#Spinning

New TC 19i delivers outstanding results

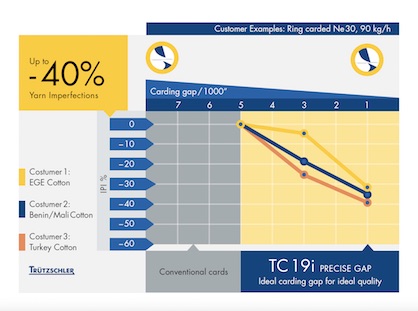

- Up to 40% less yarn imperfections

- Up to 2% raw material savings

- Several hundreds of intelligent cards sold since launch in January

Intelligent functions improve quality, productivity and raw material utilization

“With the new intelligent card, we can achieve consistently high quality and productivity with very little effort”, confirms MD Moshiur Rahman, General Manager at Badsha Textiles Ltd. in Bangladesh. Badsha Textiles Ltd. is a leading textile conglomerate and producer of a range of high-quality carded, ring and open-end yarns in state-of-the-art spinning mills. The company trusted Truetzschler to deliver on its promises regarding the performance of TC 19i – and has not regretted its decision yet. In a production of cotton ring yarn, for example, the TC 19i achieved a reduction of yarn imperfections of minus 35% at a production of 90 kg/h. MD Moshiur Rahman explains: “The gap between cylinder and flats is crucial to ensure quality. In conventional machines, the minimum gap which we could get was 3 thou (thousandth of an inch). The TC 19i makes it possible to get 1 thou.“ Keeping such narrow carding gaps, which are thinner than a piece of paper, is decisive to achieve maximum quality and productivity, especially in processing cotton. Moreover, this process has become fully automatic: “Before using TC 19i, skilled technicians had to optimize the gap after dismantling the machine. But now it is done using software efficiently and precisely. The advantage of quality adjustment in a running carding machine was quite unimaginable before. With TC 19i it can be done effortlessly“, says MD Moshiur Rahman.

At the same time, the new card allows raw material savings of up to 2% - and this by just one click on the card’s display. “Before we worked with TC 19i, my team spent quite some time on inspecting the card waste regularly and adjusting the knife settings” reports MD Moshiur Rahman. This is now a thing of the past: The TC 19i with WASTE CONTROL monitors the carding waste, gives recommendations and adjusts the knife automatically.

In other key textile markets, such as Turkey, Uzbekistan, and Mexico, the TC 19i demonstrated similar significant advantages in terms of quality, productivity, raw material savings and handling and energy efficiency. It showed up to 40% less yarn imperfections in carded ring yarn, and even more than 50% less yarn imperfections in combed ring yarn and rotor yarn manufacture – and this at high production levels between 75kg/h and 100 kg/h.

“We observe that our customers create more value from their raw material with the TC 19i, and are able to increase productivity and quality flexibly” reports Markus Wurster, Global Sales Director at Truetzschler. “Moreover, the results are independent of technician, temperature, wire condition or production rate”. Only a few clicks on the display are necessary, and the intelligent card sets and keeps the ideal carding gap automatically and permanently.

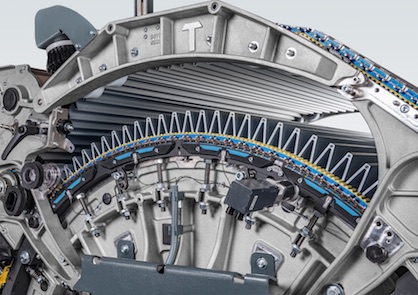

Advanced sensor technology: T-GO gap optimizer

“At the heart of the intelligent card is the T-GO gap optimizer” explains Armin Leder, Director of Truetzschler’s global R&D department. “In combination with our T-CON sensor system it enables our card to know and adapt the real carding gap at all times during operation and under changing production conditions. No competitor card can achieve this. The TC 19i is the first intelligent card and an economic and ecologic solution for the demands of state-of-the-art spinning preparation.”