. The TEC-O40 and the TEC-O80 offer outstanding flexibility through their modular construction, which enables manufacturers to adapt the equipment to serve changing needs and demands. The innovative systems are another clear indication of Trützschler’s constant focus on developing solutions that deliver better quality, improved efficiency and a valuable competitive advantage.