#Spinning

Spinners know what they want

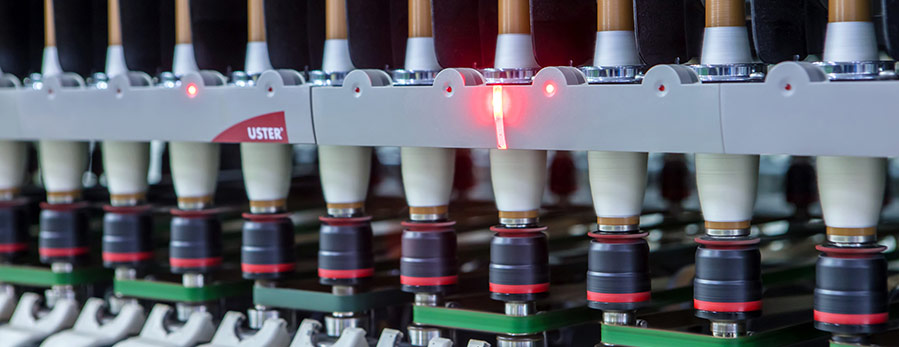

An ambitious spinner was aiming to reach the next level of quality management. For this customer, it was essential that quality, as well as profitability, had to be improved. The medium-sized spinning mill in India installed Uster-Muratec RSO 3D as part of an expansion project. The installation includes 30 compact ring spinning machines with Uster Sentinel, in combination with Muratec QPRO EX/FPRO EX featuring Spin Inspector and Uster Quantum yarn clearers. On these machines, the customer produces 100% combed cotton yarn, in counts Ne 26 and Ne 32.

Advantages in percentages

When the new installation was being started up, a direct comparison between RSO 3D and the standard installation was executed as a trial to demonstrate the difference.

The evidence showed that the spinner was able to reduce yarn faults by 10% and yarn alarms by 12% in both counts with RSO 3D. Quality blocks were reduced by a further 7% and finally clearer quality cuts by 8%.

Overall, this spinner was able to reduce the total yarn splices by 5%, producing about 5 kg more good yarn per machine per month.

Money talks, clearly

The mill’s results are impressive. Some small calculations convert the facts into numbers. Let’s start with energy savings. By reducing yarn joints on the winding machines, the customer needed less compressed air and thus less electricity for the machine compressor unit. These savings together amount to approximately 954 kWh per machine per month. Calculated at about 0.08 USD (6 INR) per kWh, this comes to 77 USD (5,724 INR) per machine per month. With 30 machines, this amounts to 27,720 USD (almost 2 million INR) the whole year.

On top of the financial savings, the mill also noted an increase in the level of ‘good’ material. The 5 kg reduction in waste means there is 5 kg more good yarn per machine every month which can be sold. With 30 machines, this totals 1800 kg more yarn per year. Based on a price of 3.77 USD (280 INR/kg), this achieves an increase in sales worth another 6,786 USD (500,000 INR).

Combining both these calculations, the overall gain for the spinner totals 2.5 million INR per year, equivalent to about 35,000 USD/year, apart from significant savings due to reduced clearer cuts.

Further advantages can also be expected in downstream processes. Fewer cuts mean the yarn has fewer potential weak points leading to less stoppages due to yarn breaks. This makes it possible to adapt subsequent process speeds, while the customer will also benefit from an improved fabric appearance.

Operators benefit too…

The working area for machine operators could be increased significantly – while reducing the stress factor. This is possible because Uster Sentinel notifies the operators from a distance about individual yarn breaks. The system uses signal lamps at the head of the machine, at the relevant section, and at the affected spinning position. So, the operator is logically guided to the next yarn break, instead of having to search laboriously for yarn breaks along all machine sides.

When an operator locates a yarn break, the type of break is indicated at the spinning position. Different signals categorize the problem as either Slip, Off Quality, Rogue or RSO 3D alarm. At this mill, operators are instructed to deal exclusively with yarn breaks, but not with the RSO 3D alarms. These are the responsibility of highly-trained technicians, because RSO 3D alarms indicate a faulty setting at the spinning position, and repairing them is both necessary and time-consuming. The RSO 3D alarms are displayed to the technicians by the Sentinel LEDs, and also on the Quantum control unit (CCU), as well as on the RSO 3D Quality Map.

As a result, the customer can deploy trained personnel in a very targeted and efficient manner. At the same time, the mill could increase spinning capacity and the working areas of the operators through path optimization.

Rapid payback

Individual quality data for each spindle position enables quality mapping across the ring spinning machine. This helps to identify outlier sides, sections or spindles, in addition to supporting maintenance decisions. Quality mapping also enables users to trace problems back to the individual roving machine and bobbin. Thanks to quality mapping, spinners can keep the entire ring spinning machine under control – and their profits as well.

RSO 3D proves its worth, for every cent invested, because of cost savings through reduced compressed air use and savings in energy. Payback comes earlier with the higher production efficiency based on saving cuts. It means the extra amount of good yarn sold is equal to what would have otherwise been wasted at the winding machine.

“The customer is convinced of Uster RSO 3D because of the increased spinning productivity and profitability, as well as facing the challenge of the lack of well-skilled staff by utilizing trained personnel in a very targeted and efficient manner,” says Amol Kekre, General Manager Sales & Marketing at Uster’s subsidiary in India.

Bigger profits come with increased quality standards, because of much smoother running at the winders. Claims are a thing of past and increased production efficiency assured for the future. The spinner’s downstream customers will also be delighted to increase production speed in their own processes – and to improve fabric appearance at the same time.