#Spinning

My Shop – Truetzschler service never sleeps

“My Shop”, along with “My Mill”, “My Production” and “My Wires”, is one of the digital solutions that are brought together under the “My Trützschler” umbrella platform. The global identity service “My Identity” provides the key to the entire digital Truetzschler world: Once you have registered, you can access all available Truetzschler online applications simply.

The “My Shop” application promises customers of Truetzschler Spinning and Truetzschler Card Clothing a varied product range and a straightforward, practical process: When accessing the online shop, the customer – or customer representative – is directed to the relevant page of the Spinning or Card Clothing shop because the system automatically assesses requirements based on the user’s identity. If the user is matched to both areas, they can simply select between “My Shop Spinning” and “My Shop Card Clothing”.

“My Shop” for Card Clothing customers:

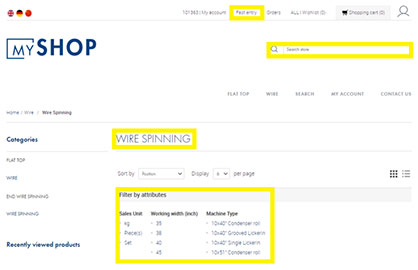

Card Clothing assessable 24/7: The newly implemented TCC online shop allows customers to make clothing orders at any time and from any location. Various search and filter functions are available to help select the right articles. In this way, individual product areas can be selected, for example. In turn, this allows a selection based on further attributes like sales units, working width etc. By narrowing down the product range, this filter makes selection much easier because only articles that are relevant to the customer are shown.

The standard search box provides an alternative that allows users to search for terms or product characteristics. If the customer already knows the exact article number, we recommend using the “Fast Entry” tab.

In addition, the online shop also indicates which items are available in stock, or whether they still have to be produced, as soon as the customer selects the articles. In this way, the user immediately gets an idea of the delivery time.

“My Shop” for Spinning customers

Since 2019, Spinning customers have been able to enjoy the practical and easy-to-use online shop. Just like the Card Clothing area, the Spinning online shop offers “Fast Entry”where spare parts can be ordered directly: Users simply enter the article number, machine name and year of manufacture, together with the required quantity of components. They can also make a note of spare parts at any time: If the customer knows roughly when the next machine maintenance is scheduled, for example, they can simply add the required products to their own personal wish list and then reorder them on time when required.

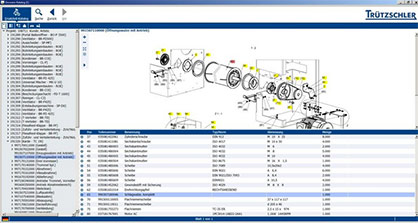

Individualization is another major benefit of the Spinning online shop: The online spare parts catalogue, for example, is tailored perfectly to the customer when signing in. This means the customer only sees products that are relevant to their own personal machine configuration. A table list of all of the objects used, including product drawings and further detailed information like the dimensions and costs of machine components, rounds off the catalogue function. This enables the users to find the required spare parts and the respective article numbers simply, quickly and precisely.

Global Parts Service

With the “My Shop” platform Truetzschler provides its customers with an around-the-clock service for the Spinning and Card Clothing divisions. Its customer representatives are happy to take care of the coordination and handling of the order for the customer, while the Global Parts Service is available as a contact at all times and checks incoming orders individually to make sure that they are correct and complete. This empowers Truetzschler to meet its own quality demands for tailor-made customer service. The company is constantly working on further digital applications to expand its service range further in the future.

The benefits of the “My Shop” online shop at a glance:

• Quick and easy order placement

• Access from anywhere

• Maximum reliability

• Quick delivery

• Simple administration

• Personal contact: Global Parts Service